Battery coating film slurry, battery diaphragm, secondary battery and preparation method thereof

A technology of coating film and slurry, which is applied to battery components, separators/films/diaphragms/spacers, circuits, etc., and can solve problems such as large swelling, large internal resistance of batteries, and poor cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

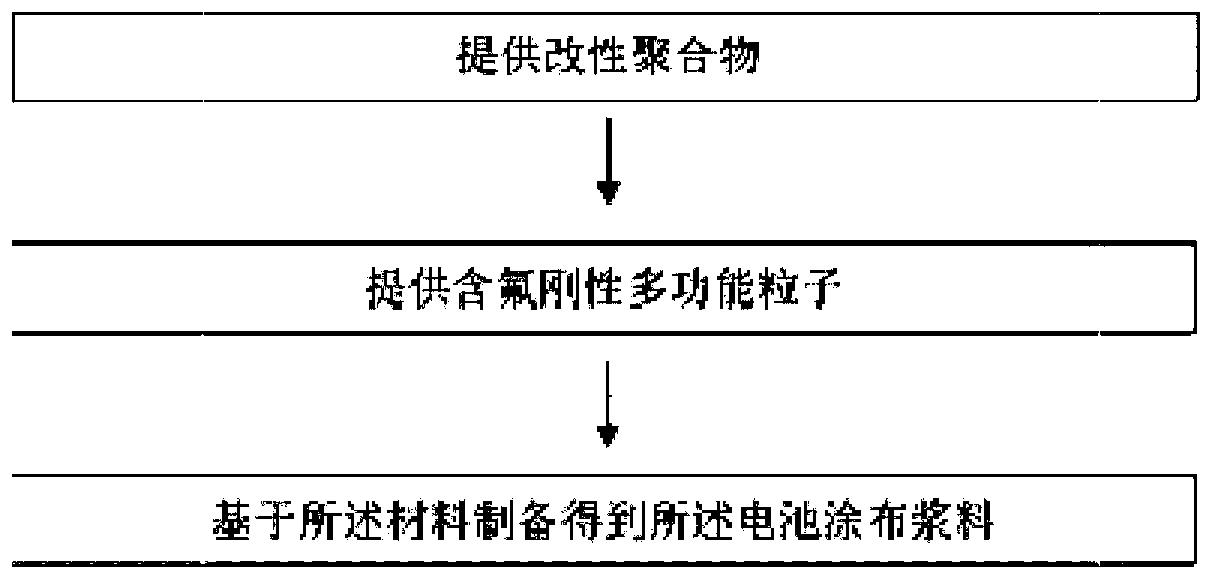

[0101] A preparation method of battery coating film slurry, comprising the steps of:

[0102] 1. Provide modified polymers;

[0103] 2. Provide inorganic fillers;

[0104] 3. Prepare battery coating film slurry based on the materials provided above.

[0105] The technological process of preparation method sees appendix figure 1 .

[0106] The modified polymer preparation method of step 1, its specific steps are:

[0107] (1) Hexadecyldimethylphosphoric acid was dissolved in ice water to prepare a solution, and anilinomethyltriethoxysilane was added and ultrasonically dissolved at 5°C for 0.5-1 hour.

[0108] Various materials are counted according to mass parts, and the mass parts of cetyl dimethyl phosphoric acid is 5 parts, and the mass parts of ice water is 75 parts, and the feeding amount of anilinomethyltriethoxysilane is the same as that of hexadecane The molar weight of base dimethyl phosphoric acid is the same;

[0109] (2) Stir in the solution obtained in step (...

Embodiment 2

[0175] A preparation method of battery coating film slurry, comprising the steps of:

[0176] 1. Provide modified polymers;

[0177] 2. Provide inorganic fillers;

[0178] 3. Prepare battery coating film slurry based on the materials provided above.

[0179] The modified polymer preparation method of step 1, its specific steps are:

[0180] (1) Diethyl octadecyl phosphate was dissolved in ice water to form a solution, and anilinomethyltriethoxysilane was added and ultrasonically dissolved at 5°C for 0.5-1 hour.

[0181] Various materials are counted according to the mass parts, the mass parts of octadecyl diethyl phosphate is 5 parts, the mass parts of ice water is 75 parts, the feeding amount of anilinomethyltriethoxysilane and octadecyl Diethyl phosphate has the same molar mass

[0182] (2) Stir in the solution obtained in step (1), and add 2 to 3 drops of tertiary amine catalysts to promote the hydrolysis and condensation of anilinomethyltriethoxysilane. After hydrolysi...

Embodiment 3

[0198] The invention provides a method for preparing battery coating film slurry, comprising the following steps:

[0199] 1. Provide modified polymers;

[0200] 2. Provide inorganic fillers;

[0201] 3. Prepare battery coating film slurry based on the materials provided above.

[0202] The modified polymer preparation method of step 1, its specific steps are:

[0203] (1) Hexadecyldimethylphosphoric acid was dissolved in ice water to prepare a solution, and anilinomethyltriethoxysilane was added and ultrasonically dissolved at 5°C for 0.5-1 hour.

[0204] Various materials are calculated according to the mass parts, the mass parts of cetyl dimethyl phosphoric acid is 10 parts, the mass parts of ice water is 100 parts, the feeding amount of anilinomethyltriethoxysilane is the same as that of cetyl The same molar amount of dimethylphosphoric acid

[0205] (2) Stir in the solution obtained in step (1), and add 2 to 3 drops of tertiary amine catalysts to promote the hydrolysi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com