Crosslinked Modified Polyethyleneimine Solid Electrolyte and Its Application

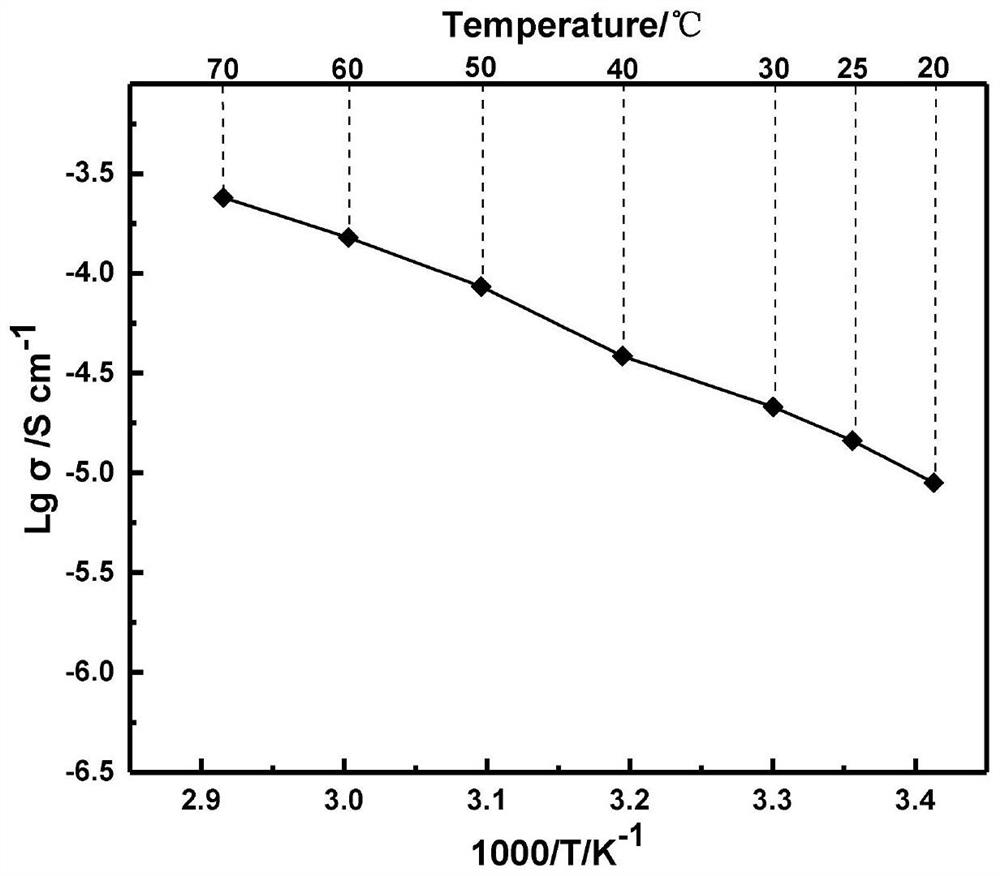

A polyethyleneimine, solid electrolyte technology, applied in solid electrolytes, composite electrolytes, non-aqueous electrolytes, etc., can solve the problems of poor thermal stability, poor film formation, low electrical conductivity, etc., to improve energy density, improve film formation. The effect of reducing the internal resistance of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

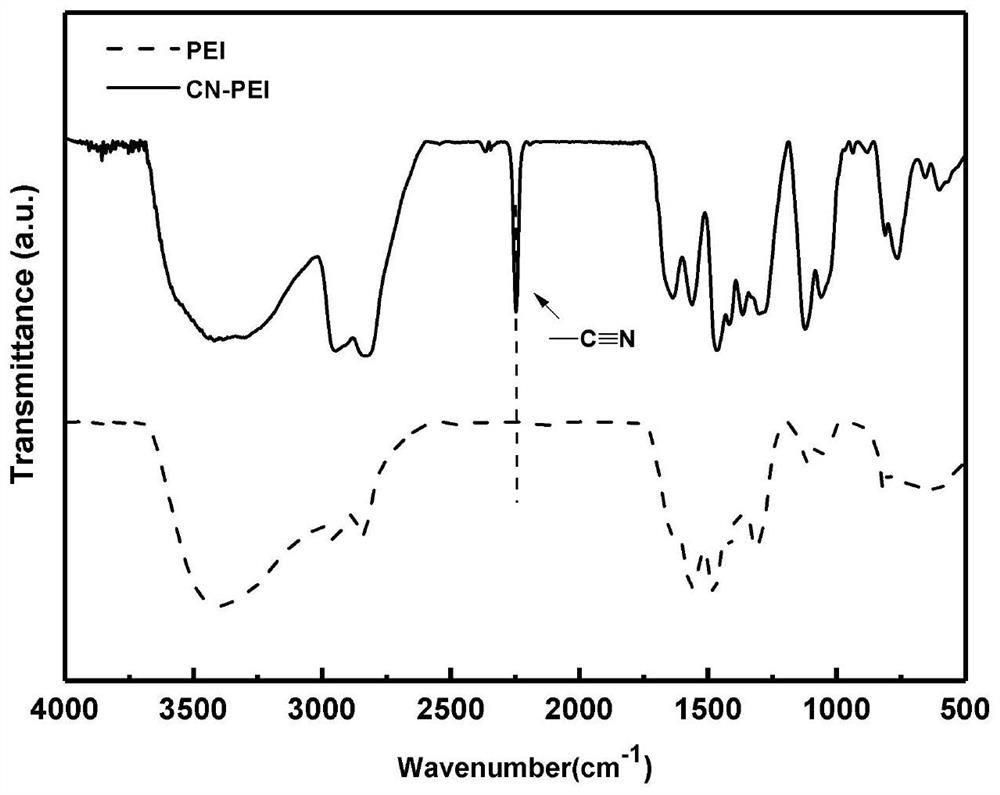

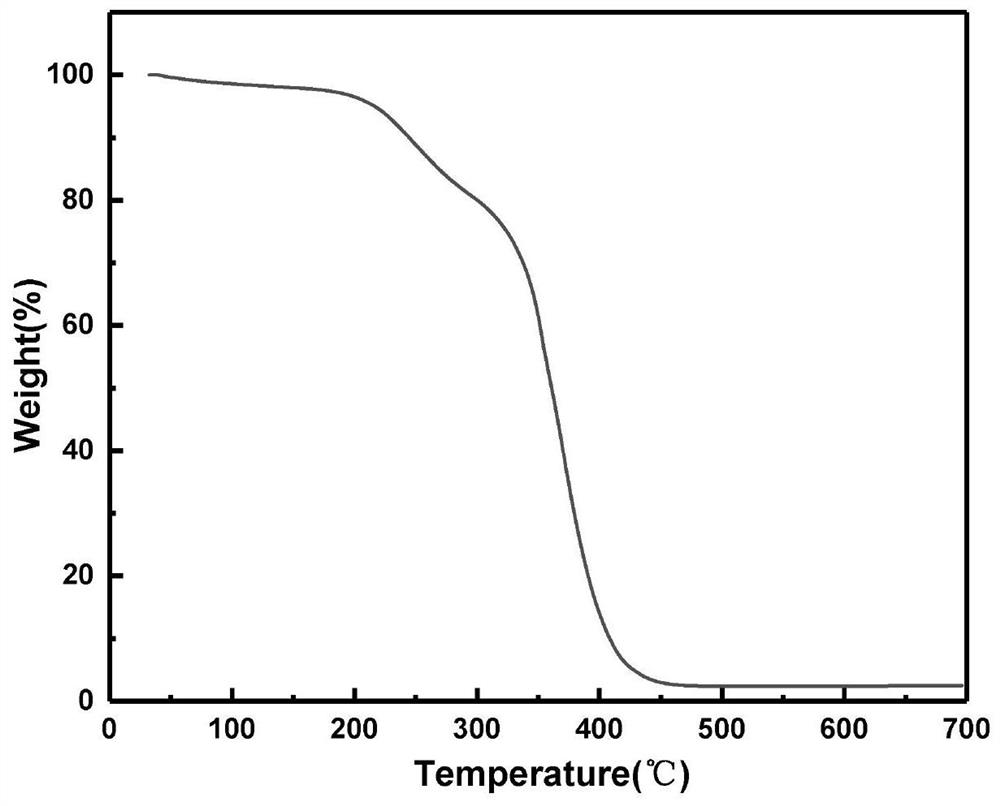

[0039] Step (1) Synthesis of modified polyethyleneimine: 4 g of polyethyleneimine and 4.45 g of absolute ethanol were weighed with an electronic balance. Wherein, polyethyleneimine is polyethyleneimine aqueous solution, and the number average molecular weight is 20000. The polyethyleneimine and absolute ethanol were placed in a three-neck flask with a vent valve, wherein a condenser was connected to the three-necked flask and a thermometer was inserted to form a reactor. Pass argon into the flask and stir with a magnetic stirrer for more than 2 hours. After stirring evenly, add 0.45g of acrylonitrile with a syringe, raise the temperature in the reaction flask to 60°C, stir at 500rmp, and react for 12 hours to obtain acrylonitrile-modified Polyethyleneimine (CN-PEI);

[0040] Step (2) preparation of crosslinked polymer solid state electrolyte: weigh modified polyethyleneimine, lithium salt and crosslinking agent with electronic balance, wherein, the modification ratio of polye...

Embodiment 2

[0053] Step (1) is the same as step (1) of embodiment 1, the difference lies in step (2).

[0054] Step (2) preparation of crosslinked polymer solid state electrolyte: weigh modified polyethyleneimine, lithium salt and crosslinking agent with electronic balance, wherein, the modification ratio of polyethyleneimine is 1:2, lithium salt ( The quality of LiTFSI) is 10% of the total mass of modified polyethyleneimine, lithium salt and crosslinking agent, and the quality of crosslinking agent (Aa) is 8% of the total mass of modified polyethyleneimine, lithium salt and crosslinking agent %. And stir evenly with a magnetic stirrer at room temperature; pour the mixed solution into a polytetrafluoroethylene mold, and perform drying and crosslinking under a certain heating program. The heating program is: first gradually heat up to 85°C, the heating rate is 5°C / h, and finally transferred to a vacuum drying oven, the temperature is 110°C, and the holding time is 2h. After cooling, the ...

Embodiment 3

[0059] Step (1) Synthesis of modified polyethyleneimine: Weigh 4 g of polyethyleneimine and 4.45 g of deionized water with an electronic balance, wherein the polyethyleneimine is an aqueous solution of polyethyleneimine with a number average molecular weight of 5000. Put polyethyleneimine and deionized water in a three-necked bottle with a vent valve, connect a condenser tube to the three-necked bottle and insert a thermometer to form a reactor. After passing through argon and stirring for 2 hours, add 0.65 g of acrylic acid with a syringe, increase the temperature in the reaction bottle to 55 ° C, and continue stirring at a speed of 800 rpm for 10 hours to obtain acrylic acid-modified polyethyleneimine (N-CEPEI); The molar ratio of repeating units of ethyleneimine to modifying monomers is 1:3.

[0060] Step (2) preparation of cross-linked polymer solid electrolyte: weigh modified polyethyleneimine, lithium salt and crosslinking agent with electronic balance, wherein, the modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com