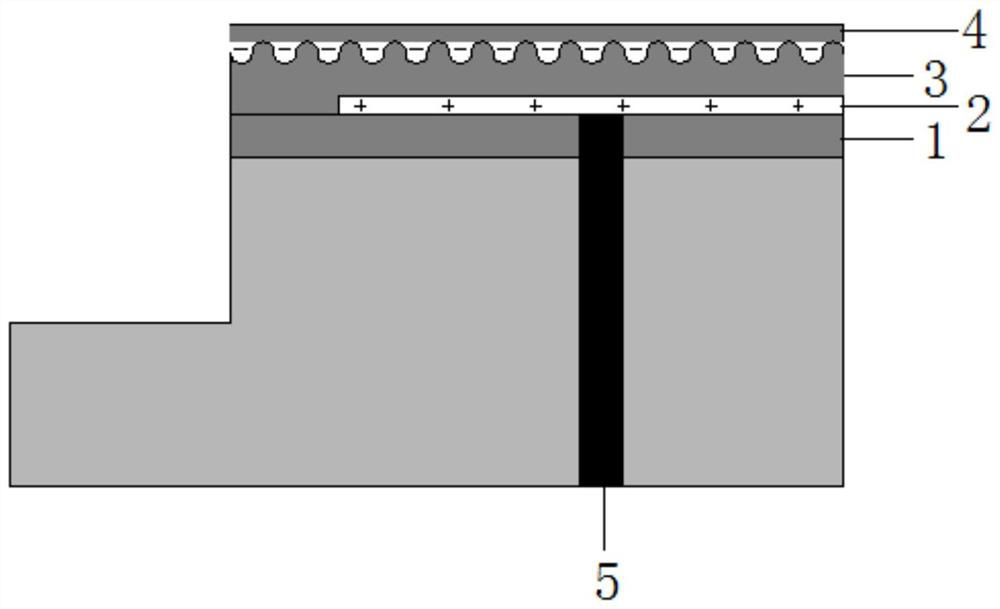

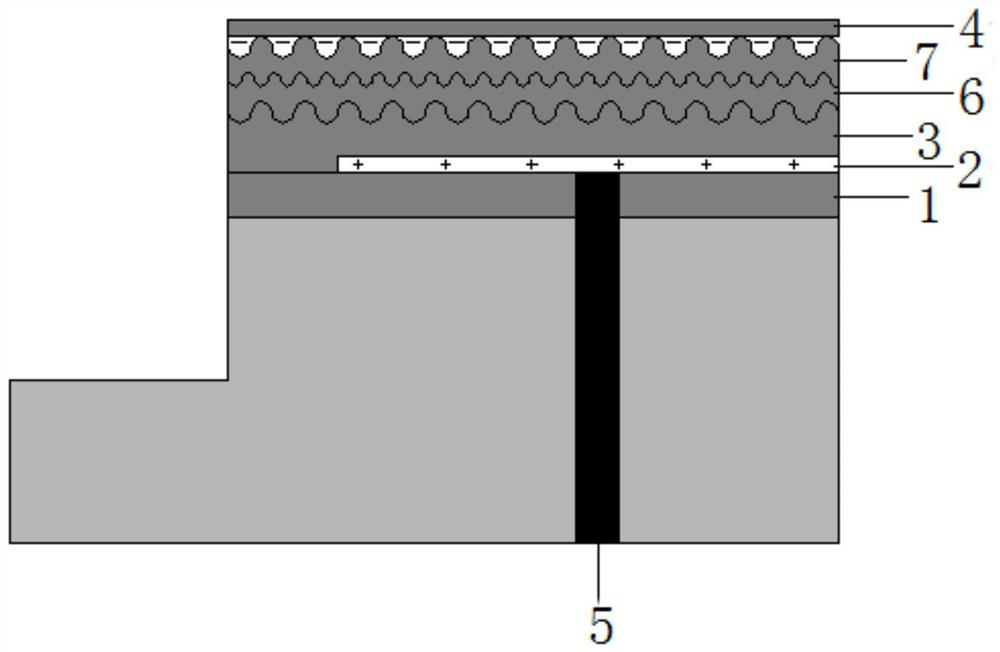

Structure and process method for preventing back scratching of glass substrate on dry-etched electrode surface

A glass substrate and electrode surface technology, which is applied to the coating process of metal materials, circuits, discharge tubes, etc., can solve problems such as glass scratches, pits, and product scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A process method for preventing the surface of the glass substrate surface of the dried electrode surface, the specific steps are as follows:

[0041] Step 1, cleaning drying: Wash the electrode using high pressure water, the deionized water resistance of the high pressure water is greater than 4mΩ * cm, the pressure is 100 bar, then the lower electrode surface is blown dry, and finally 60 ° C in the oven 24h.

[0042] Step 2, plasma spraying dense layers: Plasma spraying is Y 2 O 3 Alone 2 O 3 Composite powder, where Y 2 O 3 The content is at 80% (wt.), Plasma spraying, using a six-axis robot, the spray process parameter is: the main gas Ar flow 40L / min, the secondary h 2 The flow rate is 10 l / min, the voltage 36V, current 800a, and the amount of powder powder are 10 g / min, the spray distance is 100 mm, the thickness of the spray layer reaches 10 μm, and the bonding force reaches 10 MPa.

[0043] Step three, plasma spray top contact layer: Plasma spraying is Y 2 O 3 ...

Embodiment 2

[0048] A process method for preventing the surface of the glass substrate surface of the dried electrode surface, the specific steps are as follows:

[0049] Step 1, cleaning drying: Wash the electrode using high pressure water, the deionized water resistance rate of high pressure water is greater than 4mΩ * cm, the pressure is 150 bar, then the lower electrode surface is blown dry, and finally 80 ° C in the oven 12h.

[0050] Step 2, plasma spraying dense layers: Plasma spraying is Y 2 O 3 Alone 2 O 3 Composite powder, where Y 2 O 3 The content is 85% (wt.), Plasma spraying, using a six-axis robot, the spray process parameter is: the main gas Ar flow 60L / min, the secondary h 2 The flow rate is 15 l / min, the voltage is 40V, the current 900A, the amount of powder powder is 18 g / min, the spray distance is 150 mm, the spray coating has a thickness of 20 μm, and the bonding force reaches 10 MPa.

[0051] Step three, plasma spray top contact layer: Plasma spraying is Y 2 O 3 Alon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com