Two-dimensional material solid lubricating film and preparation method thereof

A two-dimensional material, solid lubrication technology, applied in electrolytic inorganic material coating, device for coating liquid on surface, special surface, etc., can solve the problems of poor film compactness, material waste, etc., to improve mechanical properties, improve lubrication performance , the effect of excellent apparent quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Add 1 g of molybdenum disulfide with an average particle size of 5 nm into 100 mL of acetone, and ultrasonicate for 120 h at an ultrasonic power of 50 W. Take 5 mL of the ultrasonic sample and drop-coat it on the bearing steel workpiece, and completely evaporate the solvent by heating and drying at 100°C. Repeat the above steps 5 times, and then spray 1 mL of N,N dimethylformamide (DMF) on the surface of the film , let it dry naturally, and finally undergo vacuum thermal annealing treatment at 200 degrees for 1 hour, and you can get a molybdenum disulfide solid lubricating film with a thickness of about 100 μm.

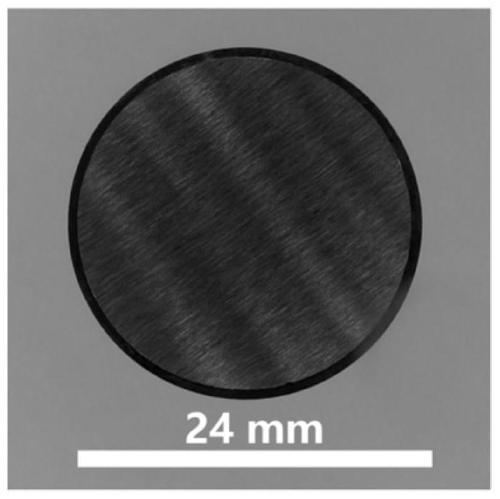

[0060] Figure 1a It is the disc bearing steel workpiece photo in embodiment 1;

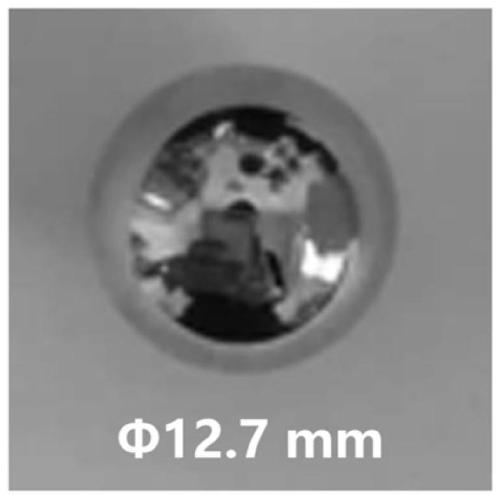

[0061] Figure 1b Be the ball bearing steel workpiece photo in embodiment 1;

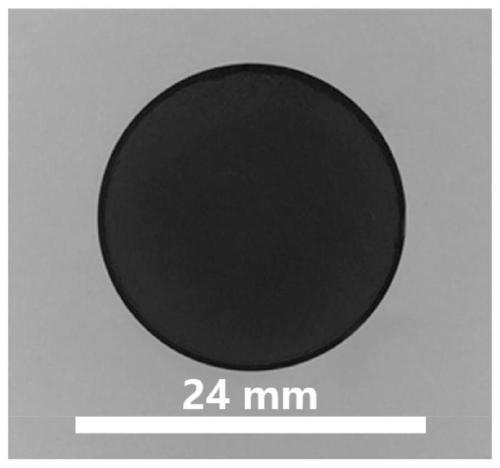

[0062] Figure 2a Be coated with the photo of molybdenum disulfide solid lubricating thin film disc bearing steel workpiece that embodiment 1 obtains;

[0063] Figure 2b Be coated with the photo o...

Embodiment 2

[0067] Add 1 g of boron nitride with an average particle size of 400 nm into 100 mL of isopropanol, and sonicate for 100 h at an ultrasonic power of 250 W. Take 5mL of the ultrasonic sample and spray it on the bearing steel workpiece, and completely evaporate the solvent by heating and drying at 250°C, repeat the above steps 5 times, and finally undergo vacuum thermal annealing treatment at 200°C for 1 hour, and the surface of the bearing steel workpiece can be obtained Boron nitride solid lubricating film with a thickness of about 100 μm.

[0068] Figure 4a Be coated with the photo of the boron nitride solid lubricating film disc bearing steel workpiece obtained in embodiment 2;

[0069] Figure 4b It is the photo of the boron nitride solid lubricating film ball bearing steel workpiece coated with the obtained embodiment 2.

[0070] from Figure 4a with Figure 4b It can be seen that the boron nitride solid lubricating film can be prepared on the surface of the disc (flat...

Embodiment 3

[0072] 1 g of graphene with an average particle size of 100 nm was added to 100 mL of N-methylpyrrolidone (NMP), and ultrasonicated at 250 W for 100 h. Take 5mL of the ultrasonic sample and spray it on the bearing steel workpiece, and completely evaporate the solvent by heating and drying at 250°C, repeat the above steps 10 times, and finally undergo vacuum thermal annealing treatment at 200°C for 1 hour, and the surface of the bearing steel workpiece can be obtained A graphene solid lubricant film with a thickness of about 200 μm.

[0073] Figure 5a Be coated with the photo of graphene solid lubricating film disc bearing steel workpiece that embodiment 3 obtains;

[0074] Figure 5b The photo that is coated with the graphene solid lubricating film ball bearing steel workpiece that embodiment 3 obtains.

[0075] from Figure 5a with Figure 5b It can be seen that the graphene solid lubricating film can be prepared on the surface of the disc (flat surface) and spherical (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com