Nano silicon dioxide-doped nanocellulose material as well as preparation method and application thereof

A nano-silica and nano-cellulose technology, which is applied in the field of nano-silica doped nano-cellulose materials and their preparation, can solve the problem that nano-cellulose cannot be completely dispersed evenly, does not pay too much attention to the dispersion performance, and increases the energy consumption. It can improve the shortcomings of delayed rubber vulcanization, improve vulcanization efficiency and relieve pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

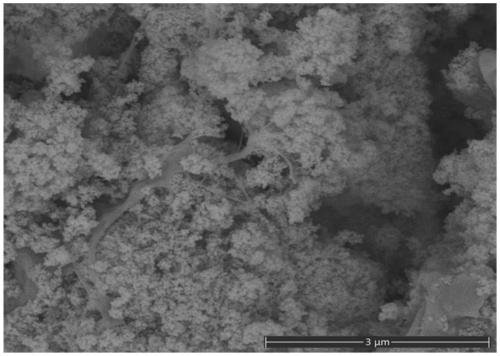

[0077] A nano-silica-doped nano-cellulose material, wherein at least part of the hydrogen bond exists between the nano-silica and the nano-cellulose material, and the mass percentage of the nano-silica is 90%.

[0078] The preparation method is as follows:

[0079] (1) The nanocellulose (average diameter is 10nm, aspect ratio is 100-120) dispersion liquid that concentration is 6% is mixed with the sodium metasilicate solution that concentration is 22% at 78 ℃, 340r / min mixing speed 40min, and then dropwise add a sulfuric acid solution with a concentration of 20wt% until the pH is 8, and the dropping time is 1.5h.

[0080] (2) After stopping the dripping of sulfuric acid solution, age for 2h, keep the stirring speed and temperature of the above conditions in this process, then filter and wash until the conductivity of the filtrate is in the range of 0.1-1.0us / cm and the pH is 7, and finally Spray-drying is carried out at 170° C. to obtain a nano-silicon dioxide-doped nano-cell...

preparation example 2-5

[0083] The difference from Preparation Example 1 is that the concentration of the nanocellulose dispersion is 5% (Preparation Example 2), 8% (Preparation Example 3), 3% (Preparation Example 4), and 10% (Preparation Example 5).

preparation example 6-9

[0085] The difference with Preparation Example 1 is that the concentration of sodium metasilicate solution is 20% (Preparation Example 6), 25% (Preparation Example 7), 15% (Preparation Example 8), 30% (Preparation Example 9).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com