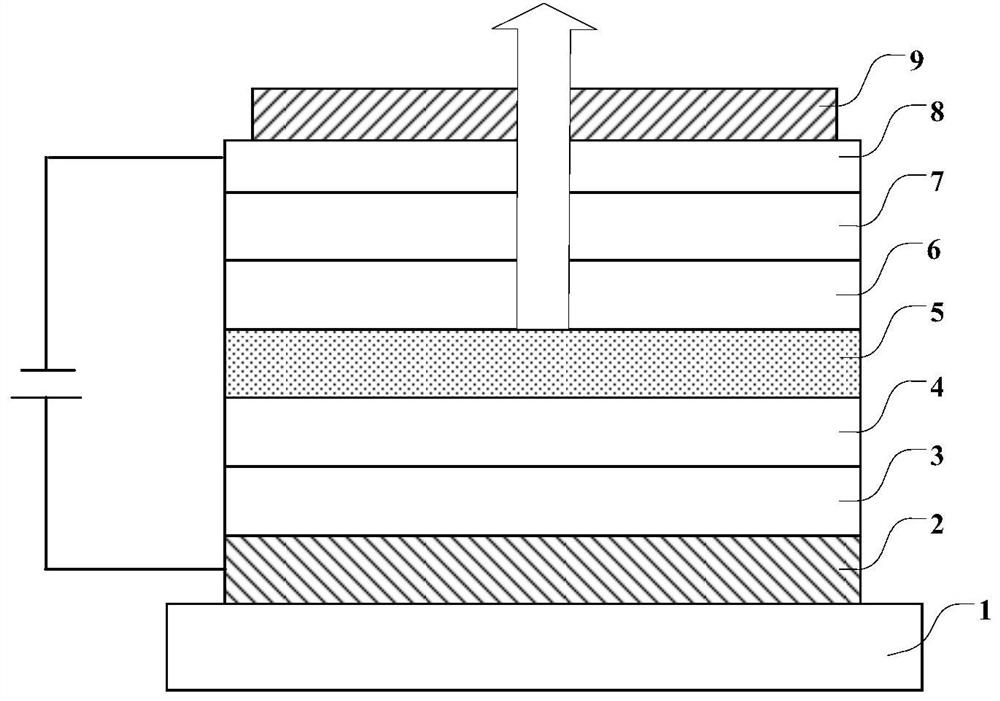

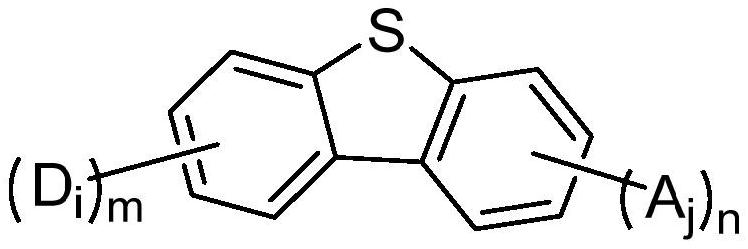

Compound, luminescent material, organic light-emitting display panel, and organic light-emitting display device

A technology for luminescent display and luminescent materials, which is applied in the fields of compounds, luminescent materials, organic light-emitting display panels and organic light-emitting display devices. Effect of improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0125] Compound P1 was prepared by the following method:

[0126] Specific steps:

[0127]

[0128] Weigh S1 (8.0mmol), S2 (9.7mmol), K2CO3 (33.9mmol), CuI (2.0mmol), 18-crown-6 (0.82mmol), and dissolve in anhydrous dichlorobenzene under nitrogen atmosphere. Stir at 100°C for 12h. After the reaction, cool to room temperature. Extract with dichloromethane, collect the organic phase, and wash with anhydrous Na 2 SO 4 Dry processing. The dried solution was filtered, and the solvent was removed by a rotary evaporator to obtain a crude product. The crude product was purified by silica gel column chromatography, and the final purification gave solid S3 (4.8 mmol, 60%).

[0129] Characterization results: MALDI-TOF MS: m / z calcd for C 24 h 14 BrNS: 427.0; found: 427.3.

[0130]

[0131] At -78°C, S3 (2.0 mmol) was dissolved in ether (40 mL), and nBuLi (3.0 mmol) in n-hexane was added dropwise to the solution. The reaction solution was continuously stirred for 2 h, slow...

preparation example 2

[0134] Compound P3 was prepared by the following method:

[0135]

[0136] Specific steps:

[0137] Weigh S1 (6mmol), S5 (7.2mmol), K 2 CO 3 (25.2mmol), CuI (1.5mmol), 18-crown-6 (0.64mmol), dissolved in anhydrous dichlorobenzene under nitrogen atmosphere. Stir at 100°C for 12h. After the reaction, cool to room temperature. Extract with dichloromethane, collect the organic phase, and wash with anhydrous Na 2 SO 4 Dry processing. The dried solution was filtered, and the solvent was removed by a rotary evaporator to obtain a crude product. The crude product was purified by silica gel column chromatography, and the final purification afforded solid S6 (3.72 mmol, 62%).

[0138] Characterization results: MALDI-TOF MS: m / z calcd for C 27 h 20 BrNS: 469.0; found: 469.4.

[0139]

[0140] At -78°C, S6 (1.5 mmol) was dissolved in ether (40 mL), and nBuLi (2.2 mmol) in n-hexane was added dropwise to the solution. The reaction solution was continuously stirred for 2 h,...

preparation example 3

[0143] Compound P16 was prepared by the following method:

[0144]

[0145] In a 100mL three-necked flask, first S6 (10.0mmol), pinacol diborate (10.5mmol), (1,1,-bis(diphenylphosphino)ferrocene)dichloropalladium(II) (0.2 mmol) and potassium acetate (25.0 mmol) were added respectively, while stirring, degassing and nitrogen replacement were repeated 3 times rapidly, and 50 mL of tetrahydrofuran was added through a syringe. Stir at a certain speed, and heat the reactants of the obtained mixed solution to reflux at a reaction temperature of 80°C for 5 hours; after the reaction is completed, cool to room temperature and add 60 mL of water, extract with ether, and dry the obtained organic phase with anhydrous sodium sulfate , the solvent was distilled off, and purified by column chromatography to obtain intermediate S7 (7.7 mmol, 77%).

[0146] Characterization results: MALDI-TOF MS: m / z calcd for C 33 h 32 BNO 2 S: 517.2; found: 517.3;

[0147]

[0148] Under nitrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com