Preparation method of polyphosphoester

A technology of polyphosphate and phosphorus oxychloride, which is applied in the field of polyphosphate preparation, can solve problems such as the method of reducing the formation of acid phosphate, and achieve the effects of low toxicity, lower production costs, and less side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

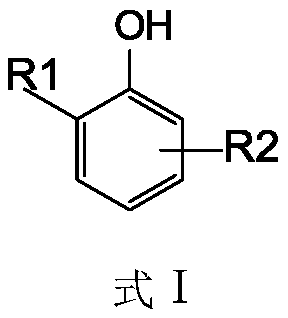

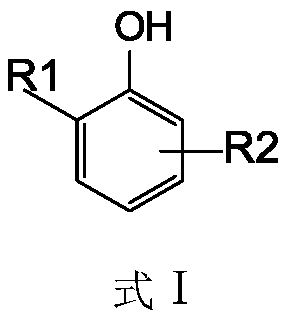

[0031] Embodiment 1, a kind of preparation method of polyphosphate: obtain polyphosphate by one-step method of phosphorus oxychloride, dialkylphenol and hydroquinone, end-capping by phenol at last; The general formula of dialkylphenol is as formula I show:

[0032]

[0033] In formula I: the R 1 , R 2 selected from 2,3-dialkylphenol, 2,4-dialkylphenol, 2,5-dialkylphenol or 2,6-dialkylphenol.

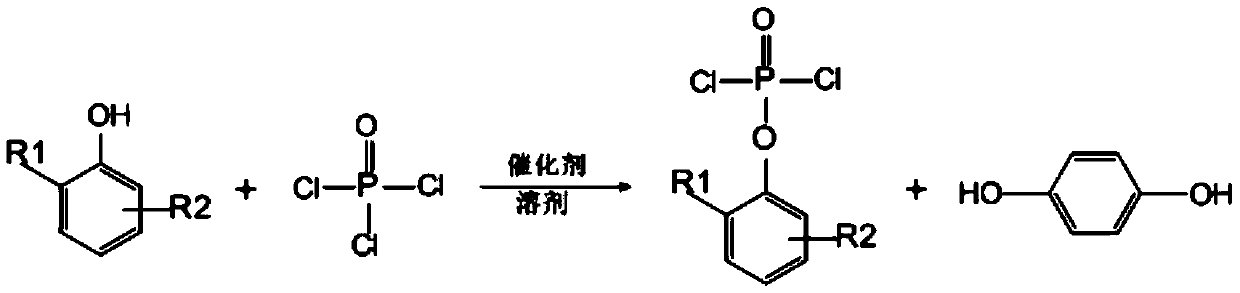

[0034] The method first generates monomeric monophenyl ester from phosphorus oxychloride and dialkylphenol, then polymerizes hydroquinone to obtain a polyphospholipid intermediate, and then caps it with phenol; the degree of polymerization is 1-20; phosphorus oxychloride The molar ratio of dialkylphenol to dialkylphenol is 0.5:1; the molar ratio of hydroquinone to phosphorus oxychloride is 0.8:1.

[0035] The catalyst used in the reaction is AlCl 3 , the consumption of catalyst is 0.05% of dialkylphenol mass. The solvent used in the reaction is carbon tetrachloride. The solvent ...

Embodiment 2

[0036] Embodiment 2, a kind of preparation method of polyphosphate: obtain polyphosphate by one-step method of phosphorus oxychloride, dialkylphenol and hydroquinone, end-capping by phenol at last; The general formula of dialkylphenol is as formula I show:

[0037]

[0038] In formula I: R 1 , R 2 for the same or different linear C 1 -C 5 -alkyl.

[0039] The R 1 , R 2selected from 2,3-dialkylphenol, 2,4-dialkylphenol, 2,5-dialkylphenol or 2,6-dialkylphenol.

[0040] The method first generates monomeric monophenyl ester from phosphorus oxychloride and dialkylphenol, then polymerizes hydroquinone to obtain a polyphospholipid intermediate, and then caps it with phenol; the degree of polymerization is 1-20; phosphorus oxychloride The molar ratio of dialkylphenol to dialkylphenol is 1.5:1; the molar ratio of hydroquinone to phosphorus oxychloride is 5:1.

[0041] The catalyst used in the reaction is MgCl 2 . The amount of catalyst used is 1% of the mass of dialkylphen...

Embodiment 3

[0042] Embodiment 3, a kind of preparation method of polyphosphate: obtain polyphosphate by one-step method of phosphorus oxychloride, dialkylphenol and hydroquinone, end-capping by phenol at last; The general formula of dialkylphenol is as formula I show:

[0043]

[0044] In formula I: R 1 , R 2 for the same or different linear C 1 -C 5 -alkyl.

[0045] The R 1 , R 2 selected from 2,3-dialkylphenol, 2,4-dialkylphenol, 2,5-dialkylphenol or 2,6-dialkylphenol.

[0046] The method first generates monomer monophenyl ester from phosphorus oxychloride and dialkylphenol, then polymerizes polyphospholipid intermediate by hydroquinone, and then caps it with phenol; the degree of polymerization is 15; phosphorus oxychloride and dialkylphenol The molar ratio of alkylphenol is 1:1; the molar ratio of hydroquinone and phosphorus oxychloride is 2:1.

[0047] The catalyst used in the reaction is a Lewis acid catalyst. Described Lewis acid catalyst is ZnCl 2 . The amount of cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com