Coal-based battery negative electrode material and preparation method and application thereof

A battery negative electrode, coal-based technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of difficult combination of particulate matter, low organic matter content, low material capacity, etc., and achieve good sodium storage characteristics and low heat treatment temperature , the effect of high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

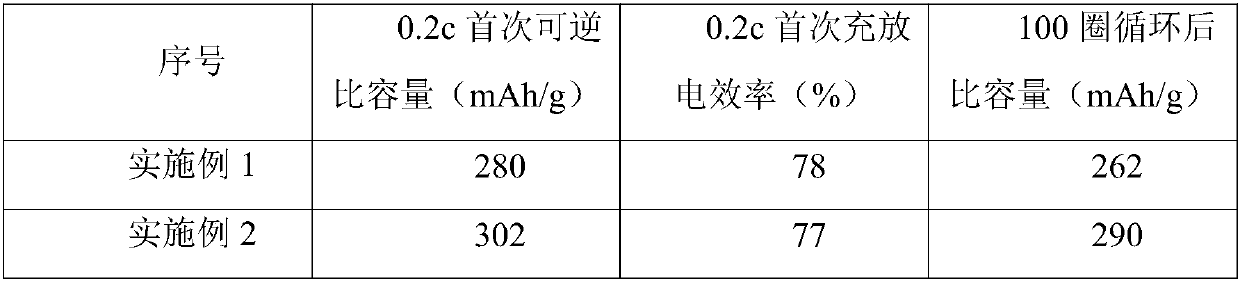

Embodiment 1

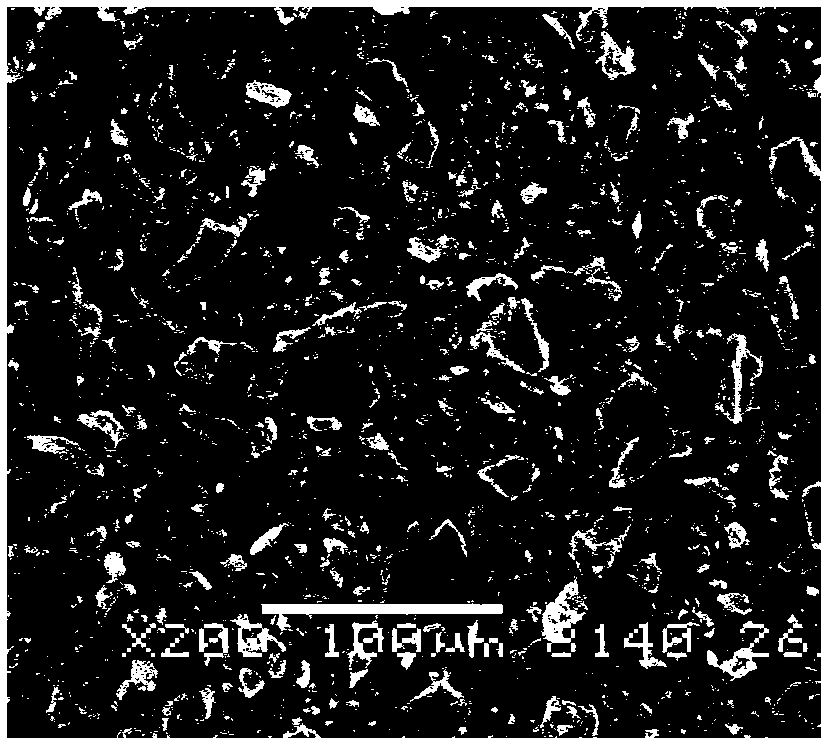

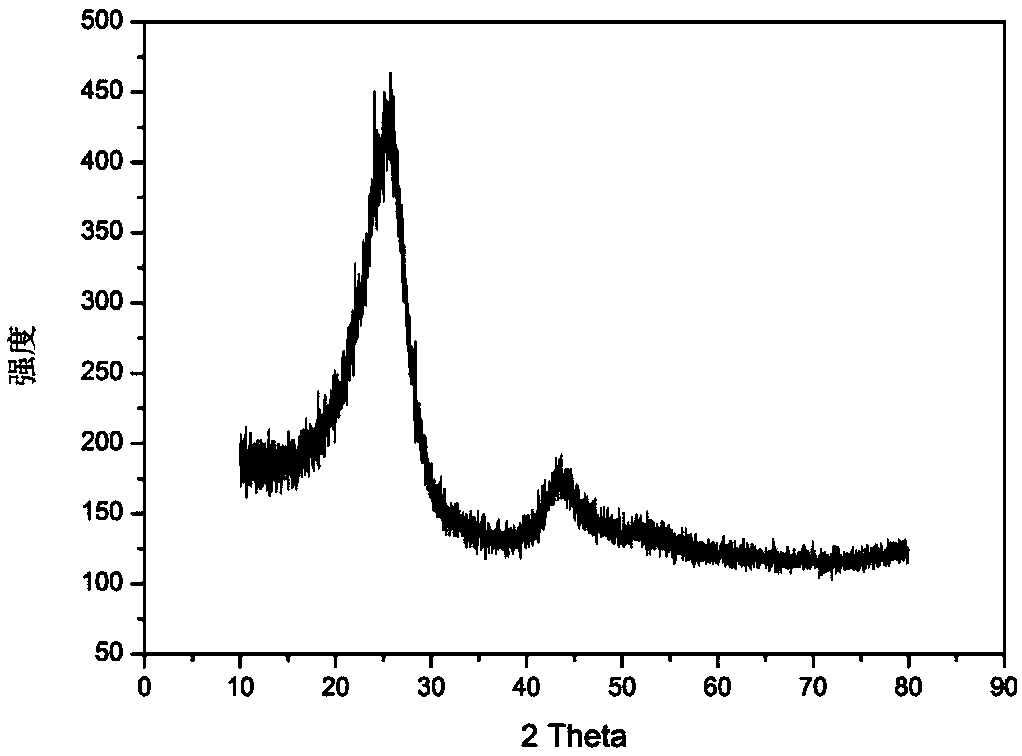

[0070] (1) Select coking coal with a volatile content of 15% in the ash-free base, a cohesive index of 65%, a maximum thickness of the colloidal layer of 25%, and a total heteroatom N, P, S and heteroatom content of 5%. As a raw material, 100 g of coking coal raw material dried at 120°C for 12 hours was put into a vibratory pulverizer for crushing for 2 minutes, then ball-milled for 6 hours in a planetary ball mill, sieved with a 325-mesh sieve, and the undersize was taken.

[0071] (2) Add 50 g of dried, crushed and sieved coking coal into a mixed acid solution with a mass ratio of hydrofluoric acid and sulfuric acid of 10:1, the liquid-solid ratio is 3, and the total acid concentration is adjusted to a pH value of 3. The mixture was stirred and reacted for 2 hours, filtered and washed until neutral to obtain coke purified by acid method, and the ash content of the purified coke was 0.4%.

[0072] (3) Get 2g of purified coking coal and 1g of graphene and carbon nanotube mixtu...

Embodiment 2

[0075] (1) Select the coking coal with a volatile content of 20% in the ash-free base, a cohesive index of 70%, a maximum thickness of the colloidal layer of 25%, and a total heteroatom N, P, S and heteroatom content of 10%. As a raw material, 100 g of coking coal raw material dried at 105°C for 12 hours was put into a vibrating pulverizer for crushing for 5 minutes, then ball milled in a planetary ball mill for 10 hours, sieved with a 325-mesh sieve, and the undersize was taken.

[0076] (2) Add 50 g of dried, crushed, and sieved coking coal into a mixed acid solution with a mass ratio of hydrofluoric acid and sulfuric acid of 10:1, the liquid-solid ratio is 5, and the total acid concentration is adjusted to a pH value of 4 at room temperature. The mixture was stirred and reacted for 5 hours, filtered and washed until neutral to obtain coke purified by acid method, and the ash content of the purified coke was 0.3%.

[0077] (3) Get 40g of purified coking coal and 1g of graphe...

Embodiment 3

[0080] (1) Select coking coal with ash-free base volatile content of 25%, cohesive index of 80%, maximum thickness of colloidal layer of 20%, heteroatoms N, P, S and total heteroatom content of 8%. As a raw material, put 100 g of coking coal raw material dried at 120° C. for 10 h into a vibratory pulverizer for crushing for 2 min, then ball mill for 6 h in a planetary ball mill, and sieve with a 325-mesh sieve to obtain the undersize.

[0081] (2) Add 50 g of dried, crushed and sieved coking coal into a mixed acid solution with a mass ratio of hydrofluoric acid and sulfuric acid of 8:1, the liquid-solid ratio is 4, and the total acid concentration is adjusted to a pH value of 3 at room temperature. The mixture was stirred and reacted for 4 hours, filtered and washed until neutral to obtain acid-purified coke, and the ash content of the purified coke was 0.4%.

[0082] (3) Get 40g of purified coking coal and 4g graphene and carbon nanosphere mixture (the mass ratio of graphene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com