Pt-M metal alloy catalyst prepared by electro-deposition in organic system

A metal alloy and catalyst technology, applied in the field of Pt-M metal alloy catalyst and its preparation, can solve the problems of limiting the breakthrough of cathode noble metal catalysts, limited control methods, single synthesis means, etc., and achieve the improvement of comprehensive utilization efficiency and the reduction of platinum loading , The effect of enhanced catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

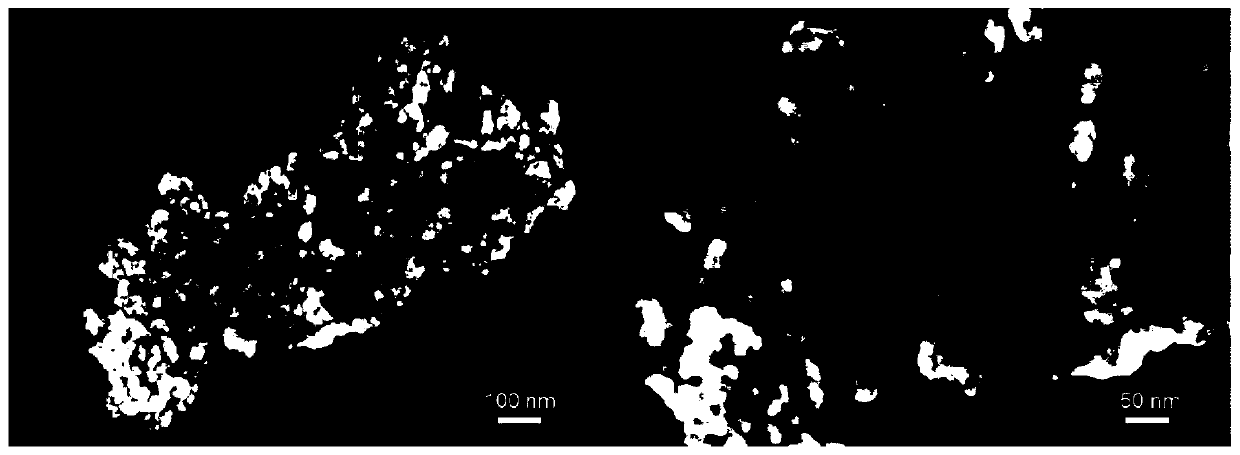

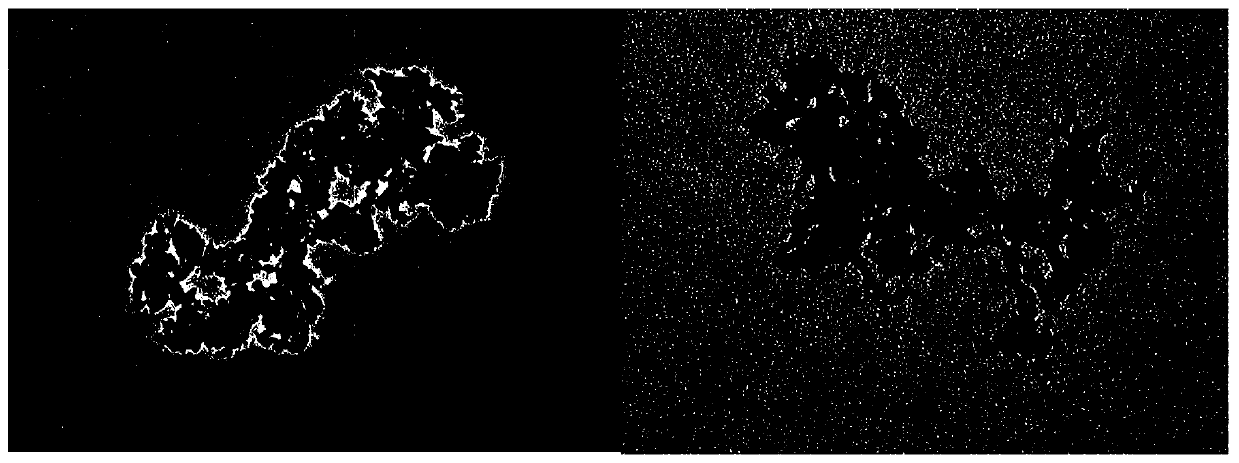

Image

Examples

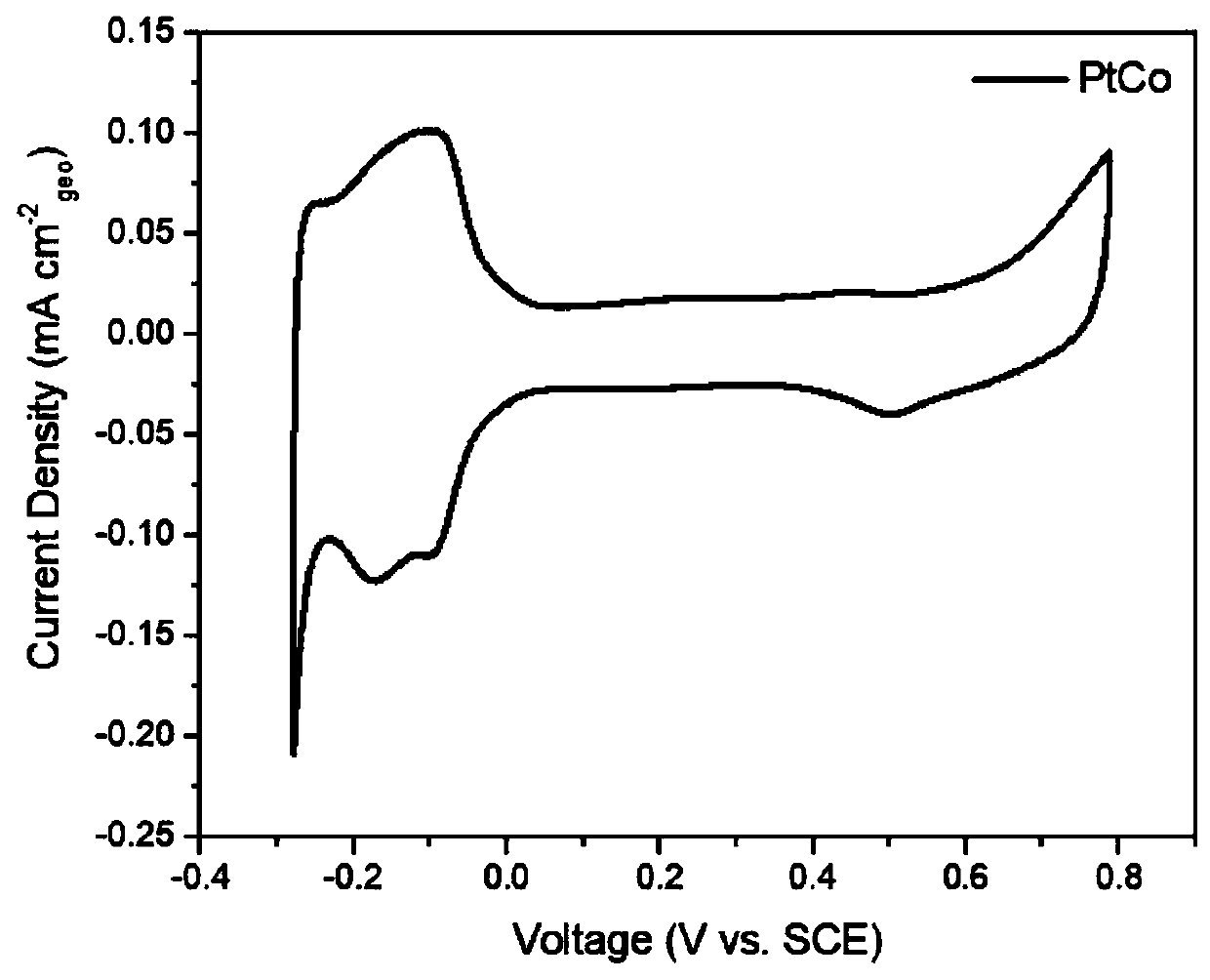

Embodiment 1

[0055] The preparation steps of the Pt-M metal alloy nanoparticle catalyst with high catalytic performance of the present embodiment are as follows:

[0056] 1. Use an electronic balance to weigh the corresponding reagents according to a certain quality. The Pt source is chloroplatinic acid, the M metal source is cobalt acetylacetonate precursor salt, the supporting electrolyte is potassium perchlorate, and the inert gas N 2 , added to a certain amount of organic solvent DMF, stirred and mixed, and fully stirred evenly;

[0057] 2. Add the above mixed liquid to molecular sieve to remove water;

[0058] 3. Ultrasonic the above reaction product for 3 minutes to disperse evenly;

[0059] 4. Connect the electrochemical device, the electrode is deposited at different deposition potentials from -1.5V to -2.2V (vs. SCE); the scan rate is 25mV / s, and cyclic voltammetry electrochemical cleaning is performed between 0.55V.

[0060] 6. Using constant current electrodeposition method, c...

Embodiment 2

[0066] The preparation steps of the Pt-M metal alloy nanoparticle catalyst with high catalytic performance in this embodiment are the same as those in Example 1, except that:

[0067] 1. Use an electronic balance to weigh the reagent according to a certain quality. The Pt source is chloroplatinic acid, the M metal source is nickel acetylacetonate precursor salt, the supporting electrolyte is potassium perchlorate, and the inert gas N 2 , added to a certain amount of organic solvent DMF, stirred and mixed, and fully stirred evenly;

[0068] 2. Add the above mixed liquid to molecular sieve to remove water;

[0069] 3. Ultrasonic the above reaction product for 3 minutes to disperse evenly;

[0070] 4. Connect the electrochemical device, the electrode is deposited at different deposition potentials from -1.5V to -2.2V (vs. SCE); the scan rate is 25mV / s, and cyclic voltammetry electrochemical cleaning is performed between 0.55V.

[0071] 6. Using constant current electrodepositio...

Embodiment 3

[0077] The preparation steps of the Pt-M metal alloy nanoparticle catalyst with high catalytic performance in this embodiment are the same as those in Example 1, except that:

[0078] 1. Use an electronic balance to weigh the reagent according to a certain quality. The Pt source is chloroplatinic acid, the M metal source is nickel acetylacetonate precursor salt, the supporting electrolyte is tetrabutylammonium chloride, and the inert gas N 2 , added to a certain amount of organic solvent DMF, stirred and mixed, and fully stirred evenly;

[0079] 2. Add the above mixed liquid to molecular sieve to remove water;

[0080] 3. Ultrasonic the above reaction product for 0.5 minutes to disperse evenly;

[0081] 4. Double-click the electrochemical device, the electrode is deposited at different deposition potentials from -1.5V to -2.2V (vs. SCE); the scan rate is 5mV / s, and cyclic voltammetry electrochemical cleaning is performed between 0.3V .

[0082] 6. Using constant current ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com