Adhesive for colored stone tiles, and preparation method and using method thereof

A technology of adhesives and colored stones, applied in the direction of adhesive types, ester copolymer adhesives, amide/imide polymer adhesives, etc., can solve the problem of non-whitening and foaming, and production Problems such as unstable process and large amount of epoxy resin are used to achieve excellent bonding effect, good bonding effect, and water resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

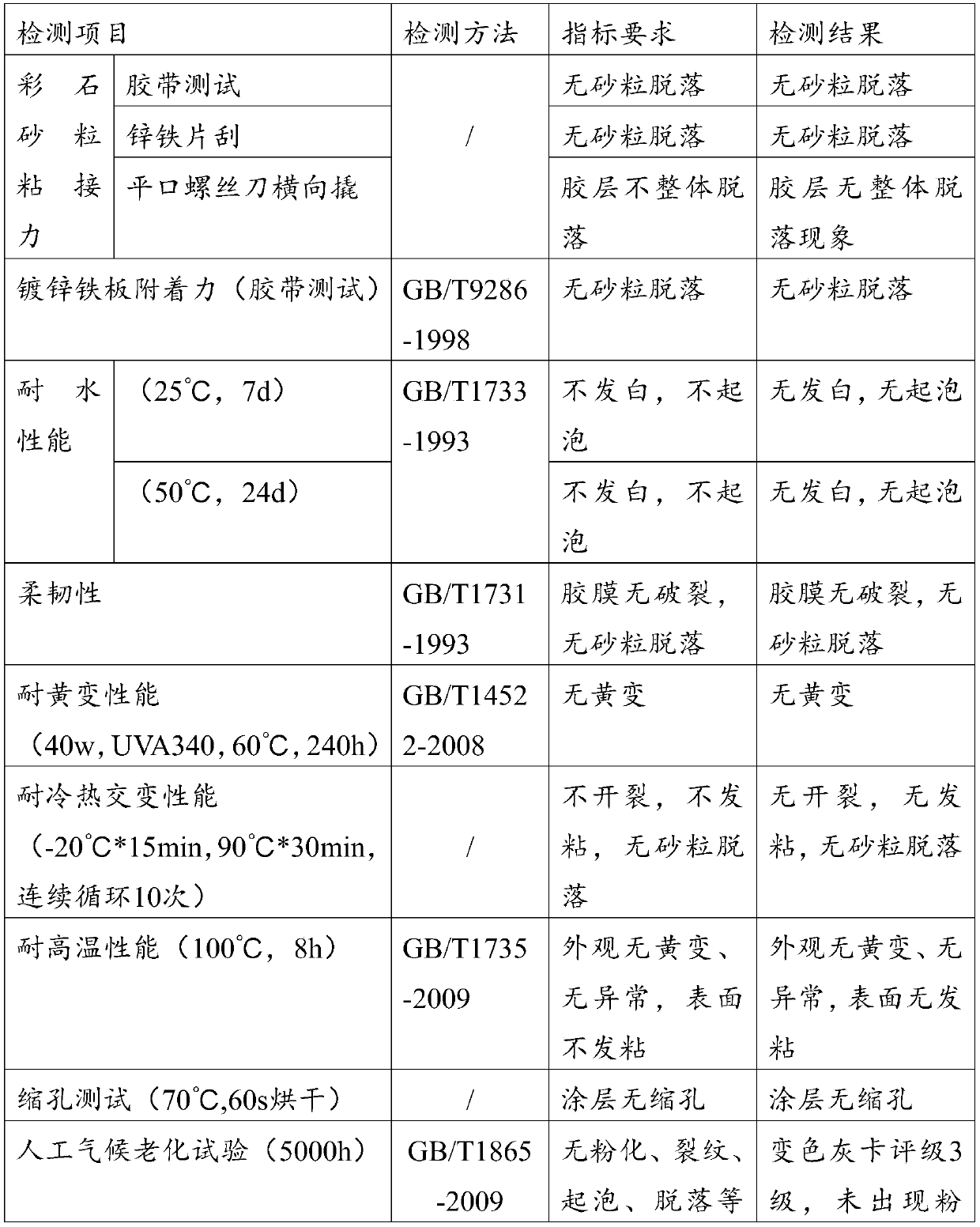

Examples

preparation example Construction

[0079] Correspondingly, the present invention also discloses a method for preparing an adhesive for colored stone tiles, including:

[0080] (1) Preparation of primer:

[0081] (2) Preparation of surface glue:

[0082] (3) Store the base glue and top glue separately.

[0083] Wherein, step (1) prepares base glue, comprises:

[0084] (A) Add 4 / 5 emulsifier and water into the reaction kettle, start the mixer at a speed of 65-75 rpm, and then add butyl acrylate, isooctyl acrylate, methacrylic acid, methyl methacrylate, tertiary carbonic acid Add vinyl ester or glycidyl tert-carbonate and hydroxyethyl methacrylate to the reaction kettle, and emulsify at room temperature for 20-50 minutes;

[0085] (B) After the emulsification is complete, release 13-15% of the emulsion, stir the remaining 85-87% of the emulsion with N-methylolacrylamide, acrylamide, and water, and release after stirring evenly for use;

[0086] (C) The 13-15% emulsion, the remaining 1 / 5 emulsifier and water ar...

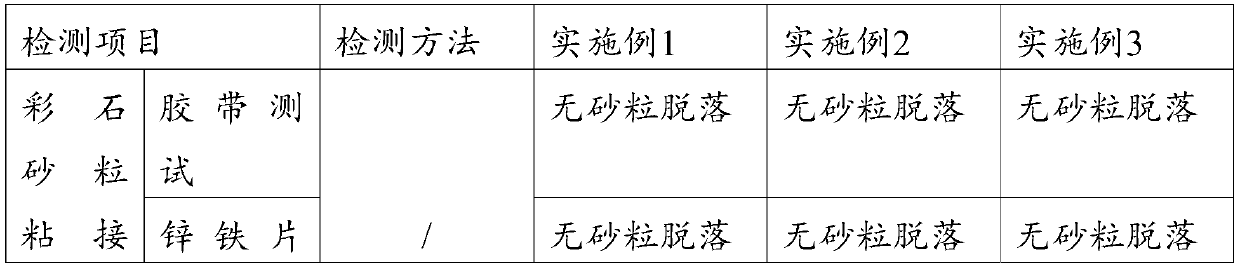

Embodiment 1

[0115] (1) Formula:

[0116] (1) Primer: 8 parts of butyl acrylate, 3 parts of isooctyl acrylate, 1 part of methacrylic acid, 12 parts of methyl methacrylate, 0.5 parts of vinyl tert-carbonate, 0.1 part of hydroxyethyl methacrylate, N - 1 part of methylol acrylamide, 0.5 part of acrylamide, 53.1 parts of water, 1 part of emulsifier, 0.1 part of ammonium persulfate, 1 part of ammonia water, 1 part of the first auxiliary agent.

[0117] (2) Face glue: 12 parts of butyl acrylate, 12 parts of methyl methacrylate, 3 parts of cyclohexyl methacrylate, 0.1 part of methacrylic acid, 0.1 part of vinyl tertiary carbonate, 52 parts of water, 1 part of emulsifier , 1 part of N-methylolacrylamide, 0.1 part of acrylamide, 0.01 part of sodium bicarbonate, 0.1 part of ammonium persulfate, 0.5 part of TMPTA or AMA, 0.1 part of ammonia water, and 1 part of the second additive.

[0118] (2) Preparation method:

[0119] (1) Preparation of primer: Add 4 / 5 of 1 part of emulsifier and 14 parts of w...

Embodiment 2

[0131] (1) Formula:

[0132] (1) Primer: 12 parts of butyl acrylate, 5 parts of isooctyl acrylate, 0.9 parts of methacrylic acid, 18 parts of methyl methacrylate, 1.2 parts of glycidyl tertiary carbonate, 0.7 parts of hydroxyethyl methacrylate, 3 parts of N-methylolacrylamide, 1 part of acrylamide, 59.2 parts of water, 0.6 parts of emulsifier, 0.2 parts of ammonium persulfate, 2 parts of ammonia water, and 2 parts of the first additive.

[0133] (2) Face glue: 16.5 parts of butyl acrylate, 16.5 parts of methyl methacrylate, 6 parts of cyclohexyl methacrylate, 0.25 parts of methacrylic acid, 0.55 parts of glycidyl tertiary carbonate, 52 parts of water, 1.2 parts of emulsifier 3 parts, N-methylolacrylamide 3 parts, acrylamide 0.3 parts, sodium bicarbonate 0.03 parts, ammonium persulfate 0.3 parts, TMPTA 1.2 parts, ammonia water 0.2 parts, the second auxiliary agent 2 parts.

[0134] (2) Preparation method:

[0135] (1) Preparation of primer: Add 4 / 5 of 0.6 parts of emulsifier ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com