Treatment technology of ester-containing organic wastewater

A technology of organic wastewater and treatment process, applied in water/sewage treatment, water/sewage multi-stage treatment, special compound water treatment, etc., can solve the problems of high investment cost, low treatment efficiency, large land occupation, etc., and achieve salt crystallization The effect is good, the process is smooth, and the effect of high current resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

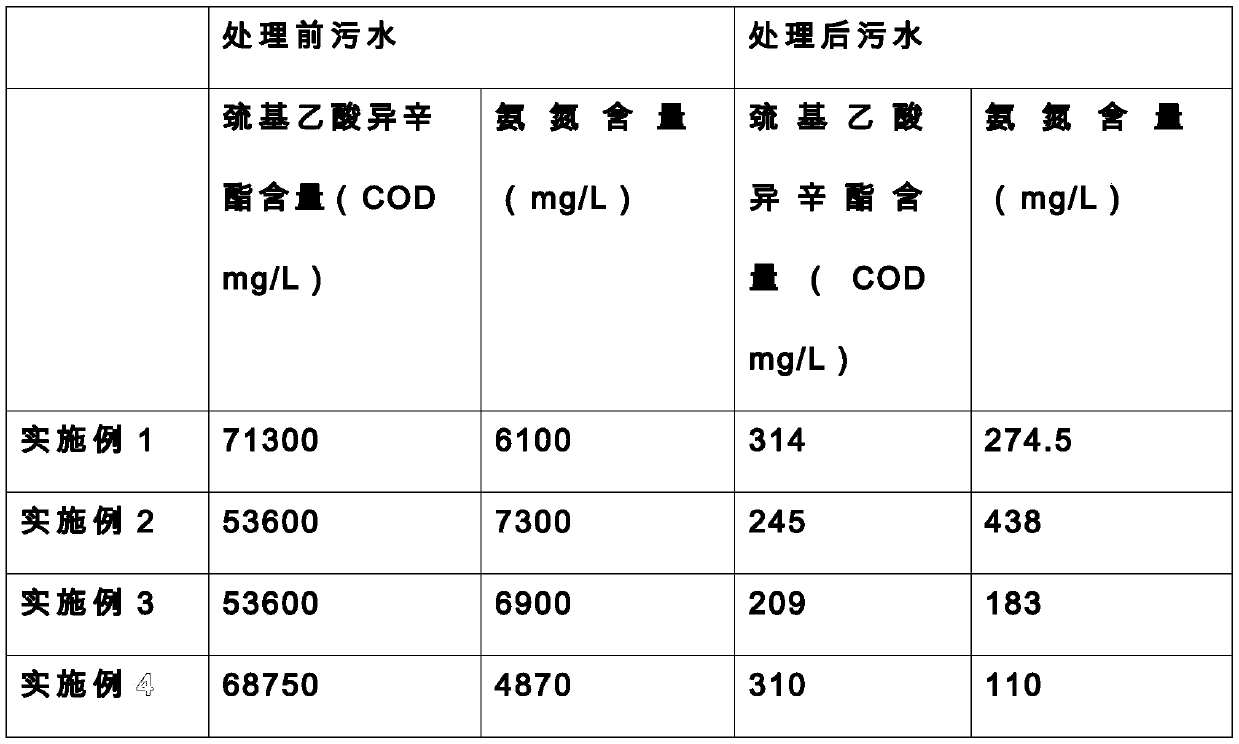

Embodiment 1

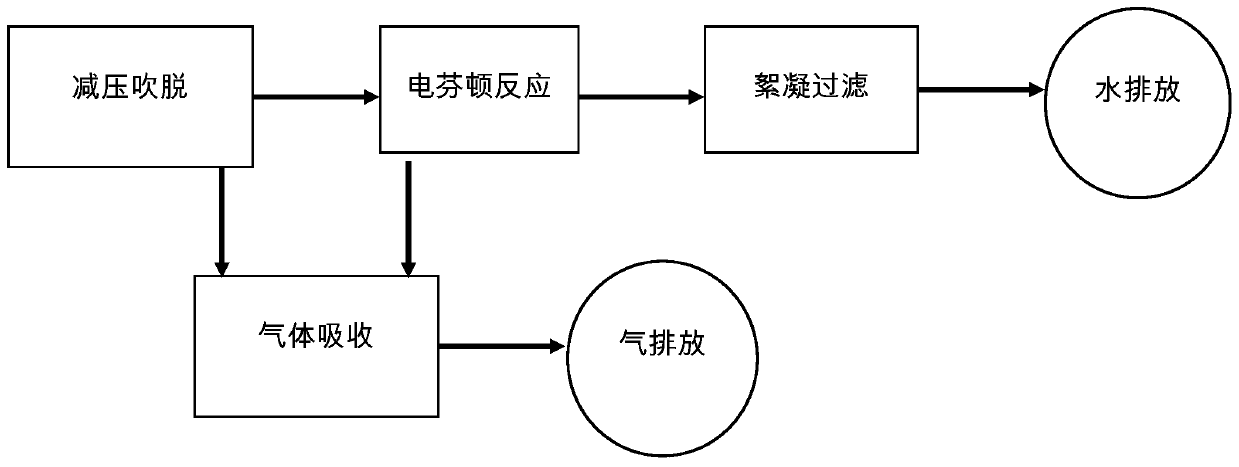

[0038] A treatment process for ester-containing organic waste water, comprising the steps of:

[0039] If a large amount of ammonia-containing substances have been mixed in the wastewater to be treated, the pH of the wastewater to be treated must be adjusted to above 10. First carry out the atomization and absorption treatment of vacuum deamination, and continuously reflux the treated liquid obtained by condensation until the pH is 8; then add flocculant to the obtained wastewater to remove methyl, hydroxyl, ether, phenol and other chemicals derivative. If there are no these ingredients can not be added, to obtain the treatment solution I;

[0040] Add acid to the treatment solution I, adjust the pH to 2, add hydrogen peroxide and FeSO 4 Doped with Ti, FeSO 4 The doped Ti is added in the form of a solution, and its volume concentration is 0.1% of the total liquid to obtain the treatment solution II, which is left overnight;

[0041] Pour the treatment solution II into the ...

Embodiment 2

[0045] A treatment process for ester-containing organic waste water, comprising the steps of:

[0046] If a large amount of ammonia-containing substances have been mixed in the wastewater to be treated, the pH of the wastewater to be treated must be adjusted to above 10. First carry out the atomization and absorption treatment of vacuum deamination, and continuously reflux the condensed liquid to be treated until pH = 8; then add flocculant to the obtained wastewater to remove methyl groups, hydroxyl groups, ethers, phenols, etc. Chemical derivatives to obtain treatment solution I;

[0047] Add acid to the treatment solution I, adjust the pH to 3, add hydrogen peroxide and FeSO 4 Doped with Co, FeSO 4 The doped Co is added as a solution, and its volume concentration is 0.5% of the total liquid volume to obtain the treatment solution II, which is left overnight;

[0048] Pour the treatment solution II into the electric Fenton reactor for energization reaction, adjust the cur...

Embodiment 3

[0052] Under the configuration of high-voltage and high-frequency power supply, a treatment process for ester-containing organic wastewater includes the following steps:

[0053] If a large amount of ammonia-containing substances have been mixed in the wastewater to be treated, the pH of the wastewater to be treated must be adjusted to above 10. First carry out the atomization and absorption treatment of vacuum deamination, and continuously reflux the treated liquid obtained by condensation until pH=7.5; then add flocculant to the obtained wastewater to remove methyl groups, hydroxyl groups, ethers, phenols, etc. Chemical derivatives to obtain treatment solution I;

[0054] Add acid to the treatment solution I, adjust the pH to 3, add hydrogen peroxide and FeSO 4 Doped with Ti, FeSO 4 Doped Ti is added in solution, FeSO 4 The volumetric concentration of the solution is 0.5% of the total liquid amount to obtain the treatment solution II, which is placed overnight;

[0055] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com