Heavy metal wastewater treatment system and method

A wastewater treatment system and heavy metal technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sewage multi-stage treatment, etc., can solve problems such as difficult wastewater treatment, livestock death, and great harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

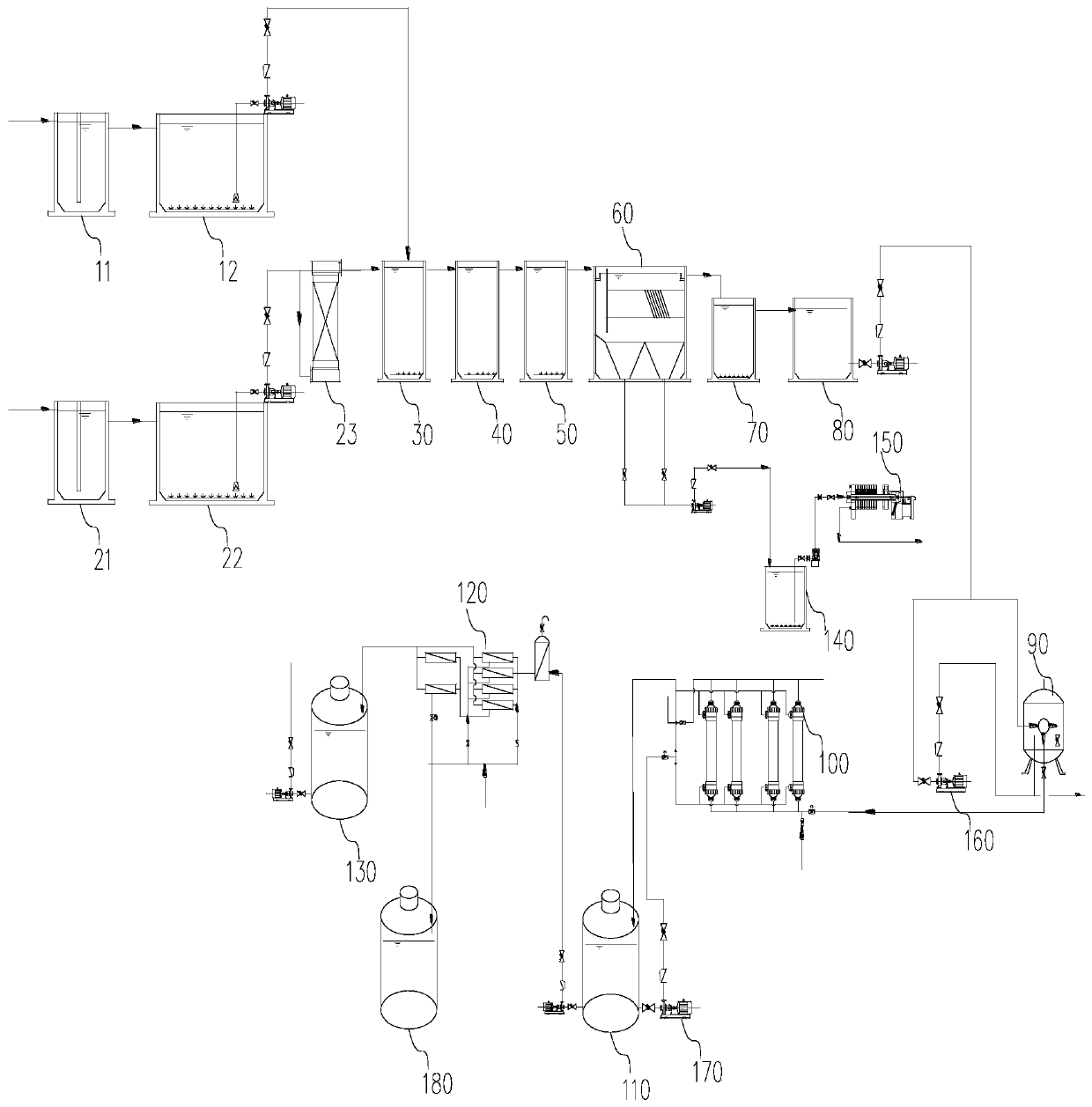

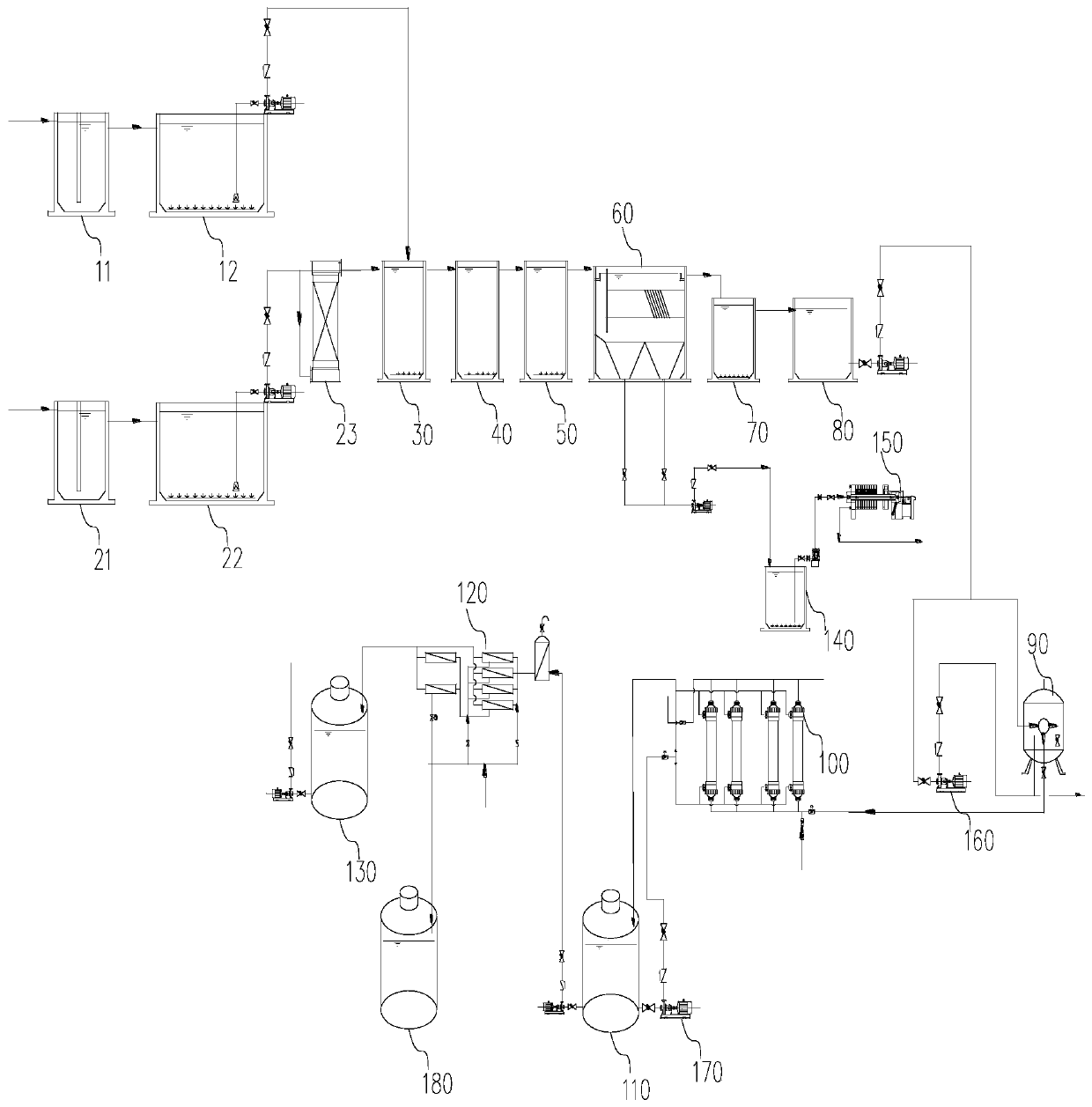

[0053] refer to figure 1 , a heavy metal wastewater treatment system, comprising a pH adjustment tank 30, a coagulation tank 40, a flocculation tank 50, a sedimentation tank 60, a pH callback tank 70, an intermediate pool 80, a multimedia filter 90, and an ultrafiltration system 100 connected in sequence , the first concentrated water tank 110, the reverse osmosis system 120 and the reuse water tank 130; also include the first pretreatment system and the second pretreatment system;

[0054] The first pretreatment system includes a first grease trap 11 and a first regulating pond 12; the water inlet of the first grease trap 11 is connected to the circuit board pre-treatment waste water, and its water outlet is connected to the first regulating pond 12. The water inlet is connected, and the water outlet of the first adjustment tank 12 is connected with the water inlet of the pH adjustment tank 30 through a lift pump;

[0055] The second pretreatment system includes a second gre...

Embodiment 2

[0070] A method for treating heavy metal wastewater, comprising the steps of:

[0071] Build system step: set up a kind of heavy metal wastewater treatment system as described in embodiment 1;

[0072] Pretreatment steps: the pre-treatment wastewater of the circuit board enters the first grease trap for oil-water separation, completes oil removal, and then enters the first regulating tank for buffering to obtain the first pre-treatment wastewater; the post-treatment wastewater of the circuit board enters the second grease trap for After the oil-water separation, oil removal is completed, and then enters the second regulating tank for buffering, and the wastewater in the second regulating tank enters the micro-electrolysis tower for micro-electrolysis reaction treatment to obtain the second pre-treated wastewater;

[0073] Biochemical treatment steps: send the first pretreatment wastewater and the second pretreatment wastewater into the pH adjustment tank respectively, add sodi...

Embodiment 3

[0080] A method for treating heavy metal wastewater, comprising the steps of:

[0081] Build system step: set up a kind of heavy metal wastewater treatment system as described in embodiment 1;

[0082] Pretreatment steps: the pre-treatment wastewater of the circuit board enters the first grease trap for oil-water separation, completes oil removal, and then enters the first regulating tank for buffering to obtain the first pre-treatment wastewater; the post-treatment wastewater of the circuit board enters the second grease trap for After the oil-water separation, oil removal is completed, and then enters the second regulating tank for buffering, and the wastewater in the second regulating tank enters the micro-electrolysis tower for micro-electrolysis reaction treatment to obtain the second pre-treated wastewater;

[0083] Biochemical treatment steps: send the first pretreatment wastewater and the second pretreatment wastewater into the pH adjustment tank respectively, add sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com