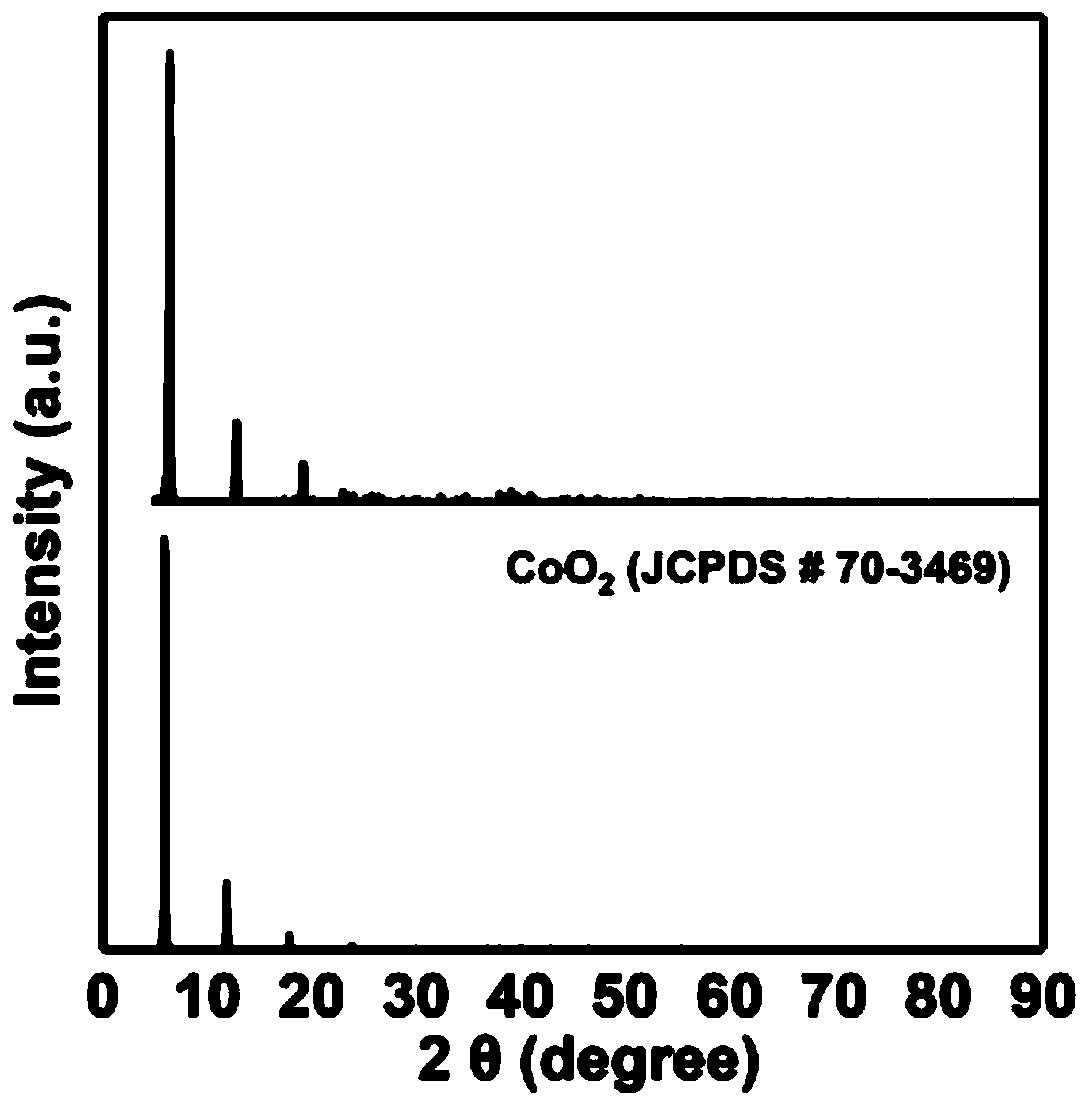

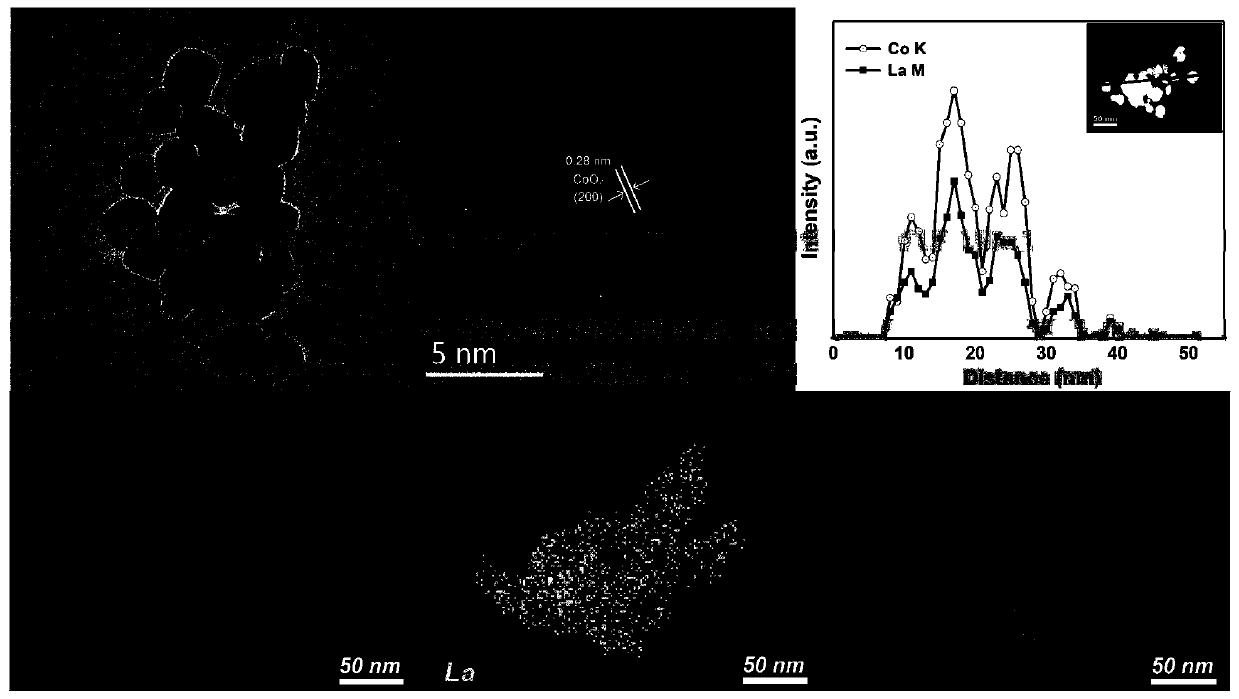

Controllable synthetic lanthanum-doped cobalt oxide nanosheet and preparation method and application thereof

A cobalt oxide and nanosheet technology, applied in the nano field, can solve the problems of limiting the commercial application of catalysts, high catalyst overpotential, slow kinetics, etc., and achieve the effects of high yield, low reaction temperature, and efficient catalysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] At room temperature, weigh Co(NO 3 ) 2 ·6H 2 O 2.0mmol, La(NO 3 ) 3 ·6H 2 O 0.2mmol powder and 30ml distilled water were added to dry and clean beaker 1; suberic acid 6.0mmol, sodium hydroxide 15.0mmol powder and 30ml distilled water were added to dry and clean beaker 2. Sonicate and stir until completely dissolved to obtain solution A in beaker 1 and solution B in beaker 2.

[0037] The solution in beaker 1 was transferred to beaker 2, and mechanically stirred for 3 hours under a water bath at 50° C. to obtain a pre-reaction solution. Pipet 35ml of the pre-reaction solution with a pipette gun, put it into a polytetrafluoroethylene autoclave, put it into an oven, and directly raise the temperature to 195°C for 18 hours. After the reactor was naturally cooled to room temperature, it was washed three times with absolute ethanol and distilled water, and the solid was separated by centrifugation. The gray-brown product was obtained after washing the solid, which was ...

Embodiment 2

[0041] At room temperature, weigh Co(NO 3 ) 2 ·6H 2 O 2.0mmol, La(NO 3 ) 3 ·6H 2 O 0.1mmol powder and 30ml distilled water were added to dry and clean beaker 1; suberic acid 6.0mmol, sodium hydroxide 15.0mmol powder and 30ml distilled water were added to dry and clean beaker 2. Sonicate and stir until completely dissolved to obtain solution A in beaker 1 and solution B in beaker 2.

[0042] The solution in beaker 1 was transferred to beaker 2, and mechanically stirred for 3 hours under a water bath at 30° C. to obtain a pre-reaction solution. Pipet 35ml of the pre-reaction solution with a pipette gun, put it into a polytetrafluoroethylene high-pressure reactor, put it into an oven, and directly raise the temperature and keep it at 195°C for 18h. After the reactor was naturally cooled to room temperature, it was washed three times with absolute ethanol and distilled water, and the solid was separated by centrifugation. The gray-brown product was obtained after washing th...

Embodiment 3

[0044] In the three-electrode system, the electrochemical properties of the samples were tested by cyclic voltammetry and polarization curve method. The specific process is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com