Nanocellulose-polymer composite hydrogel as well as preparation method and application thereof

A nanocellulose and composite hydrogel technology, applied in electromagnetic measurement devices, electric/magnetic solid deformation measurement, etc., can solve the problems of easy degradation and poor stability, and achieve the effects of simple operation, low cost and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of nanocellulose-polymer composite hydrogel, comprising the steps of:

[0039] 1) preparing a cellulose nanoparticle dispersion with a mass fraction of 10%;

[0040] 2) Add Fenton's reagent to the cellulose nanoparticle dispersion, the concentration of Fenton's reagent in the system is 30mmol / L, and stir for 5min to form the first mixed solution;

[0041] 3) Add acrylic acid and N,N'-methylenebisacrylamide to the first mixed solution, the concentration of acrylic acid in the system is 3mol / L, and the concentration of N,N'-methylenebisacrylamide in the system is 50mmol / L, stirred for 10min to form the second mixed solution;

[0042] 4) Pour the second mixed solution into a polytetrafluoro mold and keep it at 60° C. for 2 hours to obtain a nanocellulose-polymer hydrogel.

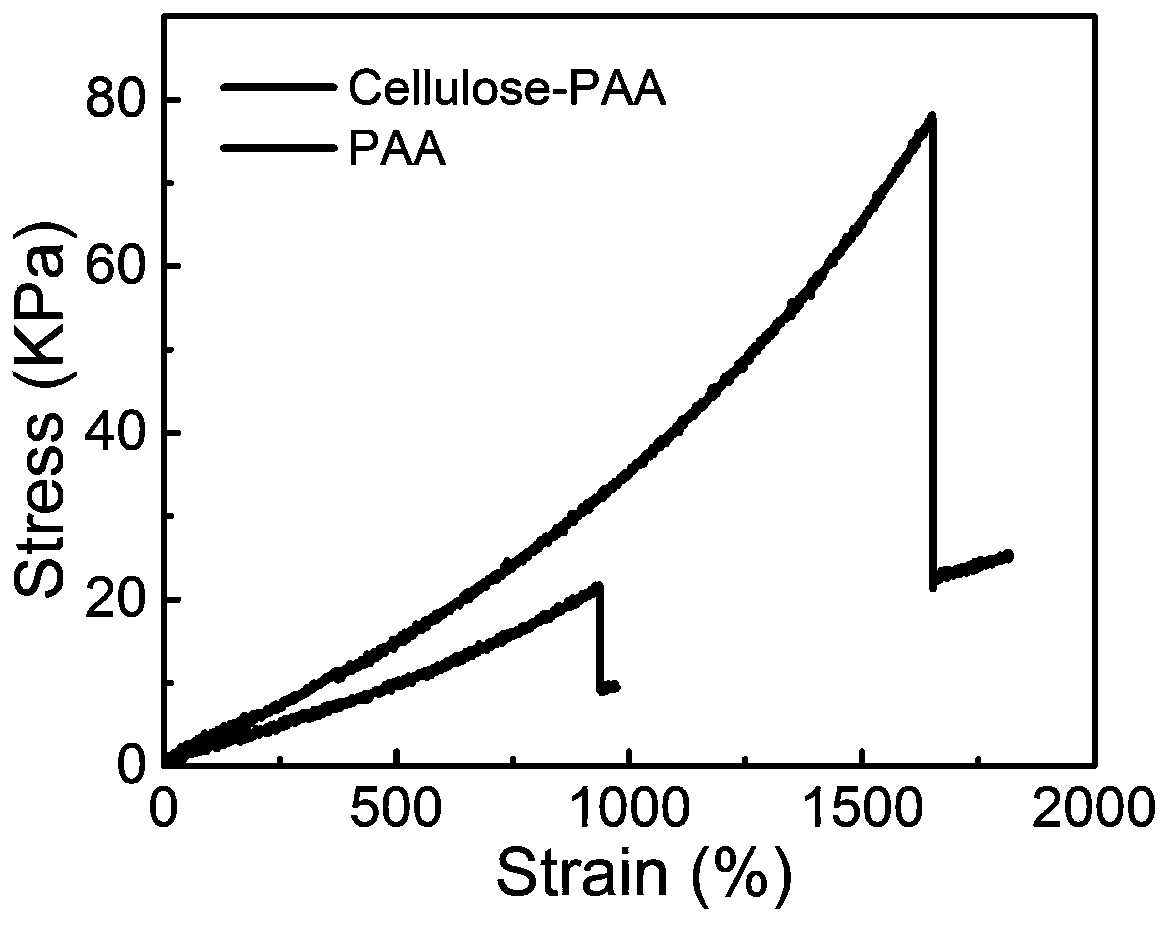

[0043] The tensile mechanical properties of the nanocellulose-polymer hydrogel prepared in this example are as follows: figure 1 As shown, compared with pure polyacrylic acid hy...

Embodiment 2

[0045] A preparation method of nanocellulose-polymer composite hydrogel, comprising the steps of:

[0046] 1) preparing a mass fraction of 3% cellulose nanofiber dispersion;

[0047] 2) Add ammonium persulfate to the cellulose nanofiber dispersion, the concentration of ammonium persulfate in the system is 20mmol / L, and stir for 5min to form the first mixed solution;

[0048] 3) Add acrylamide and N,N'-methylenebisacrylamide to the first mixed solution, the concentration of acrylamide in the system is 3mol / L, and the concentration of N,N'-methylenebisacrylamide in the system 50mmol / L, stirred for 10min to form the second mixed solution;

[0049] 4) Pour the second mixed solution into a polytetrafluoro mold and keep it at 60° C. for 4 hours to obtain a nanocellulose-polymer hydrogel hydrogel.

Embodiment 3

[0051]A preparation method of nanocellulose-polymer composite hydrogel, comprising the steps of:

[0052] 1) preparing a cellulose nanofiber dispersion with a mass fraction of 1%;

[0053] 2) Add ammonium persulfate solution to the cellulose nanofiber dispersion, the concentration of ammonium persulfate in the system is 40mmol / L, and stir for 5min to form the first mixed solution;

[0054] 3) Add acrylamide, N-isopropylacrylamide and N,N'-methylenebisacrylamide to the first mixed solution, the concentration of acrylamide in the system is 1mol / L, and N-isopropylacrylamide The concentration in the system is 1mol / L, the concentration of N,N'-methylenebisacrylamide in the system is 40mmol / L, and stirred for 10min to form the second mixed solution;

[0055] 4) Pour the second mixed solution into a polytetrafluoro mold and keep it at 60° C. for 1 hour to obtain a nanocellulose-polymer hydrogel.

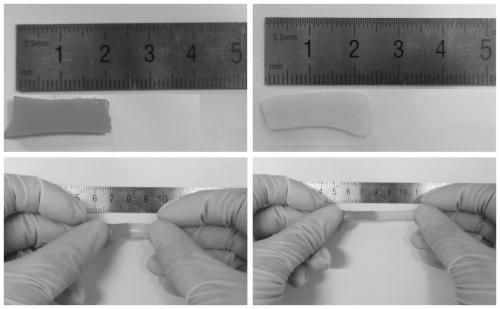

[0056] The self-healing properties of the nanocellulose-polymer hydrogel prepared in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com