Flexible Mo-MoOX-based solar energy absorbing coating and preparation method thereof

A technology of solar energy absorption and mo-moox, which is applied in the field of flexible solar photothermal, can solve the problems of complex coating preparation process, increase coating preparation cost, unfavorable industrial production, etc., and achieve enhanced light absorption efficiency and good photothermal conversion characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in further detail below in conjunction with accompanying drawing:

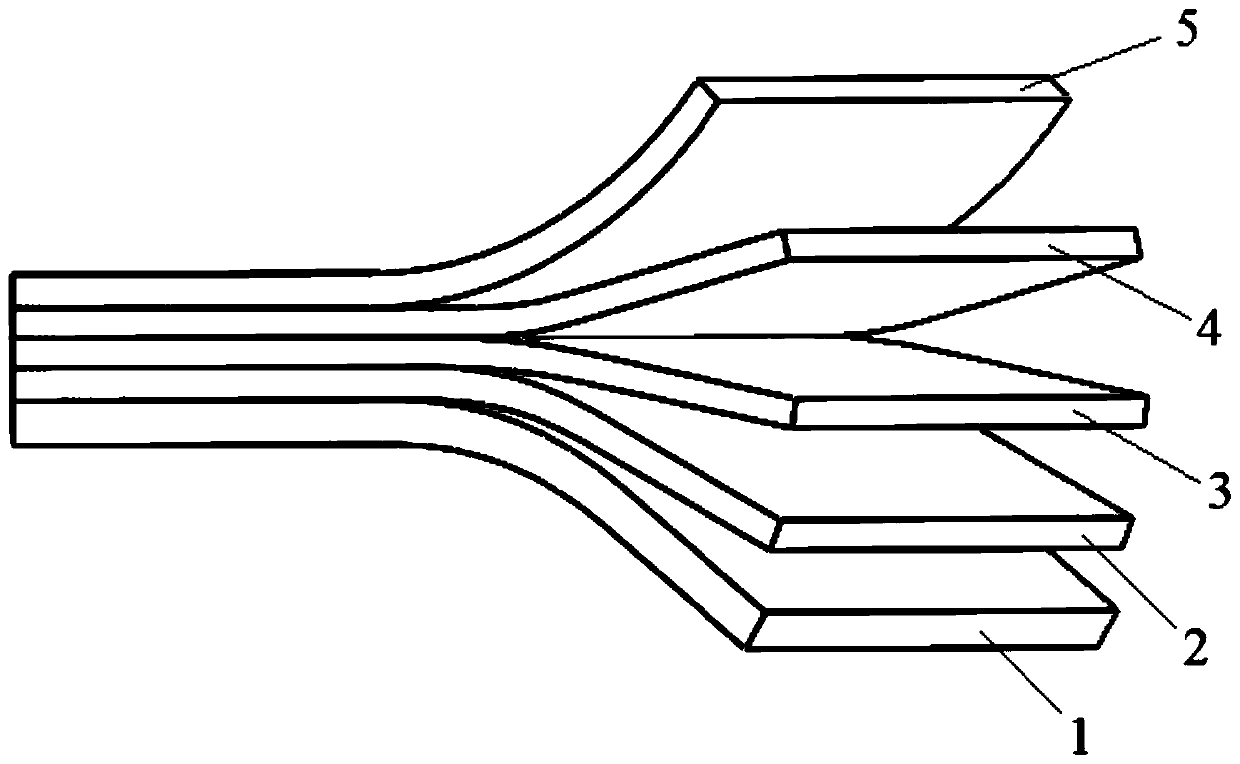

[0033] like figure 1As shown, a flexible Mo-MoO provided by the present invention x The base solar absorbing coating comprises a base 1, on which an infrared reflective layer 2, a high absorbing layer 3, a low absorbing layer 4 and an antireflection layer 5 are arranged in sequence from bottom to top.

[0034] The material of the base 1 is a flexible polymer or a wearable fabric, specifically, the flexible polymer is a polyethylene terephthalate film (PET) or a polyimide film (PI); the wearable fabric Available in cotton or polyester.

[0035] The infrared reflective layer 2 is a metal molybdenum layer with a thickness of 50-150nm; the metal molybdenum has a very high melting point, stable chemical properties, low thermal diffusivity, and has good adhesion with the material as the substrate 1, ensuring that the coating Structural stability; metal molybdenum has very...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap