Molybdenum diselenide modified titanium dioxide nano photocatalyst and its preparation method and application

A nano-photocatalyst and titanium dioxide technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the problems of less environmentally friendly coatings, etc., achieve high product yield, effectively remove toxic and harmful gases, and cost-effective cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

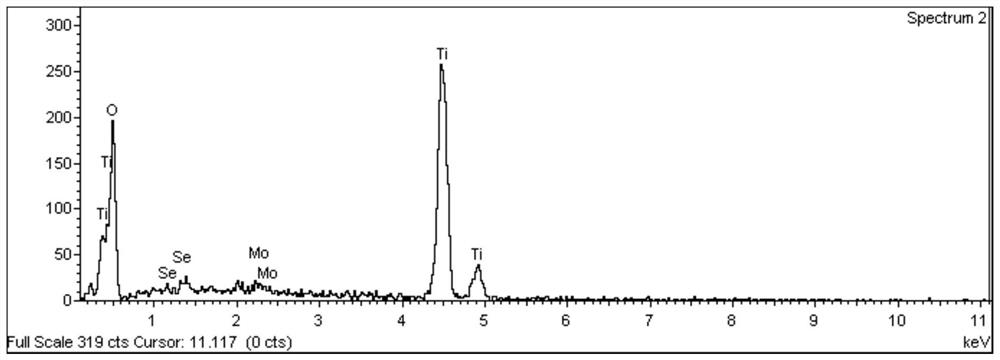

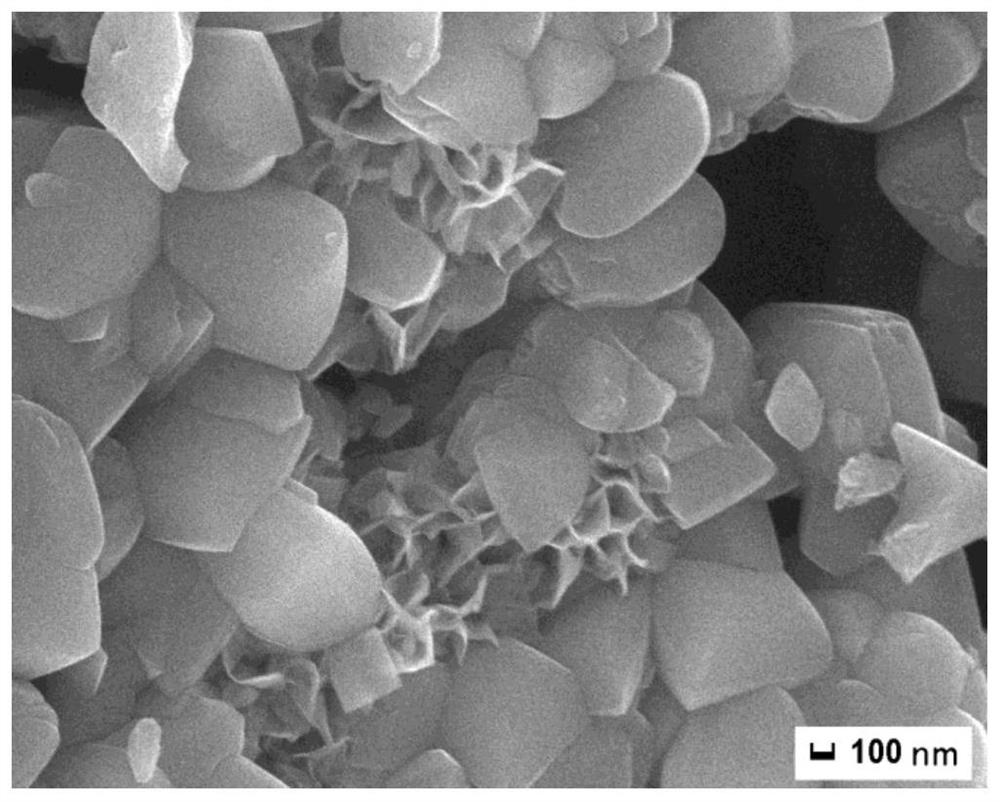

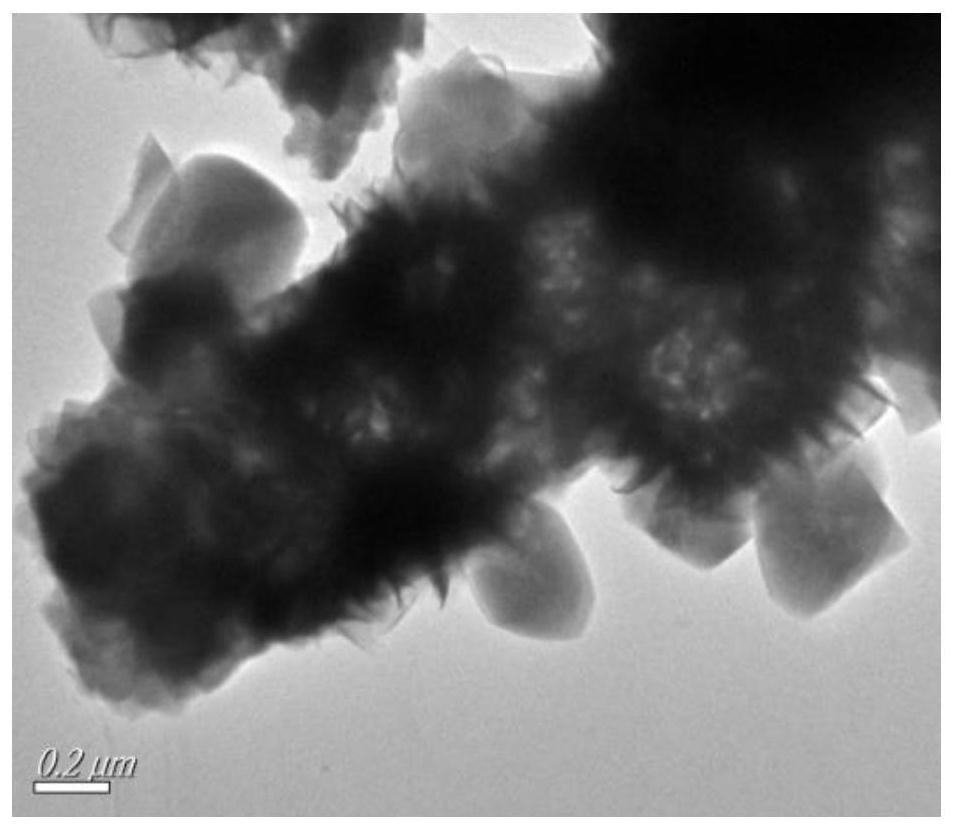

[0024] MoSe 2 / TiO 2 Synthesis of nanophotocatalysts (MoSe 2 content is 5wt%)

[0025] (1) 1.6452g sodium molybdate (Na 2 MoO 4 2H 2 O), 1.5492g selenium (Se) powder, 0.2595g sodium borohydride (NaBH 4 ) was dissolved in 50mL of ethanol aqueous solution (50wt%), magnetically stirred for 30min, then transferred to a 100mL stainless steel reaction kettle, placed in a vacuum oven, kept at 200°C for 6h, and then cooled to room temperature; the prepared black product was transferred to 60 ℃ NaOH solution (50mL, 2mol / L), magnetically stirred for 10min, then transferred to an oven at 80℃ for 2h to remove excess Se, then cooled to room temperature naturally, washed 2-3 times with deionized water and ethanol, respectively, Centrifuge (1600rpm / min), dry in a vacuum oven at 80°C for 24h to obtain MoSe 2 powder.

[0026] (2) According to MoSe 2 In MoSe 2 / TiO 2 In the theoretical value of 5wt%, the MoSe prepared in step (1) 2 Powder 0.02g was dispersed into 50mL of ammonium fl...

Embodiment 2

[0030] MoSe 2 / TiO 2 Synthesis of nanophotocatalysts (MoSe 2 content is 10wt%)

[0031] (1) 1.6452g sodium molybdate (Na 2 MoO 4 2H 2 O), 1.5492g selenium (Se) powder, 0.2595g sodium borohydride (NaBH 4 ) was dissolved in 50mL of ethanol aqueous solution (50wt%), transferred to a 100mL stainless steel reaction kettle after being magnetically stirred for 30min, placed in a vacuum drying oven, kept at 200°C for 6h, and then cooled to room temperature; the prepared black product was transferred to 80 ℃ NaOH solution (50mL, 3mol / ), magnetically stirred for 10min, then transferred to an oven at 80℃ for 2h to remove excess Se, then cooled to room temperature naturally, washed 2-3 times with deionized water and ethanol, and centrifuged Separation (1600rpm / min), drying in a vacuum oven at 80°C for 24h to obtain MoSe 2 powder.

[0032] (2) According to MoSe 2 In MoSe 2 / TiO 2 In the theoretical value of 10wt%, the MoSe prepared in step (1) 2 Powder 0.04g was dispersed into ...

Embodiment 3

[0036] MoSe 2 / TiO 2 Synthesis of nanophotocatalysts (MoSe 2 content is 20wt%)

[0037] (1) 1.6452g sodium molybdate (Na 2 MoO 4 2H 2 O), 1.5492g selenium (Se) powder, 0.2595g sodium borohydride (NaBH 4 ) was dissolved in 50mL of ethanol aqueous solution (50wt%), magnetically stirred for 30min, then transferred to a 100mL stainless steel reaction kettle, placed in a vacuum oven, kept at 200°C for 6h, and then cooled to room temperature; the prepared black product was transferred to NaOH solution (50mL, 2mol / L) at 70°C, magnetically stirred for 10min, then transferred to an oven at 80°C for 2h to remove excess Se, then cooled to room temperature naturally, washed with deionized water and ethanol for 2-3 times respectively , centrifuged (1600rpm / min), and dried in a vacuum oven at 80°C for 24h to obtain MoSe 2 powder.

[0038] (2) According to MoSe 2 In MoSe 2 / TiO 2 In the theoretical value of 20wt%, the MoSe prepared in step (1) 2 Powder 0.08g was dispersed into 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com