A ternary positive electrode material coated with lithium phosphate and conductive carbon material and its preparation method and application

A positive electrode material, conductive carbon technology, applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems that the electrical conductivity and ion conductivity cannot be improved at the same time, and achieve the effect of improving cycle stability, increasing diffusion rate, and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

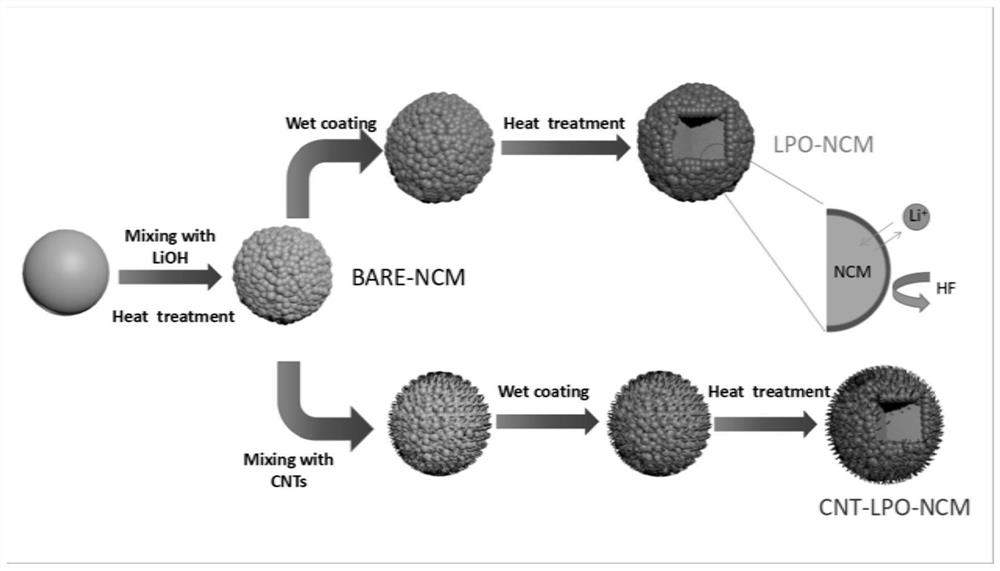

[0039] Preparation of LiNi coated with lithium phosphate and conductive carbon material by liquid phase chemical polymerization 0.8 co 0.1 mn 0.1 o 2 Cathode material.

[0040] S1. Weigh 0.02g of phosphoric acid and dissolve it in anhydrous ethanol solution, sonicate at room temperature for 15min and then continue magnetic stirring for 2h;

[0041] S2. Next, take 4g of ternary positive electrode material and 0.08g of carbon nanotubes, mix and grind the ternary positive electrode material and carbon nanotubes evenly;

[0042] S3. Add the above powder into the solution being stirred, and stir for 1 h;

[0043] S4. Transfer the above solution to an oil bath at 80°C and stir until the ethanol solution is evaporated to dryness, then put it in a drying oven

[0044] Drying to obtain a ternary positive electrode material (CNT-LPO-NCM) coated with lithium phosphate and conductive carbon material;

[0045] S5. The assembled battery was first activated for 2 cycles at a rate of 0....

Embodiment 2

[0050] Preparation of LiNi coated with lithium phosphate and conductive carbon material by liquid phase chemical polymerization 0.8 co 0.1 mn 0.1 o 2 Cathode material.

[0051] S1. Weigh 0.04g of phosphoric acid and dissolve it in anhydrous ethanol solution, sonicate at room temperature for 15min and then continue magnetic stirring for 2h;

[0052] S2. Then, take 4g ternary positive electrode material and 0.08g graphene, mix and grind the ternary positive electrode material and graphene evenly;

[0053] S3. Add the above powder into the solution being stirred, and stir for 1 h;

[0054] S4. Transfer the above solution to an oil bath at 80°C and stir until the ethanol solution is evaporated to dryness, then put it in a drying oven

[0055] Drying to obtain a ternary positive electrode material coated with lithium phosphate and conductive carbon material;

[0056] S5. The assembled battery was first activated for 2 cycles at a rate of 0.1C, and then cycled for 5 cycles at ...

Embodiment 3

[0059] Preparation of LiNi coated with lithium phosphate and conductive carbon material by liquid phase chemical polymerization 0.8 co 0.1 mn 0.1 o 2 Cathode material.

[0060] S1. Weigh 0.04g of phosphoric acid and dissolve it in anhydrous ethanol solution, sonicate at room temperature for 15min and then continue magnetic stirring for 2h;

[0061] S2. Next, weigh 4g of ternary positive electrode material and 0.04g of acetylene black, mix and grind the ternary positive electrode material and acetylene black evenly;

[0062] S3. Add the above powder into the solution being stirred, and stir for 1 h;

[0063] S4. Transfer the above solution to an oil bath at 80°C and stir until the ethanol solution is evaporated to dryness, then put it in a drying oven

[0064] Drying to obtain a ternary positive electrode material coated with lithium phosphate and conductive carbon material;

[0065] S5. The assembled battery was first activated for 2 cycles at a rate of 0.1C, and then cy...

PUM

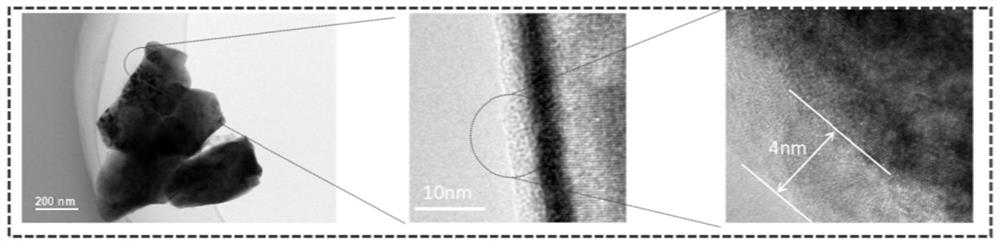

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com