Seaweed oil nano-pickering emulsion and oil powder stabilized by yolk protein peptide particles and preparation method and application thereof

A Pickering emulsion and protein peptide technology, which is applied in the application, skin care preparations, medical preparations containing active ingredients, etc., can solve the problems such as the inability to prepare nano-Pickering emulsion, achieve high water dispersibility and The effects of availability, good storage stability, and simple process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Preparation of egg yolk protein peptide: Disperse 60g of defatted egg yolk powder in 1800mL of deionized water, heat and stir in a water bath at 40°C for 0.5h, adjust the pH to 8.0 with 1M sodium hydroxide solution, add 0.6g of trypsin for 60min, and during the enzymolysis process Keep the pH constant. After the enzymatic hydrolysis, add 1M hydrochloric acid to adjust the pH to 7.0, inactivate the enzyme in a boiling water bath, cool, centrifuge at 8000rpm for 30min, take the supernatant for dialysis for 48h, and freeze-dry to obtain egg yolk protein peptide powder ;

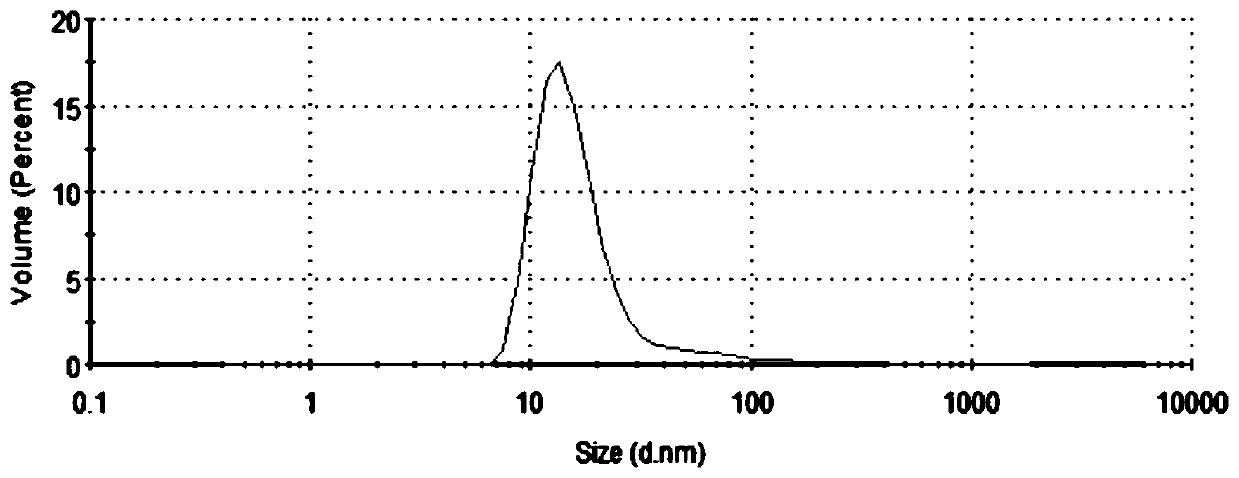

[0053] Preparation of nano-Pickering emulsion: yolk protein peptide powder was dissolved in 10 mM phosphate buffer (pH 7.0), stirred at room temperature for 1 h, and fully hydrated overnight at 4° C. to obtain 2 wt % yolk protein peptide solution. After adding 10mM phosphate buffer (pH7.0), different amounts of seaweed oil and different amounts of sunflower oil were added to obtain 0.5wt% egg yolk protein...

Embodiment 2

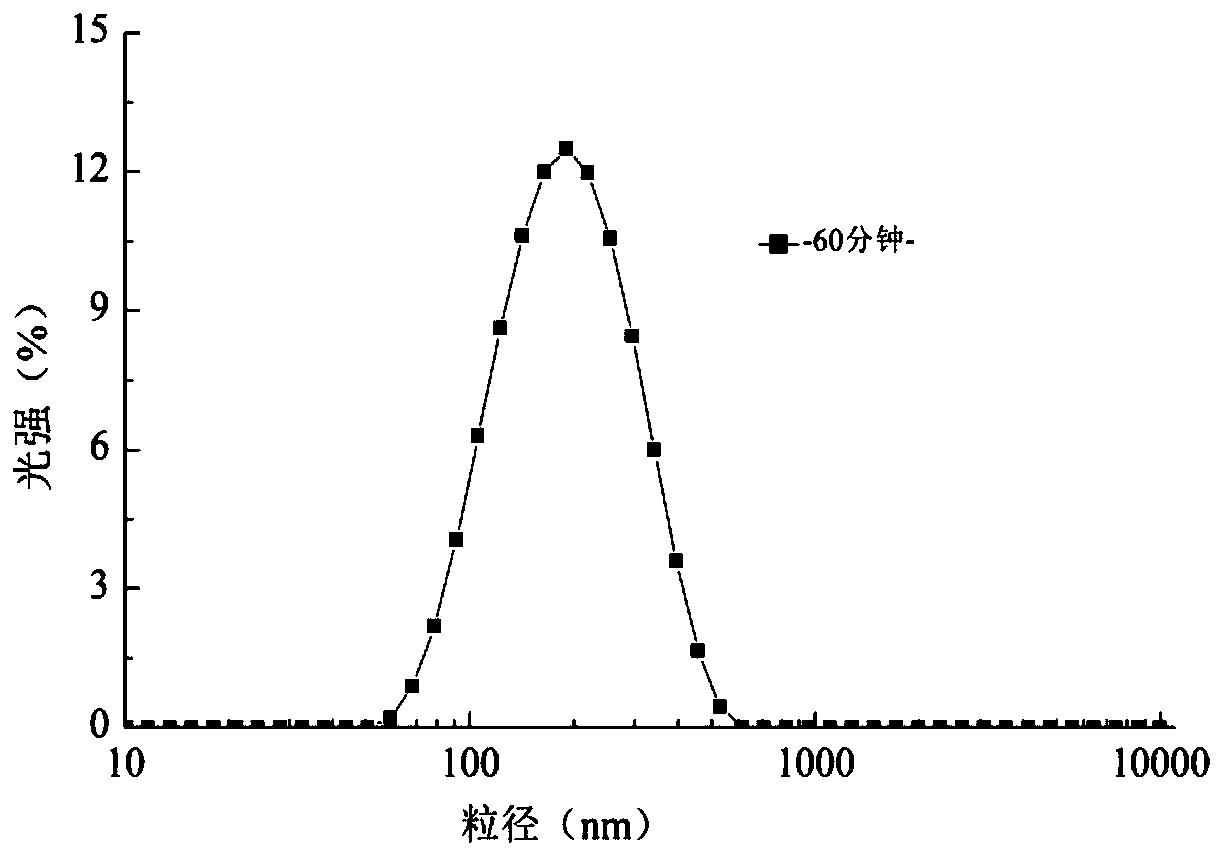

[0064] Preparation of egg yolk protein peptide: Disperse 50g of defatted egg yolk powder in 1500mL of deionized water, heat and stir in a water bath at 40°C for 0.5h, adjust the pH to 8.0 with 1M sodium hydroxide, add 0.5g of trypsin for enzymolysis, and keep Keep pH 8.0 constant, take samples at different times (10 / 30 / 60 / 120 / 180 / 300min), adjust pH to 7.0 with 1M hydrochloric acid, inactivate enzyme in boiling water bath, cool, centrifuge at 8000rpm for 30min, take supernatant Liquid dialysis for 48 hours, freeze-dried to obtain egg yolk protein peptide granule powder with different enzymatic hydrolysis time (10 / 30 / 60 / 120 / 180 / 300min);

[0065] Preparation of Nano-Pickering Emulsion: Egg Yolk Protein Peptide Powder Dissolved Egg Yolk Protein Peptide Powder in 10 mM Phosphate phosphate buffer (pH 7.0), Stirred at room temperature for 1 h, and Fully Hydrated Overnight at 4° C. to Obtain 2 wt % Egg Yolk Protein Peptide Solution. Add 10mM phosphate buffer (pH7.0) and seaweed oil to...

Embodiment 3

[0072] Preparation of egg yolk protein peptide: Disperse 50g of defatted egg yolk powder in 1700mL of deionized water, heat and stir in a 37°C water bath for 0.5h, adjust the pH to 8.0 with 1M sodium hydroxide solution, add 0.5g of trypsin for 60min, and during the enzymolysis process Keep the pH constant. After the enzymatic hydrolysis, add 1M hydrochloric acid to adjust the pH to 7.0, inactivate the enzyme in a boiling water bath, cool, centrifuge at 8000rpm for 30min, take the supernatant for dialysis for 48h, and freeze-dry to obtain egg yolk protein peptide powder ;

[0073] Preparation of Nano-Pickering Emulsion: Egg Yolk Protein Peptide Powder Dissolved Egg Yolk Protein Peptide Powder Dissolved in 10mM Phosphate phosphate buffer (pH 7.0), Stirred at Room Temperature for 1h, and Fully Hydrated at 4°C Overnight to Obtain 4wt% Egg Yolk Protein Peptide Solution. Add 10mM phosphate buffer (pH7.0) and seaweed oil to obtain 3wt% egg yolk protein peptide and 10wt% seaweed oil r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com