Synthetic additive type long-acting antifreezing cooling liquid and preparation method thereof

A technology of antifreeze coolant and additives, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of unsatisfactory comprehensive performance of antifreeze coolant, harmful to human body and environment, poor aluminum protection effect, etc., and achieve long-term inhibition Corrosion ability, avoid cavitation corrosion, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

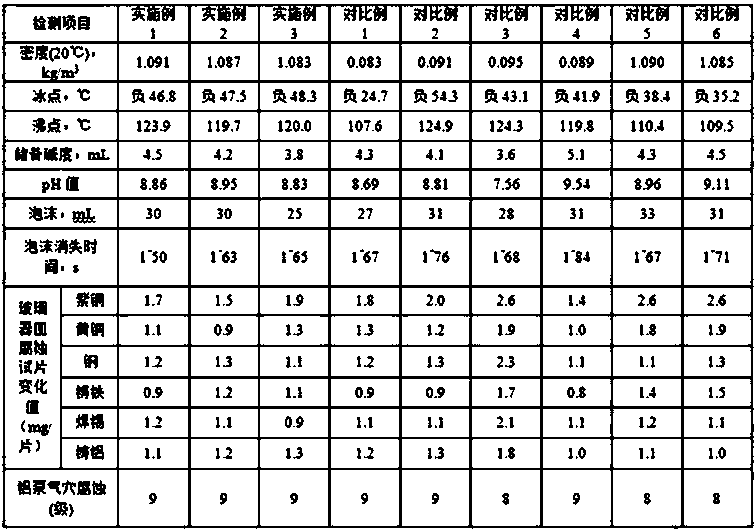

Examples

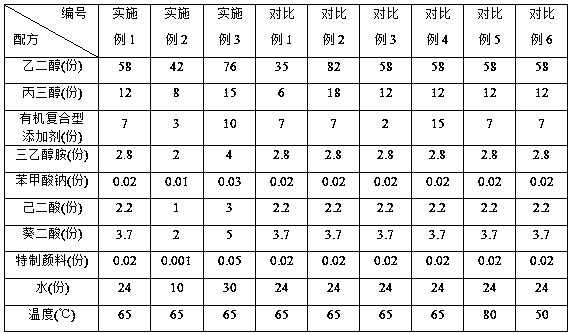

Embodiment 1

[0029] A synthetic additive type long-acting antifreeze coolant, comprising the following components in parts by weight: 58 parts of ethylene glycol, 12 parts of glycerin, 7 parts of organic composite additives, 2.8 parts of triethanolamine, and 0.02 parts of sodium benzoate , 2.2 parts of adipic acid, 3.7 parts of sebacic acid, 0.02 parts of special pigments and 24 parts of water.

[0030] A method for preparing a synthetic additive-type long-acting antifreeze coolant, comprising the following steps: S1. Mixing deionized water, ethylene glycol and glycerol, heating and stirring in a water bath at 65°C for 25 minutes at a speed of 100 r / min; S2. Mix compound additives, triethanolamine, special pigments and deionized water, and stir evenly at 100 r / min; S3. Add the mixed solution obtained in S2, sodium benzoate, adipic acid, and sebacic acid to the mixed solution obtained in S1, and place in a 65°C water bath Heat and stir for 18 minutes at a speed of 400 r / min to obtain an ant...

Embodiment 2

[0032] A synthetic additive type long-acting antifreeze coolant, comprising the following components in parts by weight: 42 parts of ethylene glycol, 8 parts of glycerin, 3 parts of organic composite additives, 2 parts of triethanolamine, and 0.01 part of sodium benzoate , 1 part of adipic acid, 2 parts of sebacic acid, 0.001 part of special pigment and 10 parts of water.

[0033] A method for preparing a synthetic additive-type long-acting antifreeze coolant, comprising the following steps: S1. Mixing deionized water, ethylene glycol and glycerol, heating and stirring in a water bath at 65°C for 25 minutes at a speed of 100 r / min; S2. Mix compound additives, triethanolamine, special pigments and deionized water, and stir evenly at 100 r / min; S3. Add the mixed solution obtained in S2, sodium benzoate, adipic acid, and sebacic acid to the mixed solution obtained in S1, and place in a 65°C water bath Heat and stir for 18 minutes at a speed of 400 r / min to obtain an antifreeze co...

Embodiment 3

[0035]A synthetic additive type long-acting antifreeze cooling liquid, comprising the following components in parts by weight: 76 parts of ethylene glycol, 15 parts of glycerin, 10 parts of organic composite additives, 4 parts of triethanolamine, and 0.03 parts of sodium benzoate , 3 parts of adipic acid, 5 parts of sebacic acid, 0.05 parts of special pigment and 30 parts of water.

[0036] A method for preparing a synthetic additive-type long-acting antifreeze coolant, comprising the following steps: S1. Mixing deionized water, ethylene glycol and glycerol, heating and stirring in a water bath at 65°C for 25 minutes at a speed of 100 r / min; S2. Mix compound additives, triethanolamine, special pigments and deionized water, and stir evenly at 100 r / min; S3. Add the mixed solution obtained in S2, sodium benzoate, adipic acid, and sebacic acid to the mixed solution obtained in S1, and place in a 65°C water bath Heat and stir for 18 minutes at a speed of 400 r / min to obtain an ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com