Low-sudden-release-rate semaglutide microspheres and preparation method thereof

A technology of semaglutide and microspheres, applied in the field of pharmaceutical preparations, can solve the problems of no obvious advantages of disease treatment cost, short half-life of exenatide, high dosage, to maintain the hypoglycemic effect, improve compliance and Quality of life, high encapsulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

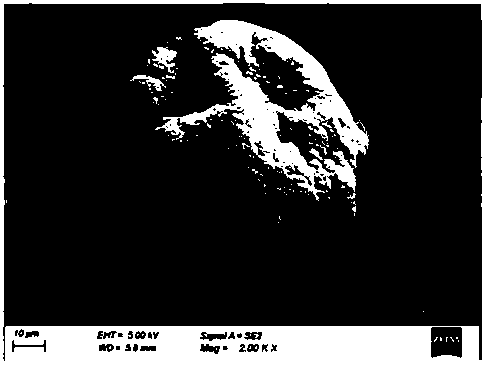

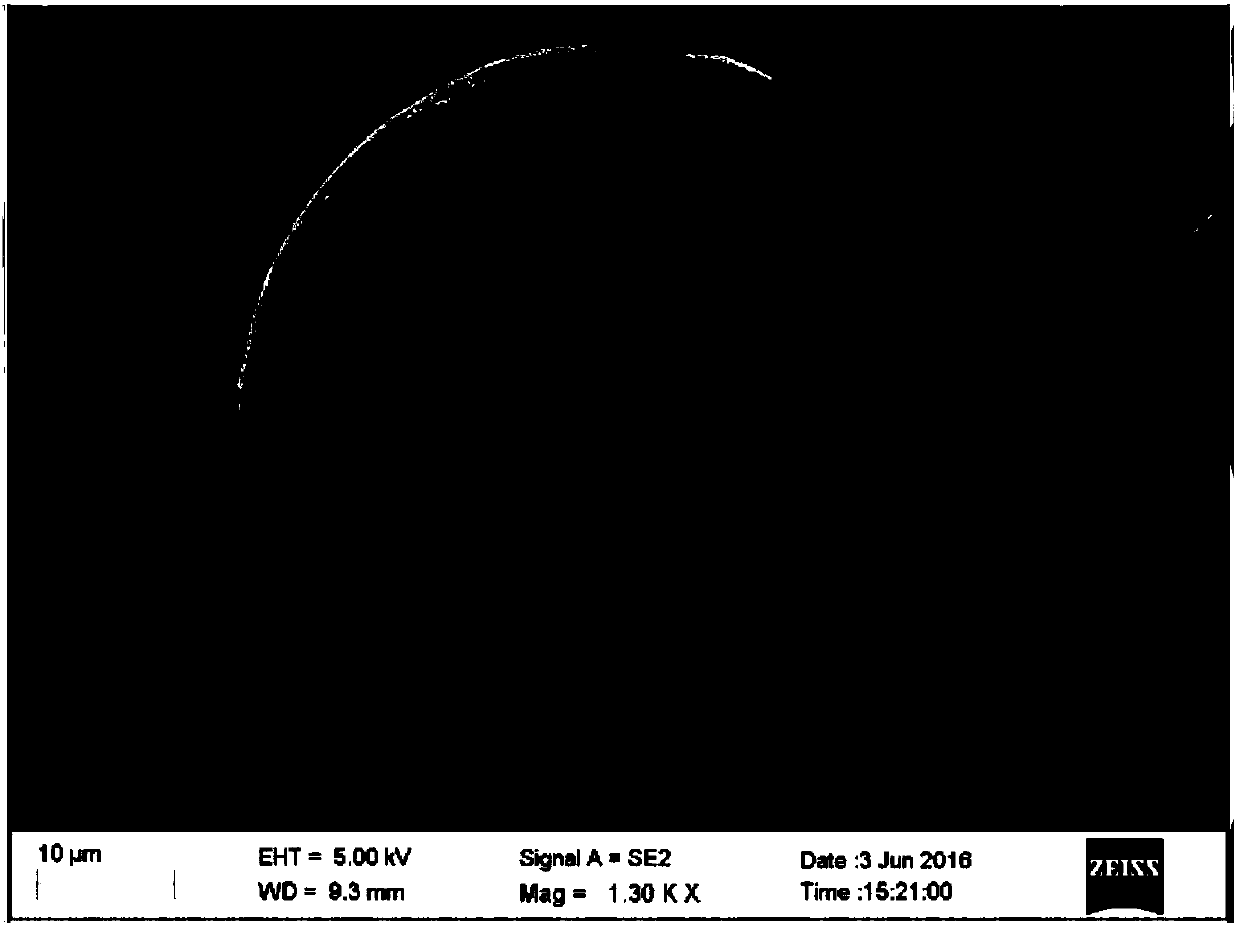

[0045] Example 1 Preparation of 10g scale 6% drug-loaded semaglutide microspheres

[0046] First, 9.1 g of glycolide-lactide copolymer (Evonik, Select 5050DLG 4A) was dissolved in 175.75g of dichloromethane to obtain an oil phase; 0.6g of semaglutide and 0.3g of sucrose were added to 7.0g of water for injection to dissolve to form a water phase; the water phase was added to the oil phase in an ice bath , obtain the emulsion through ultrasonic dispersion by ultrasonic cell breaker; 316g coagulant simethicone (Dow Corning 360Medical Fluid, 350CST) is added in the above-mentioned emulsion, while stirring, to obtain the coacervate phase containing microspheres in a soft state; then the coacervate phase Transfer to 3505g quenching solvent (n-heptane / dehydrated alcohol mixed solution, weight ratio 80:20) and harden, collect the microsphere after hardening afterwards, n-heptane / ethanol / water for injection (weight ratio 80:15: 5) Continue washing, finally collect, vacuum dry for dry...

Embodiment 2

[0047] Example 2 Preparation of 10g scale 8% drug loading semaglutide microspheres

[0048] First, 8.8 g of glycolide-lactide copolymer (Evonik, Select 5050DLG 4A) was dissolved in 167.2g of dichloromethane to obtain an oil phase; 0.8g of semaglutide and 0.4g of sucrose were added to 10.4g of water for injection to dissolve to form a water phase; the water phase was added to the oil phase on ice , the emulsion was obtained by ultrasonic dispersion by an ultrasonic cell disruptor; 290g coagulant simethicone (Dow Corning 360Medical Fluid, 350CST) was added to the above-mentioned emulsion, and stirred at the same time to obtain a coacervate phase containing microspheres in a soft state; Transfer to 3344g quenching solvent (n-heptane / dehydrated alcohol mixed solution, weight ratio 80:20) and harden, collect the microsphere after hardening again, n-heptane / ethanol / water for injection (weight ratio 80:15: 5) Continue washing, finally collect, vacuum dry for drying.

Embodiment 3

[0049] Example 3 Preparation of 10g-scale 12% drug-loaded semaglutide microspheres

[0050] First, 8.8 g of glycolide-lactide copolymer (Evonik, Select 5050DLG 4A) was dissolved in 167.2g of dichloromethane to obtain an oil phase; 1.2g of semaglutide and 0.4g of sucrose were added to 15.0g of water for injection to dissolve to form a water phase; the water phase was added to the oil phase in an ice bath , the emulsion was obtained by ultrasonic dispersion with an ultrasonic cell disruptor; 250g coagulant simethicone (Dow Corning 360Medical Fluid, 350CST) was added to the above emulsion at a uniform speed, and stirred at the same time to obtain a coagulated phase containing microspheres in a soft state; Phase transfer is carried out in 3344g quenching solvent (n-heptane / dehydrated alcohol mixed solution, weight ratio 80:20) and harden, collect the microsphere after hardening afterwards, n-heptane / ethanol / water for injection (weight ratio 80:15 :5) Continue washing, finally co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com