A method for promoting the dispersion and migration of nano ferric oxide

A ferric tetroxide and nanotechnology, applied in the field of environmental engineering, can solve the problems of easy deposition and adhesion on the surface of soil particles or trapped in the voids of soil particles, increased potential barrier, poor mobility, etc., and achieves remarkable migration performance. , Improve migration performance, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Weigh 0.5g xanthan gum (referred to as: XG) powder dissolve in 250 ml simulated groundwater (referred to as: AGW), stir evenly, and dispersed. The xanthan gum solution having a mass concentration of 2 g / L was obtained.

[0038] 2) Weigh 0.005 g, 0.05 g of nano-tetraned iron (referred to as: MNPS) powder, add to 250 ml of xanthan glue solution, stir even, and XG-MNPS suspension is obtained. The mass concentration of MNPS powder in suspension is 0.02 g / L, 0.2 g / L, respectively.

[0039] 3) Weigh 0.005 g, 0.05 g of MNPS powder, add to 250 ml of AGW solution, stir well, and MNPS suspension is produced. The mass concentration of MNPS powder in suspension is 0.02 g / L, 0.2 g / L, respectively.

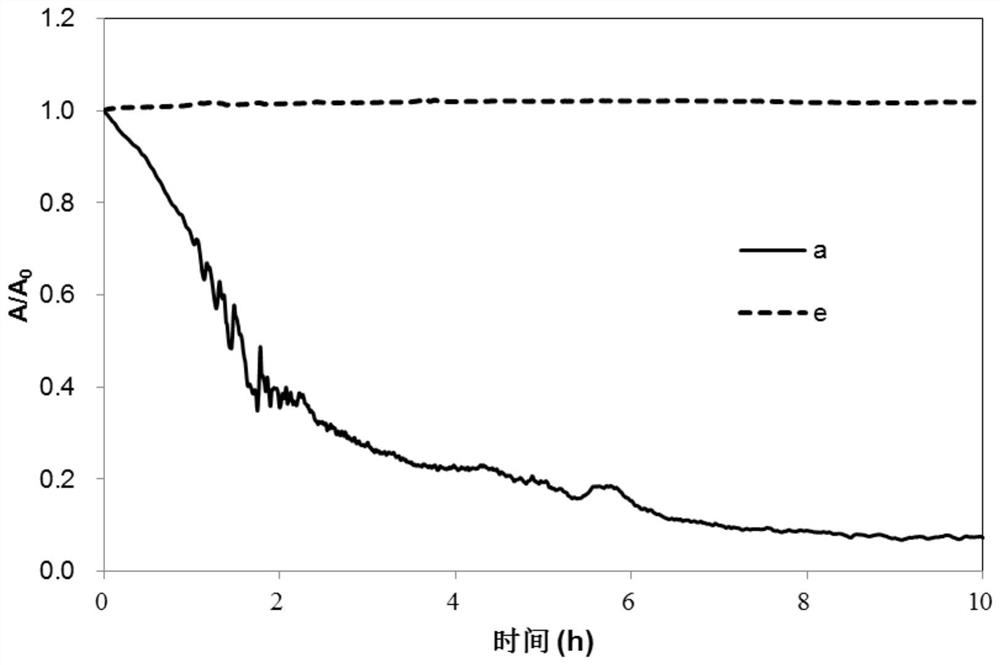

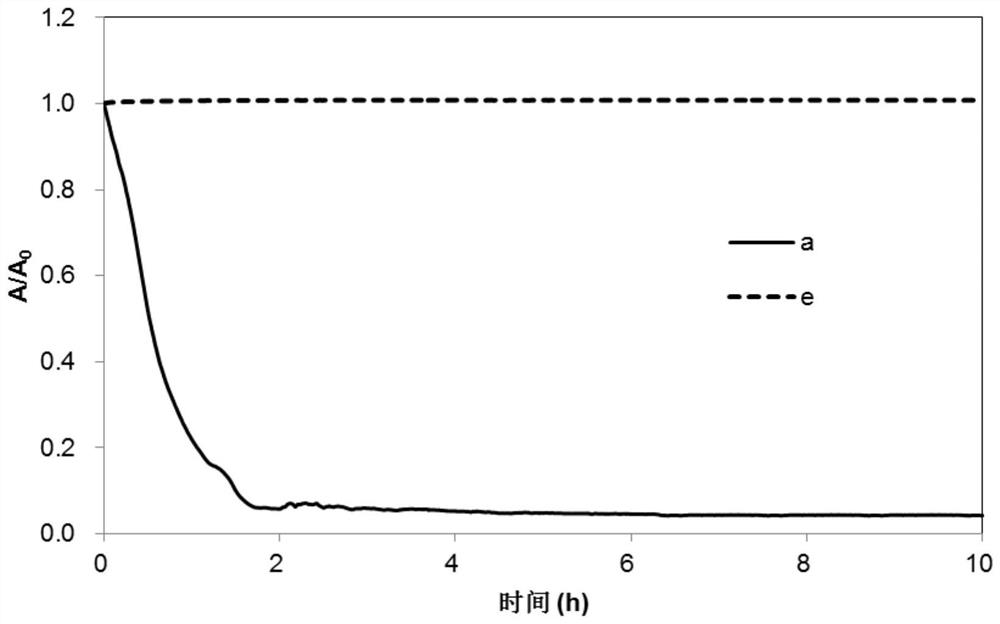

[0040]4) When the MNPS suspension or XG-mNPS suspension is completed, settled dynamic experiments immediately, using an ultraviolet spectrophotometer, measurement of the absorbance over time at a wavelength of 720 nm, and draw relative absorbance (different The ratio of the abso...

Embodiment 2

[0044] 1) Weigh 0.5g xanthan gum (referred to as: XG) powder dissolve in 250 ml simulated groundwater (referred to as: AGW), stir evenly, and dispersed. The xanthan gum solution having a mass concentration of 2 g / L was obtained.

[0045] 2) Weigh 0.5 g, 1.0 g, 2.0 g, 3.0 g, 4.0 g, 5.0 g of nano-tetra-dioxide (referred to as: MNPS) powder, added to 250 ml of xanthan glue solution, stir well, to prepare XG-MNPS Suspension. In the suspension, the MNPs powder mass concentration was 2 g / l, 4 g / l, 8 g / l, 12 g / l, 16 g / l, 20 g / L.

[0046] 3) When the XG-MNPS suspension is completed, the settling dynamics experiment is performed immediately, and the suspension is transferred to 250 mL of the cylinder, and then sampled, sampled, sampled, and hydrochloric acid at the distance of 6cm from the liquid surface. After digestion, after MNPS is completely disinplanted, remove 1ml of solution, add acetate buffer solution to adjust the pH to 3 to 5, stand for 10 minutes, and then use th...

Embodiment 3

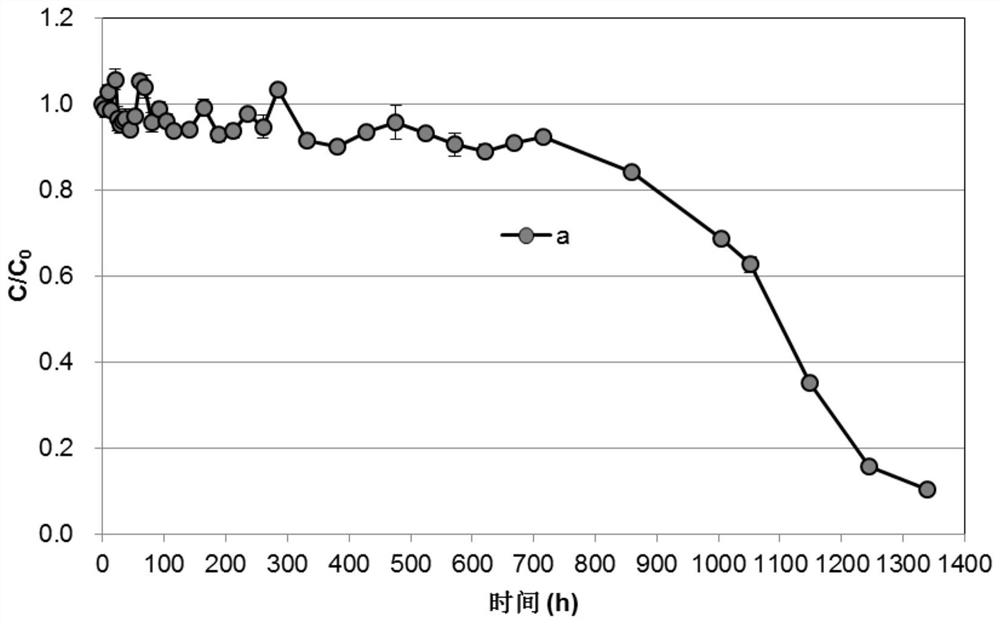

[0053] 1) In a glass stainless steel column of 2 cm, the length is 15 cm, and the natural quartz sand porous medium is uniformly filled, and the carbon dioxide gas is introduced into the quartz sand column to remove air. The AGW solution obtained from the bottom of the quartz sand column was performed from the bottom end of the quartz sand column until the sand column was saturated from the bottom end of the quartz sand column (the column remains constant).

[0054] 2) Weigh 0.5g xanthan adhesive (referred to as: XG) powder dissolved in 250 ml to simulate groundwater (referred to as: AGW), stir evenly, and dispersed. The xanthan gum solution having a mass concentration of 2 g / L was obtained.

[0055] 3) Weigh 0.25 g, 0.5 g, 1.0 g, 2.0 g of nano-tetraned oxide (referred to as: mnps) powder, add to 250 ml of xanthan glue solution, stir well, and XG-MNPS suspension is obtained. The MNPS powder mass concentration was 1 g / l, 2 g / l, 4g / l, 8 g / L, respectively.

[0056] 4) Weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com