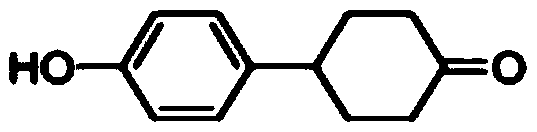

Preparation method of 4-(4-hydroxyphenyl) cyclohexanone

A technology of hydroxyphenyl and cyclohexanone, which is applied in the field of preparation of 4-cyclohexanone, can solve the problems of large environmental pollution, high preparation cost, and low yield, and achieve high safety, low production cost, and high yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

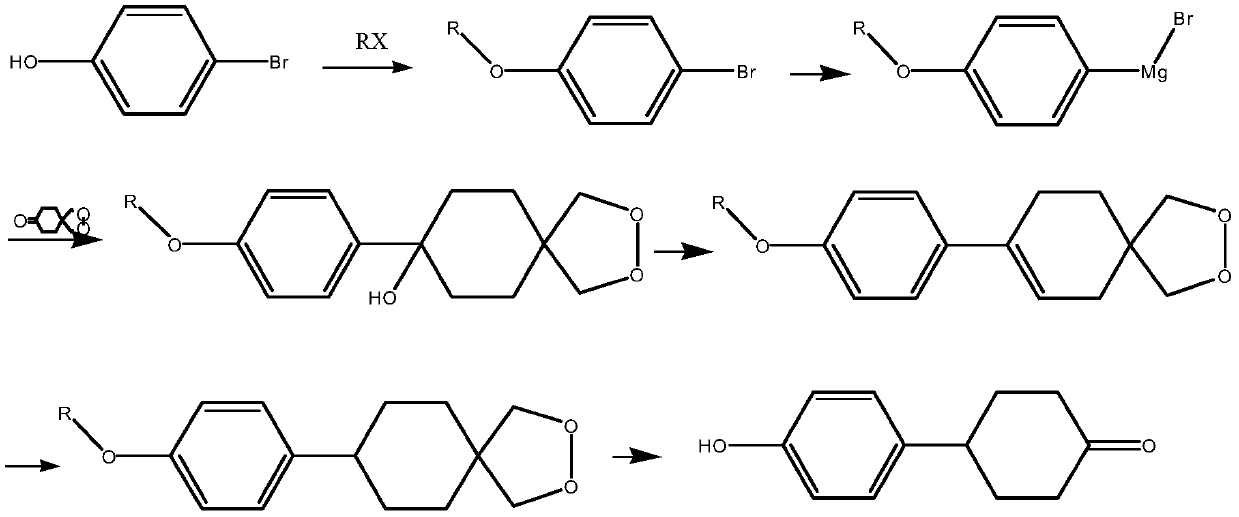

Method used

Image

Examples

Embodiment 1

[0060] A kind of preparation method of 4-(4-hydroxyphenyl) cyclohexanone:

[0061] Step 1. Put 346g of p-bromophenol and 242.9g of triethylamine in a 3000ml three-necked flask, add 1000mL of dichloromethane, stir well, and add the dichloromethane solution of trimethylchlorosilane dropwise in an ice-salt bath at 0°C (250g of trimethylchlorosilane dissolved in 700mL of dichloromethane), the temperature control does not exceed 30°C, after 60 minutes of dropwise addition, a white salt appears in the system, the temperature of the water bath is raised to 30°C, stirred for 3h, and 600ml of water is added to the system, After stirring for 30 minutes, after-treatment, 463.48 g of p-trimethylsilyloxybromobenzene was obtained as a colorless and transparent liquid, with a yield of 94.6% and a purity of 99.3%;

[0062] Step 2. Under the protection of nitrogen, put 8.7g of magnesium chips in a 500mL three-necked flask, and put it in a water bath at 40°C. Dissolve 73.5g of the p-trimethylsi...

Embodiment 2

[0069] A kind of preparation method of 4-(4-hydroxyphenyl) cyclohexanone:

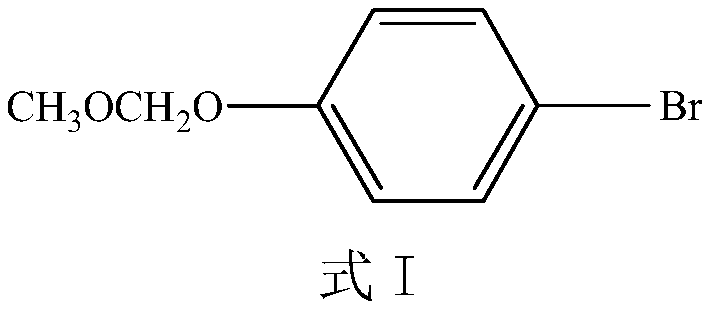

[0070] Step 1. Put 346g of p-bromophenol and 237.3g of pyridine in a 3000ml three-neck flask, add 1038mL of toluene, stir well, and add the toluene solution of methylal dropwise under the condition of ice-salt bath (182.6g of methylal is dissolved in 913mL of toluene middle), temperature control does not exceed 50°C, after 60 minutes of dropwise addition, white salt appears in the system, stir and react at 30°C for 1 hour, add 600ml of water to the system, stir for 30 minutes, post-treatment can get the compound shown in formula I 417.07g of methoxymethoxybromobenzene is a colorless transparent liquid with a yield of 96.1% and a purity of 99.5%;

[0071]

[0072] Step 2. Under the protection of nitrogen, place 7.56g of magnesium chips in a 500mL three-necked flask, and put it in an ice-salt bath at 0°C. Dissolve 65.1g of p-methoxymethoxybromobenzene prepared above in 148mL of ether, and add dropwise...

Embodiment 3

[0079] A kind of preparation method of 4-(4-hydroxyphenyl) cyclohexanone:

[0080] Step 1. Put 346g of p-bromophenol and 424g of sodium carbonate in a 3000ml there-necked flask, add 1730mL of dichloroethane, stir well, and add dropwise the dichloroethane solution of dihydropyran (252.4g Dissolve dihydropyranane in 758mL dichloroethane), control the temperature not to exceed 40°C, after 50min dropwise addition, a white salt appears in the system, stir and react at 30°C for 4h, add 600ml water to the system, stir for 30min , post-processing can obtain 474.72 g of a colorless and transparent liquid of p-bromophenol tetrahydropyranyl ether shown in formula II, with a yield of 91.6% and a purity of 99.4%;

[0081]

[0082] Step 2. Under the protection of nitrogen, put 8.1g of magnesium chips in a 500mL three-necked flask, in a water bath at 30°C, and dissolve 77.4g of p-bromophenol tetrahydropyranyl ether prepared above in 253mL of methyl tert-butyl ether, Add dropwise to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com