Silica-based germanomolybdate heteropolyacid catalyst for iodine recycling and preparation method thereof

A technology of iodine recovery and catalyst, which is applied in the field of catalysis, can solve the problems of high cost, low catalytic efficiency, and poor recovery, and achieve the effects of easy recovery, improved catalytic performance, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Catalyst preparation:

[0020] Put 1.000g of diatomaceous earth and 5ml of ureapropyltriethoxysilane solution in a dilute acid solution with a pH of 3 prepared by sulfuric acid, add 0.2g of Keggin type germanium molybdenum heteropolyacid, 1ml of octadecyl di Methyl hydroxyethylenediyl ammonium nitrate was magnetically stirred at room temperature for 24 hours, then ultrasonically oscillated for 1 hour, moved into a hydrothermal reaction kettle, and the reaction temperature was raised from room temperature to 150°C within 1 hour using a temperature-programmed oven, and the temperature was kept The temperature was 48 hours, and then the temperature was naturally lowered to room temperature, washed several times with ultrapure water and ethanol respectively, filtered, and dried for 12 hours to obtain samples for later use.

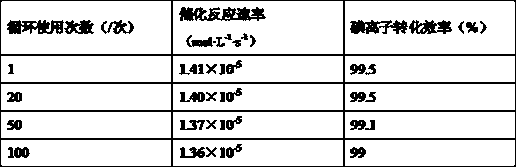

[0021] Catalyst evaluation:

[0022] (1) The catalyst embodiment:

[0023] Dissolve 1.6667g of potassium iodide in an appropriate amount of deionized...

Embodiment 2

[0037] Catalyst preparation:

[0038] Put 1.000g of diatomaceous earth and 5ml of ureapropyltriethoxysilane solution in a dilute acid solution with a pH of 3 prepared by sulfuric acid, add 0.2g of Keggin type germanium molybdenum heteropolyacid, 1ml of octadecyl di Ammonium methyl hydroxyethylenediyl ammonium nitrate, 0.04g ferrous sulfate, magnetically stirred at room temperature for 24 hours, then ultrasonically oscillated for 1 hour, moved into a hydrothermal reaction kettle, and the reaction temperature was raised from room temperature within 1 hour by using a temperature-programmed oven. to 150°C, keep the temperature for 48 hours, then cool down to room temperature naturally, rinse with ultrapure water and ethanol several times, filter, and dry for 12 hours to obtain samples for later use.

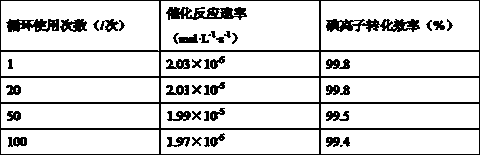

[0039] Catalyst evaluation:

[0040] Dissolve 1.6667g of potassium iodide in an appropriate amount of deionized water, transfer it to a 100mL volumetric flask, and adjust the volume...

Embodiment example 3

[0044] Catalyst preparation:

[0045] Put 1.000g of diatomaceous earth and 5ml of ureapropyltriethoxysilane solution in a dilute acid solution with a pH of 3 prepared by sulfuric acid, add 0.2g of Keggin type germanium molybdenum heteropolyacid, 1ml of octadecyl di Methyl hydroxyethylenediyl ammonium nitrate, 0.0456g zinc sulfate, magnetically stirred at room temperature for 24 hours, then ultrasonically oscillated for 1 hour, transferred to a hydrothermal reaction kettle, and the reaction temperature was raised from room temperature to 150°C, keep the temperature for 48 hours, then cool down to room temperature naturally, rinse with ultrapure water and ethanol several times, filter, and dry for 12 hours to obtain samples for later use.

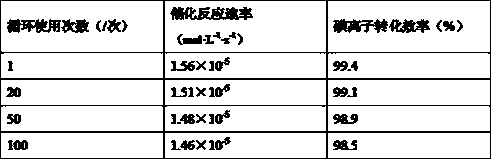

[0046] Catalyst evaluation:

[0047] Dissolve 1.6667g of potassium iodide in an appropriate amount of deionized water, transfer it to a 100mL volumetric flask, and adjust the volume to 0.01mol / L iodine solution, take 10mL of iodine solution,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com