Carbon-supported platinum alloy powder and preparation method thereof

A technology of alloy powder and carbon-supported platinum, which is applied in nanotechnology for materials and surface science, structural parts, electrical components, etc., can solve problems such as complex procedures, long preparation time, and inapplicability of multi-component platinum alloy catalysts. The effect of broad application prospects and huge market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

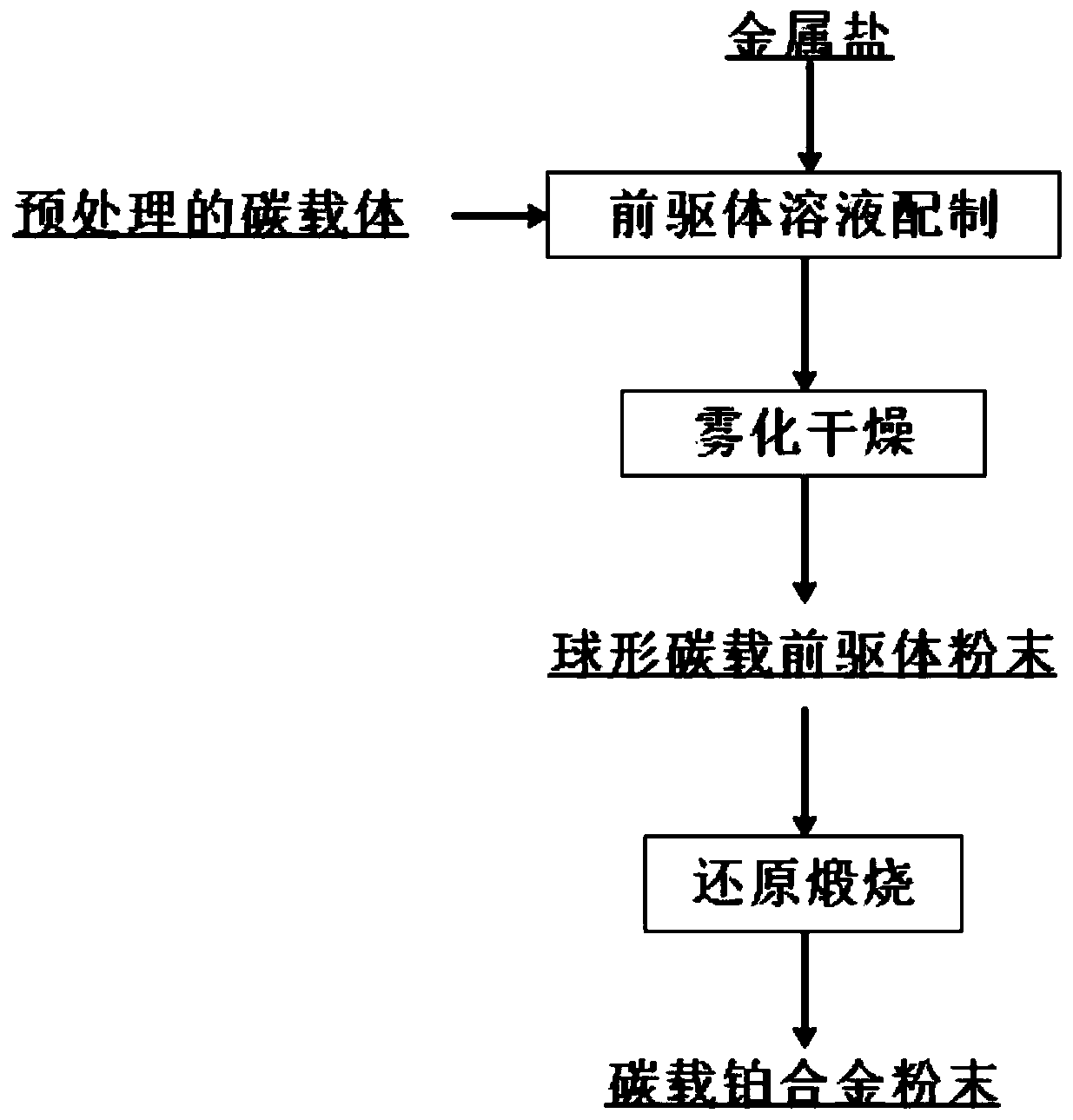

[0026] The carbon-supported platinum alloy powder of the present invention is prepared through the following steps:

[0027] (1) Liquid-phase precursor preparation process: Dissolve ammonium chloroplatinate, cobalt oxalate, nickel chloride, and ammonium chlororuthenate in water at an atomic ratio of Pt:Co:Ni:Ru=3:1:1:1 , add commercial XC 72 as a carrier, continue to stir and mix thoroughly and perform ultrasonic treatment to obtain a mixture of carbon black and precursor solution.

[0028] (2) Atomization drying process: using the atomization drying method, the control liquid flow rate is 8.0ml / min, the atomization pressure is 0.5MPa, the inlet temperature is 180°C, and the hot air flow rate is 10.0L / min. Metal salt spherical particles with a particle size of about 1-4 μm;

[0029] (3) Powder reduction calcination process: calcining the carbon-supported precursor powder at high temperature in a hydrogen atmosphere to obtain spherical carbon-supported platinum alloy powder. ...

Embodiment 2

[0031] The difference from Example 1 is that the carbon black has been pretreated: add an acetone solution with 2 times the carbon volume to a certain amount of XC-72 carbon powder, stir at room temperature for 3h, filter and wash with secondary water, and then use Vacuum drying at 50°C; add the dried sample to an appropriate amount of 10% HNO 3 and 30%H 2 o 2 Mixed solution (volume ratio HNO 3 :H 2 o 2 =2:1) Reflux at 60°C for 5h, filter and wash with secondary water until neutral, then dry in vacuum at 50°C; grind the dried carbon material sample to obtain a modified carbon support.

Embodiment 3

[0033] The difference from Example 2 is that in the reduction calcination process: the carbon-supported precursor powder is 2 The atmosphere was raised from room temperature to 410°C, and then 2 At 410°C in air for 1h, then in N 2 The atmosphere is cooled with the furnace, and the entire calcination process is carried out under the protection of the atmosphere.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com