Soil conditioner for repairing cadmium-arsenic compound polluted farmland and preparation method thereof

A soil conditioner and compound pollution technology, applied in the field of farmland soil remediation, can solve problems such as excessive cadmium and arsenic, and achieve the effects of simple production method, favorable industrial production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

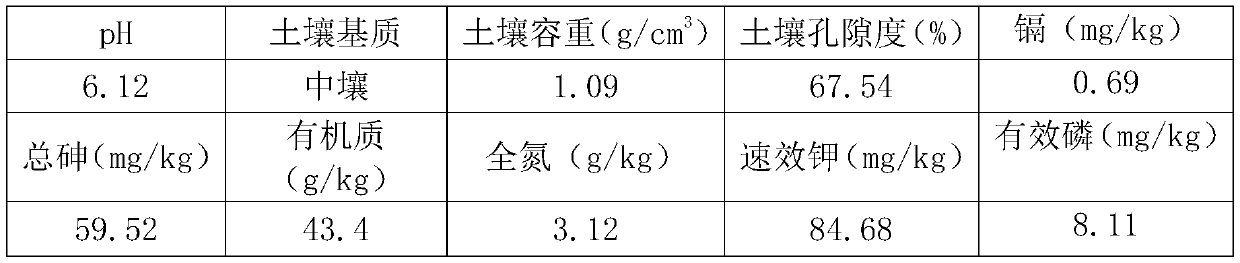

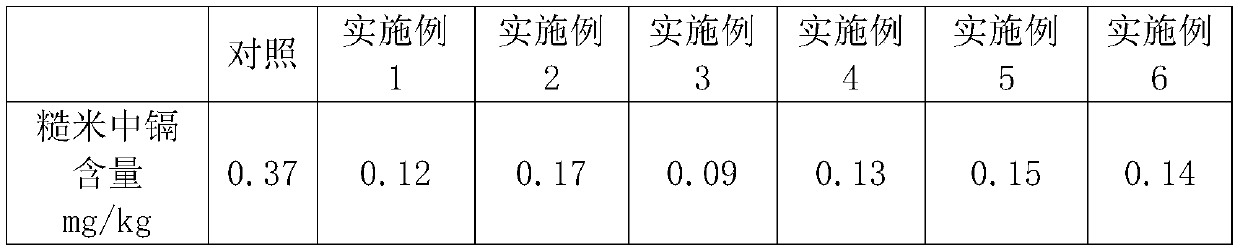

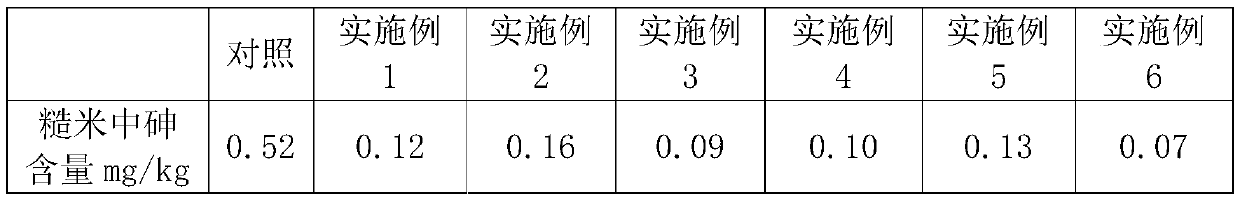

Examples

Embodiment 1

[0045] A soil conditioner for repairing cadmium-arsenic composite polluted farmland, comprising the following raw materials in parts by weight:

[0046] 40 parts of calcium carbonate, 20 parts of magnesium oxide, 10 parts of gypsum powder, 10 parts of humic acid, 10 parts of hydroxy iron pillared attapulgite, 10 parts of sodium silicate.

[0047] The preparation method of described hydroxyl iron pillared attapulgite is:

[0048] 1): According to the molar ratio NaOH / FeCl 2 =2.1:1, slowly inject 0.5mol / L NaOH solution into 0.5mol / L FeCl with constant aeration and stirring 2 Then, add water to adjust the pH value of the solution to 6.5, the color to deep red, and then leave it at room temperature for 24 hours to obtain the hydroxyl iron pillar solution.

[0049] 2): Attapulgite and water are mixed and ball-milled at a volume ratio of 1:2 to prepare an attapulgite slurry, and the prepared hydroxyl iron pillar liquid is slowly added to the attapulgite slurry to control the iron ...

Embodiment 2

[0052] A soil conditioner for repairing cadmium-arsenic composite polluted farmland, comprising the following raw materials in parts by weight:

[0053] 40 parts of gypsum powder, 20 parts of magnesium oxide, 10 parts of shell powder, 15 parts of sodium silicate, 10 parts of humic acid, 15 parts of hydroxy iron pillared attapulgite;

[0054] The preparation method of described hydroxyl iron pillared attapulgite is:

[0055] 1): According to molar ratio Ca(OH) 2 / FeCl 2 =0.7:1, the Ca(OH) of 0.02mol / L 2 The solution is slowly injected into 0.3mol / L FeCl in an aerated state 2 Then, add water to adjust the pH value of the solution to 8.6, the color to deep red, and then leave it at room temperature for 24 hours to obtain the hydroxy iron pillar solution.

[0056] 2): Attapulgite and water are mixed and ball-milled at a volume ratio of 1:2 to prepare attapulgite slurry, and the prepared hydroxyl iron pillar liquid is slowly added to the stirred attapulgite slurry with a perist...

Embodiment 3

[0059] A soil conditioner for repairing cadmium-arsenic composite polluted farmland, comprising the following raw materials in parts by weight:

[0060] Calcium carbonate 40 parts, magnesium oxide 25 parts, disiloxane 15 parts, humic acid 10 parts, hydroxy iron pillared attapulgite 10 parts.

[0061] The preparation method of described hydroxyl iron pillared attapulgite is:

[0062] 1): According to molar ratio Ca(OH) 2 / FeSO 4 =0.55:1, the Ca(OH) of 0.02mol / L 2 The solution is slowly injected into 1.0mol / L FeSO with continuous aeration and stirring 4 Then, add water to adjust the pH value of the solution to 6.5, the color to deep red, and then leave it at room temperature for 24 hours to obtain the hydroxyl iron pillar solution. (Because calcium sulfate is generated in the process, calcium sulfate is slightly soluble and wraps calcium hydroxide, preventing the reaction from proceeding further, so it has an impact on pH).

[0063] 2): Attapulgite and water are mixed and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com