a kind of wo 3 /fe 2 o 3 /mn 3 o 4 Preparation method of composite photoanode film

An anode film, composite light technology, applied in electrodes, liquid chemical plating, coatings, etc., can solve problems such as stability decline, and achieve the effects of improving stability, improving efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

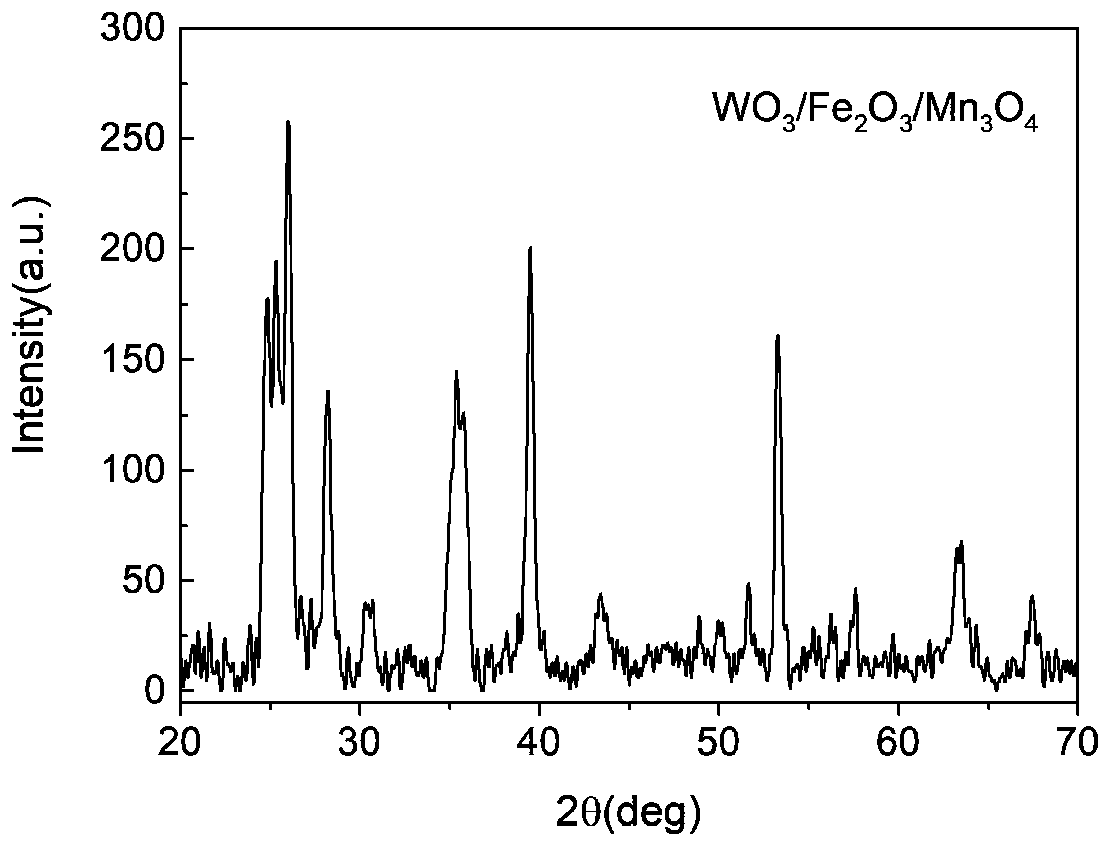

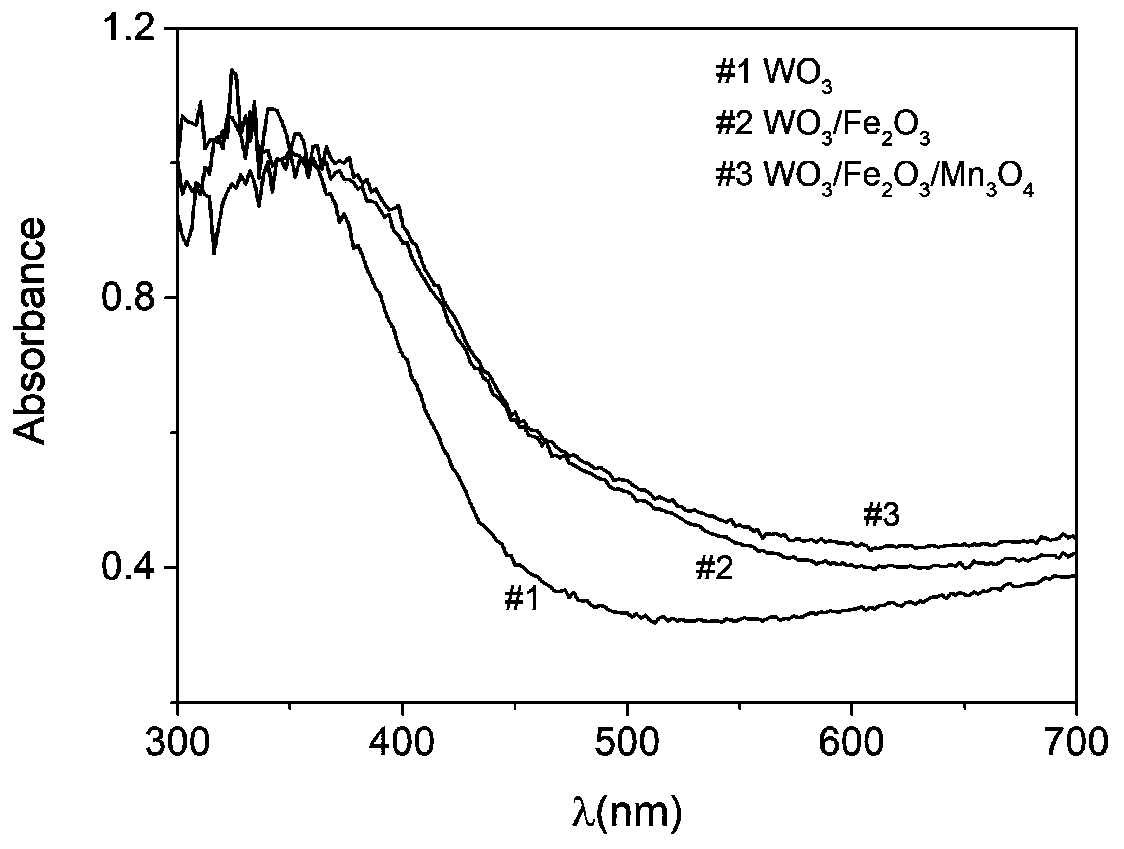

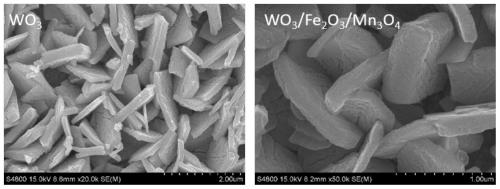

[0017] A kind of WO 3 / Fe 2 o 3 / Mn 3 o 4 The preparation method of composite photoanode film, concrete steps are as follows:

[0018] Dissolve 0.12g sodium tungstate in 15ml aqueous solution, add 1.25ml concentrated hydrochloric acid dropwise; then, dissolve 0.11g ammonium oxalate in 15ml aqueous solution, slowly add to the above sodium tungstate solution, stir for 30min; transfer to 50ml hydrothermal In the reaction kettle, put FTO conductive glass, heat water at 140°C for 6h, cool, wash with water, dry in air, and calcinate at 500°C for 2h to obtain WO 3 Thin film electrode; weigh 0.81g of FeCl 3 , add 50mL of ethanol, stir for 30min, get FeCl 3 Colloidal solution, further to WO 3 Spin-coat 100 μL of the above-mentioned colloid on the film, remove the conductive glass after spin-coating, and dry it at room temperature, then put it in a muffle furnace for calcination at 350°C for 5 minutes, take it out and spin-coat again, repeat the above operation once; weigh 0.88g ...

Embodiment 2

[0021] A kind of WO 3 / Fe 2 o 3 / Mn 3 o 4 The preparation method of composite photoanode film, concrete steps are as follows:

[0022] Dissolve 0.12g sodium tungstate in 15ml aqueous solution, add 1.25ml concentrated hydrochloric acid dropwise; then, dissolve 0.11g ammonium oxalate in 15ml aqueous solution, slowly add to the above sodium tungstate solution, stir for 30min; transfer to 50ml hydrothermal In the reaction kettle, put FTO conductive glass, heat water at 140°C for 6h, cool, wash with water, dry in air, and calcinate at 500°C for 2h to obtain WO 3 Membrane electrode: Weigh 1g of ferric nitrate, add 50mL of ethanol, stir for 30min to obtain ferric nitrate colloidal solution, and add to WO 3 Spin-coat 100 μL of the above-mentioned colloid on the film, remove the conductive glass after spin-coating, and dry it at room temperature, then put it in a muffle furnace for calcination at 350°C for 5 minutes, take it out and spin-coat again, repeat the above operation once...

Embodiment 3

[0025] A kind of WO 3 / Fe 2 o 3 / Mn 3 o 4 The preparation method of composite photoanode film, concrete steps are as follows:

[0026] Dissolve 0.12g sodium tungstate in 15ml aqueous solution, add 1.25ml concentrated hydrochloric acid dropwise; then, dissolve 0.11g ammonium oxalate in 15ml aqueous solution, slowly add to the above sodium tungstate solution, stir for 30min; transfer to 50ml hydrothermal In the reaction kettle, put FTO conductive glass, heat water at 140°C for 6h, cool, wash with water, dry in air, and calcinate at 500°C for 2h to obtain WO 3 Membrane electrode; Weigh the ferric sulfate of 0.6g, add the ethanol of 50mL, stir 30min, obtain ferric sulfate colloidal solution, add to WO 3 Spin-coat 100 μL of the above-mentioned colloid on the film, remove the conductive glass after spin-coating, and dry it at room temperature, then put it in a muffle furnace for calcination at 350°C for 5 minutes, take it out and spin-coat again, repeat the above operation twic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com