Silicon oxide composite material and preparation method and application thereof

A composite material and silicon oxide technology, applied in electrochemical generators, electrical components, battery electrodes, etc., can solve the problems of low initial charge and discharge efficiency, poor cycle life, etc., to improve the transmission rate of electrons and lithium ions, negative electrode resistance Small, efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

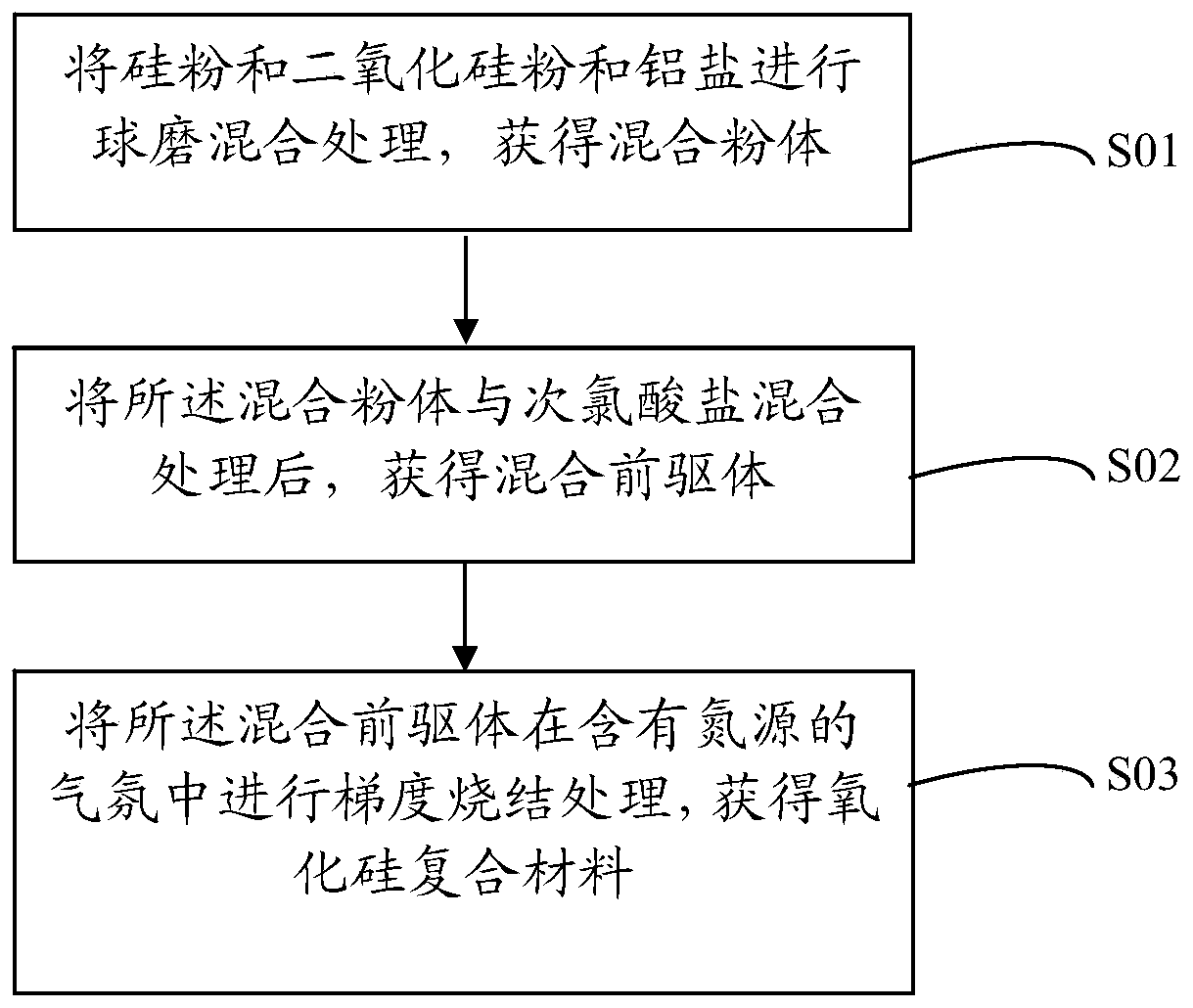

[0022] On the one hand, an embodiment of the present invention provides a method for preparing a silicon oxide composite material. The preparation method of the silicon oxide composite material comprises the following steps:

[0023] Step S01. Perform ball milling and mixing treatment of silicon powder, silicon dioxide powder and aluminum salt to obtain a mixed powder;

[0024] Step S02. After mixing the mixed powder and hypochlorite, a mixed precursor is obtained;

[0025] Step S03. The mixed precursor is subjected to gradient sintering in an atmosphere containing a nitrogen source to obtain a silicon oxide composite material.

[0026] Wherein, in the step S01, the silicon powder and the silicon dioxide powder are mixed by ball milling, on the one hand, the components are fully mixed, and on the other hand, the particles of the components are uniform and small, such as nanometer to sub- Microns. In one embodiment, the ball milling speed of the ball milling mixing treatment...

Embodiment 1

[0041] Embodiment 1 provides a silicon oxide composite material and a preparation method thereof. The silicon oxide composite material is prepared according to a method comprising the following steps:

[0042] S11: Mix and grind nano-sized silicon powder and sub-micron-sized silicon dioxide powder according to the molar ratio of 1:1, and put them into a ball mill for high-energy ball milling after they are evenly ground. After 5 hours, after ball milling, pass through a 100-150 mesh sieve to collect the material to obtain a mixed powder;

[0043] S12: Then add barium lithium hypochlorite with a mass percentage of 5% of the mixed powder to the mixed powder for regrinding; the speed of ball milling is set to 3000r / min, and the ball milling time is 3 hours to obtain a mixed precursor;

[0044] S13: The mixed precursor is sintered in a tube furnace using a gradient, and the specific operation is carried out in an ammonia atmosphere to obtain a silicon oxide composite material; wh...

Embodiment 2

[0046] Embodiment 1 provides a silicon oxide composite material and a preparation method thereof. The silicon oxide composite material is prepared according to a method comprising the following steps:

[0047] S11: Mix and grind nano-sized silicon powder and sub-micron-sized silicon dioxide powder according to the molar ratio of 1:1, and put them into a ball mill for high-energy ball milling after they are evenly ground. After 5 hours, after ball milling, pass through a 100-150 mesh sieve to collect the material to obtain a mixed powder;

[0048] S12: Then add sodium hypochlorite with a mass percentage of 5% of the mixed powder to the mixed powder for regrinding; the speed of ball milling is set to 3000r / min, and the ball milling time is 3 hours to obtain a mixed precursor;

[0049] S13: The mixed precursor is sintered in a tube furnace using a gradient, and the specific operation is carried out in an ammonia atmosphere to obtain a silicon oxide composite material; wherein, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com