Oxygen electrode bifunctional catalyst, preparation method and application

A bifunctional catalyst, oxygen electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of OER performance ORR active component ORR performance reduction, etc., and achieve the effect of improving electrocatalytic performance, reducing usage, and high dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the oxygen electrode bifunctional catalyst of the present invention, firstly, the carbon carrier is used as a reducing agent, and the iridium salt is reduced at a high temperature to obtain elemental iridium, that is, the elemental iridium is loaded on the surface of the carbon carrier to form Ir / C; and then the Ir / C As a carrier, ethylene glycol is used as a reducing agent, and Ir / C is mixed with platinum salt, cobalt salt and tungsten salt, and reacted at a constant temperature in an oil bath to realize the precipitation of platinum, cobalt, and tungsten on Ir / C, and the catalyst PtCoW- Ir / C.

[0039] The above-mentioned carbon carrier is graphene, carbon black, carbon nanotube, graphitized carbon or porous carbon; the iridium salt is iridium tetrachloride.

[0040] The above-mentioned platinum salt is chloroplatinic acid, the cobalt salt is cobalt chloride, and the tungsten salt is tungsten carbonyl

[0041] The preparation method of the oxyg...

Embodiment 1

[0051] Preparation of PtCoW80-Ir40 / CB Bifunctional Catalyst

[0052] (1) Take 50 mg of carbon black (CB) as a carrier, ultrasonically disperse it in 20 mL of water: ethanol with a ratio of 1: 1 for 30 min, and then add IrCl 4 solution (0.1 mmol Ir) and 10 mg dopamine, and continue to sonicate for half an hour until they are evenly mixed. Then it was stirred by magnetic force for 12h, and then dried in an oven at 70°C.

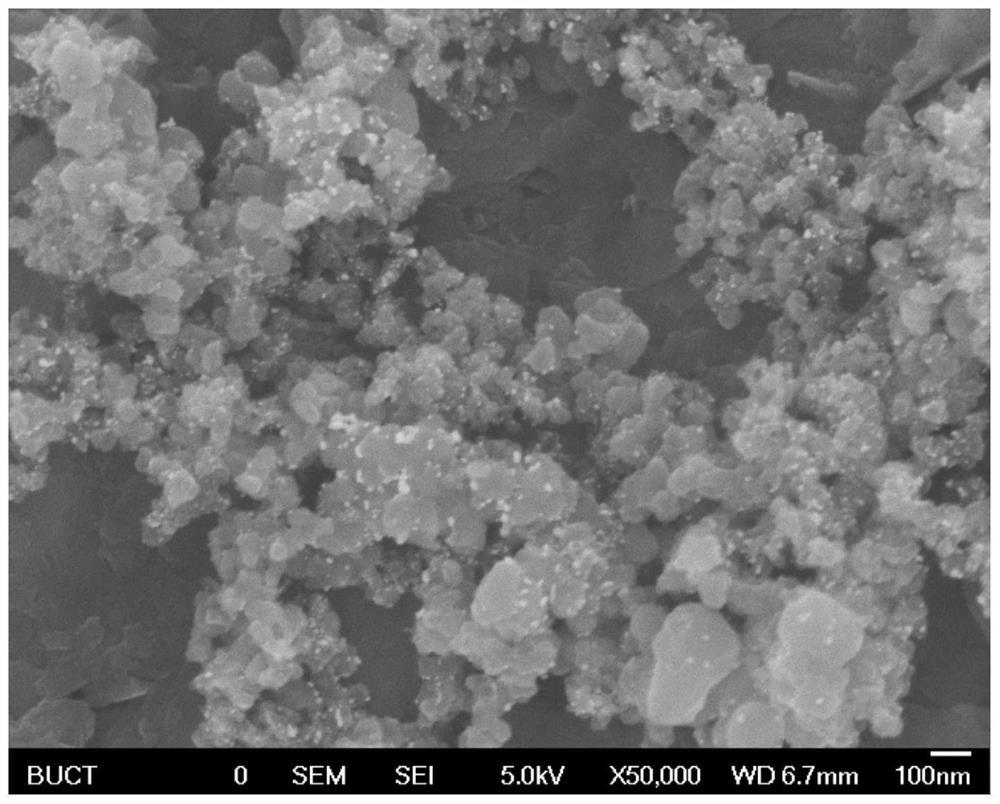

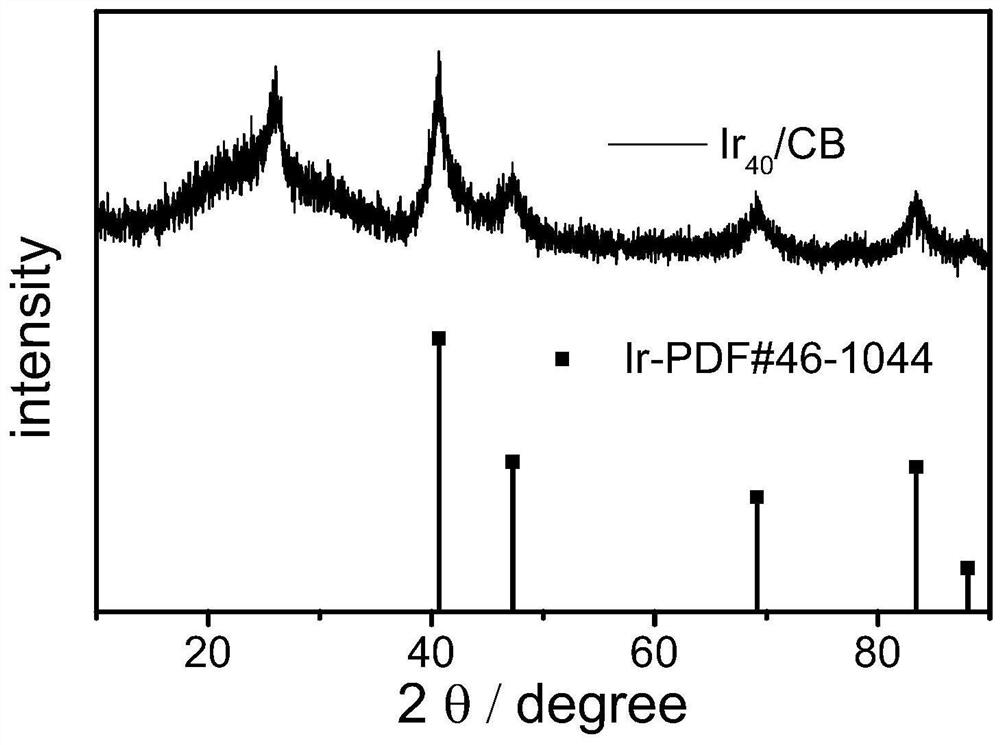

[0053] (2) Grind the dried sample in an agate mortar for several minutes. Then at 900°C, the heating rate is 5°C / min, calcined in Ar atmosphere for 1h, and Ir is reduced by using carbon at high temperature. An OER catalyst with excellent performance can be obtained, which is marked as Ir40 / CB.

[0054] (3) Weigh 25.7mg of Ir40 / CB, add 38mL of ethylene glycol, and then put it into an ultrasonic machine to sonicate evenly, and then add 9.3mL of 0.01mM H 2 PtCl 6 Ethylene glycol solution, 0.31mL 0.1mMCoCl 2 Ethylene glycol solution and 1.1mg W(CO) 6 , 1.2 m...

Embodiment 2

[0057] Preparation of PtCoW80-Ir80 / CB Bifunctional Catalyst

[0058] (1) Take 50 mg of carbon black (CB) as a carrier, ultrasonically disperse it in 20 mL of water: ethanol with a ratio of 1: 1 for 30 min, and then add IrCl 4 solution (0.2 mmol Ir) and 10 mg dopamine, and continue to sonicate for half an hour until they are evenly mixed. Then it was stirred by magnetic force for 12h, and then dried in an oven at 70°C.

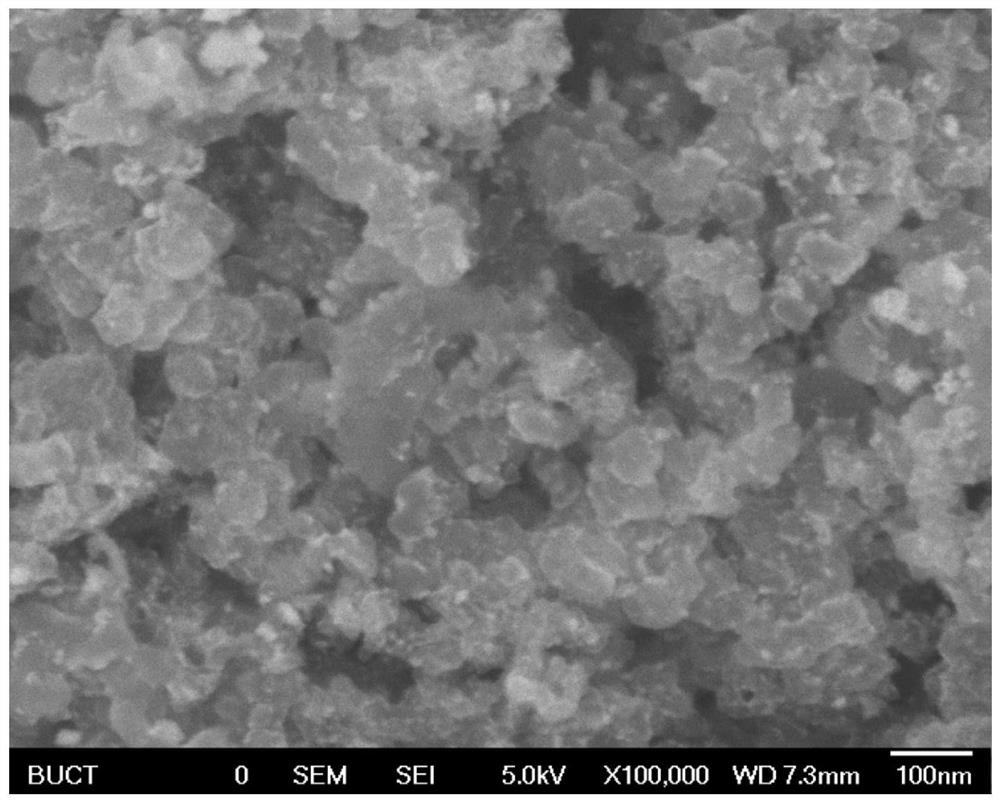

[0059] (2) Grind the dried sample in an agate mortar for several minutes. Then, at 800°C, the heating rate was 5°C / min, and calcined in Ar atmosphere for 1h, and Ir was reduced by using carbon at high temperature. An OER catalyst with excellent performance can be obtained, which is marked as Ir80 / CB.

[0060] (3) Weigh 25.7mg of Ir80 / CB, add 38mL of ethylene glycol, and then put it into an ultrasonic machine to sonicate evenly, and then add 9.3mL of 0.01mM H 2 PtCl 6 Ethylene glycol solution, 0.31mL 0.1mMCoCl 2 Ethylene glycol solution and 1.1mg W(CO) 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com