Urushiol-modified phenolic resin, and preparation method and application thereof

A technology of phenolic resin and urushiol, which is applied in the field of adhesives to achieve the effects of good bonding performance, simple operation and lower temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1 Preparation of Urushiol Modified Phenolic Resin Adhesive D1

[0061] Preparation of a1 urushiol modified phenolic resin

[0062] Add 48.0 grams of phenol, 74.0 grams of 37wt% formaldehyde solution and 2.5 grams of strong ammonia water in a three-necked flask equipped with a stirrer, a reflux condenser, and a thermometer, heat up to 60°C, and react for 3 hours under stirring; Add 6.0 grams of urushiol and 2.8 grams of 37wt% formaldehyde solution therein, continue to stir and react at 60° C. for 2 hours, and distill off water under reduced pressure to obtain urushiol-modified phenolic resin.

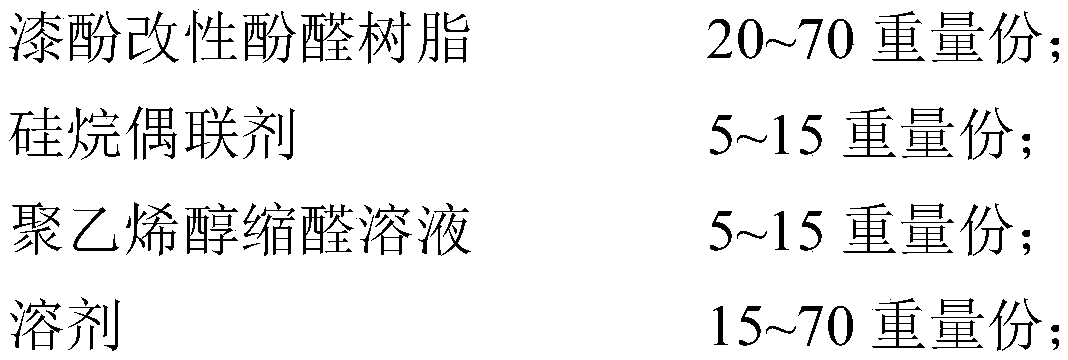

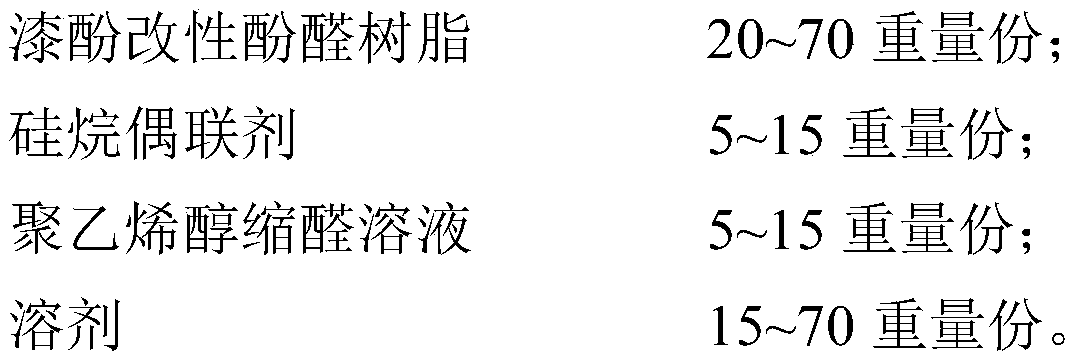

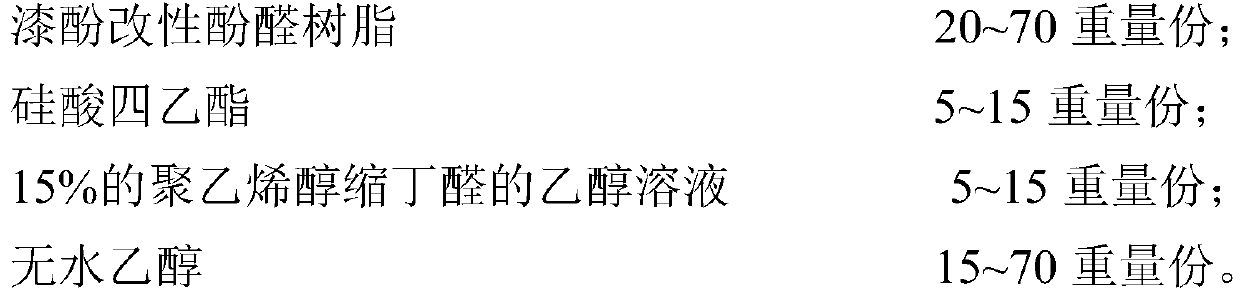

[0063] Preparation of b1 urushiol modified phenolic resin adhesive

[0064] In the there-necked flask equipped with mechanical stirrer and spherical condenser, add 50 grams of urushiol modified phenolic resin, 10 grams of tetraethyl silicate, 12 grams of 15wt% polyvinyl butyral ethanol solution and the raw material of 28 grams of absolute ethanol were mixed and stirre...

Embodiment 2

[0066] The preparation of embodiment 2 urushiol modified phenolic resin adhesive D2

[0067] Preparation of a1 urushiol modified phenolic resin

[0068] Add 39.7 grams of phenol, 61.2 grams of 37wt% formaldehyde solution and 2.5 grams of strong ammonia water in a three-necked flask equipped with a stirrer, a reflux condenser, and a thermometer, heat up to 80°C, and react for 2 hours under stirring; Add 3.6 grams of urushiol and 3.0 grams of 37wt% formaldehyde solution therein, continue to stir and react at 80° C. for 1 hour, and distill off water under reduced pressure to obtain urushiol-modified phenolic resin.

[0069] Preparation of b1 urushiol modified phenolic resin adhesive

[0070] In the there-necked flask equipped with mechanical stirrer and spherical condenser, add 70 grams of urushiol modified phenolic resin, 5 grams of tetraethyl silicate, 5 grams of 15wt% polyvinyl butyral ethanol solution and 20 grams of absolute ethanol were mixed and stirred evenly to obtain ...

Embodiment 3

[0072] Example 3 Preparation of urushiol-modified phenolic resin adhesive D3

[0073] Preparation of a1 urushiol modified phenolic resin

[0074] Add 41.6 grams of phenol, 65.8 grams of 37wt% formaldehyde solution and 2.8 grams of strong ammonia water in a three-necked flask equipped with a stirrer, a reflux condenser, and a thermometer, heat up to 90° C., and react for 1 hour under stirring; Add 12.4 grams of urushiol and 5.2 grams of 37wt% formaldehyde solution therein, continue to stir and react at 90° C. for 0.3 hours, and distill off water under reduced pressure to obtain urushiol-modified phenolic resin.

[0075] Preparation of b1 urushiol modified phenolic resin adhesive

[0076] In the there-necked flask equipped with mechanical stirrer and spherical condenser, add 20 grams of urushiol modified phenolic resin, 15 grams of tetraethyl silicate, 15 grams of 15wt% polyvinyl butyral ethanol solution and the raw material of 50 grams of dehydrated alcohol, mix and stir even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com