Preparation method and application of low-grade attapulgite modified material

A technology of attapulgite and modified materials, applied in the directions of application, soil conditioning materials, chemical instruments and methods, etc., can solve the problems of low utilization rate of low-grade attapulgite, etc., and achieve the effect of improving pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1, the preparation method of low-grade attapulgite modified material

[0053] The preparation method of the low-grade attapulgite modified material comprises the following steps:

[0054] (1) Attapulgite clay pretreatment: After the low-grade attapulgite clay raw ore is crushed, crushed, and ground through a 100-mesh sieve, soak in distilled water for 24 hours at a soil-water ratio of 200g / L; Stir at 600r / min for 5h, let stand to separate layers, separate the sediment at the bottom, dry the attapulgite clay slurry at 105°C to obtain a dry sample; grind it through a 100-mesh sieve and save it for later use.

[0055] (2) Ethylenediamine modification reaction:

[0056] Use 1%-15% (v / v) ethylenediamine solution and natural attapulgite as the solvent, mix them according to the solid-to-liquid ratio of 50-200g / L, put them in a 100ml hydrothermal reaction kettle, tighten them and put them into an electric heating constant temperature blast Hydrothermal reaction at...

Embodiment 2

[0060] Embodiment 2, characterization of low-grade attapulgite modified material

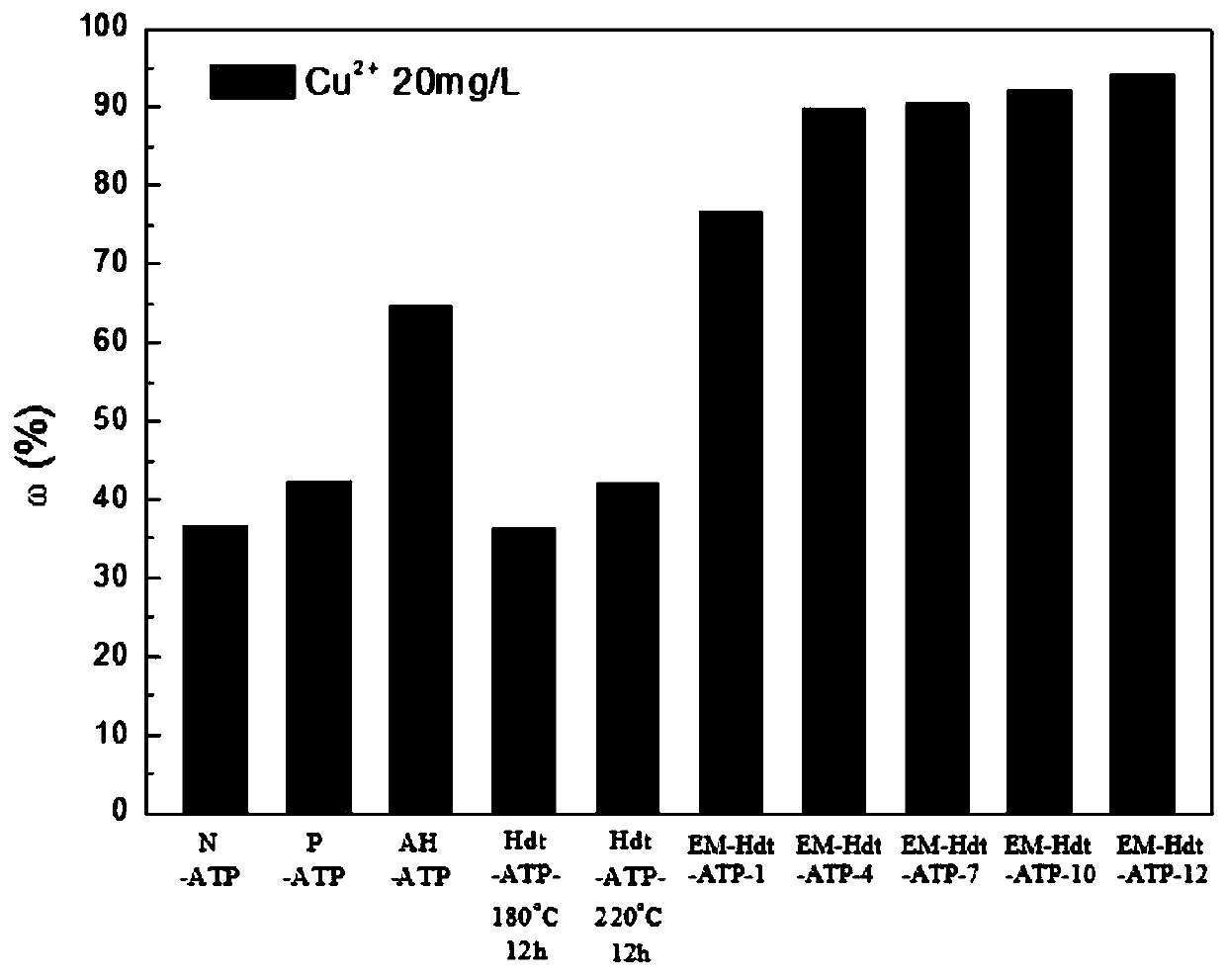

[0061] In order to compare the improvement of the soil environment by low-grade attapulgite ores treated in different ways, except for the ethylenediamine-modified hydrothermally activated low-grade attapulgite modified material (EM-Hdt-ATP) prepared according to the method in Example 1 , and the other four attapulgite modified materials were also prepared according to the following four methods.

[0062] (1) Pretreatment of attapulgite clay: firstly, the attapulgite raw soil is roughly crushed, crushed, and ground through a 100-mesh sieve to obtain natural attapulgite clay (raw ore), which is placed in an electric heating constant temperature blast drying oven at 105°C Preserve after drying under high temperature, natural attapulgite clay (raw ore) is recorded as N-ATP;

[0063] (2) Purification of attapulgite clay: the natural attapulgite clay was purified by stirring-stationary layering meth...

Embodiment 3

[0068] Embodiment 3, material characterization analysis

[0069] Fourier Transform Infrared Spectroscopy (FTIR):

[0070] The test sample powder is scanned by ATR total reflection spectrum, and the configured MCT detector works under the cooling protection of liquid nitrogen. The resolution of the infrared spectrometer is 4cm -1 , in the test, 64 scans are superimposed, and the range of scanning wavenumber is 450cm -1 -4000cm -1 .

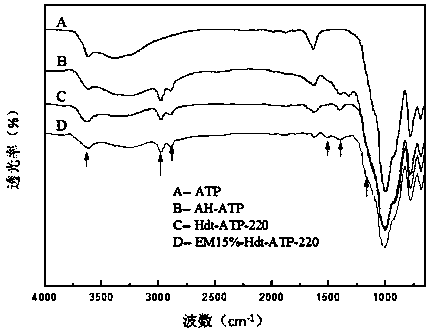

[0071] Four kinds of attapulgite clays except raw ore obtained by the ethylenediamine modified hydrothermally activated attapulgite material 1 (EM-Hdt-ATP-12) prepared by the method of Example 1 and the method in Example 2 Infrared spectroscopy (FTIR) analysis of its modified materials, infrared spectroscopy is the most commonly used means of characterization of attapulgite, can be divided into three bands: one is 3700-3200cm -1 The peak at the -O-H stretching vibration region; the second band is 1700-1600cm -1 , this band is the H-O-H bendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com