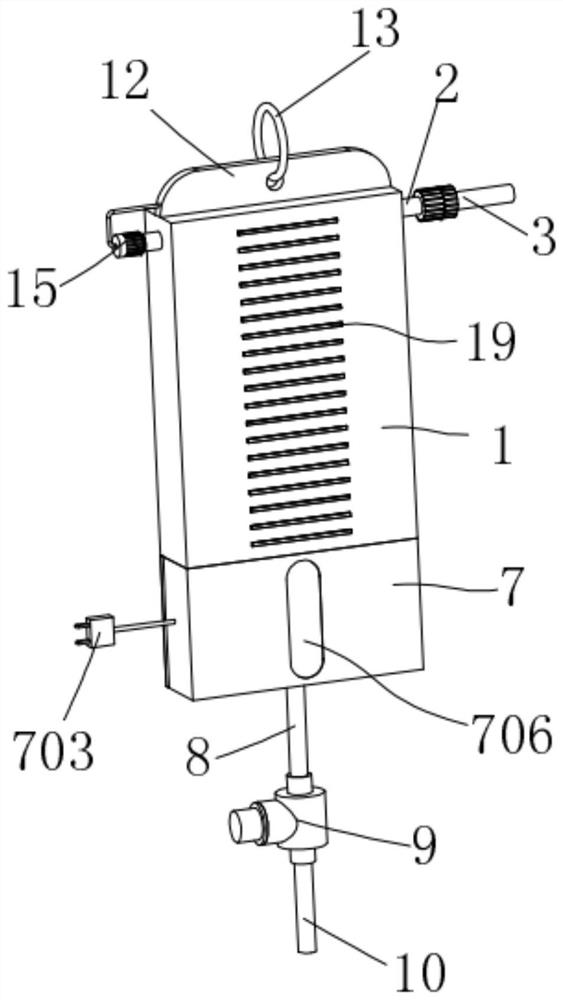

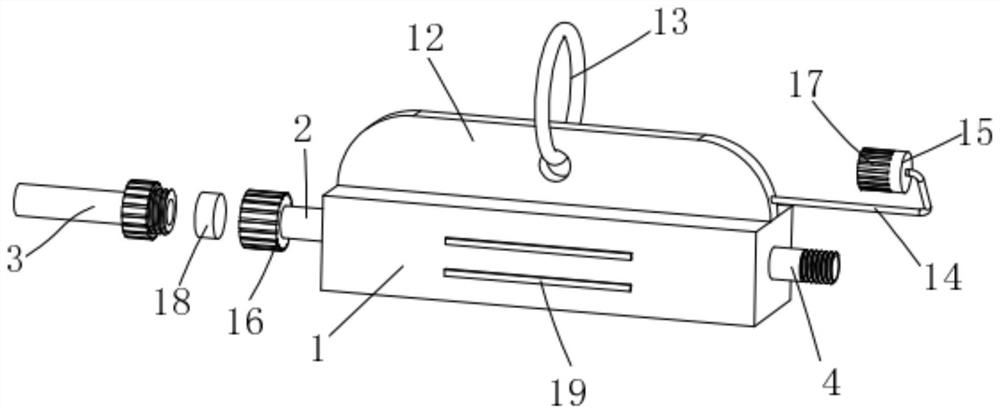

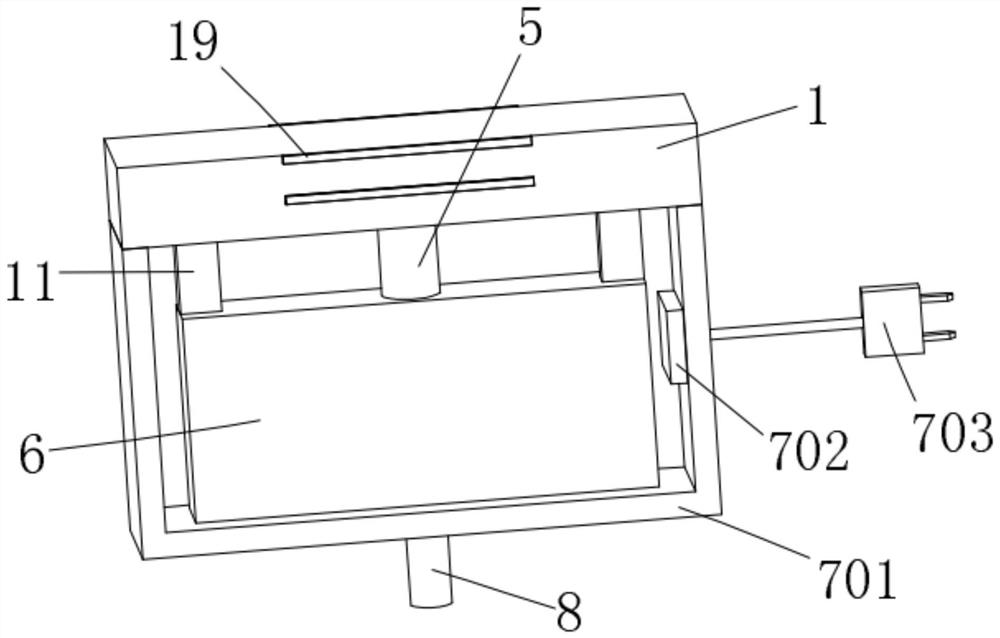

An intelligent enteral nutrition infusion bag

A technology of enteral nutrition and infusion bags, which is applied in the field of infusion bags, can solve problems such as slow infusion speed, film infusion quality, and patient discomfort, and achieve the effects of preventing bacterial contamination, improving antibacterial ability, and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0068] The difference from Example 1 is that the surfaces of the first liquid storage bag 1 and the second liquid storage bag 6 are coated with an antibacterial layer, and the antibacterial layer is prepared by the following method:

[0069] Take the following raw materials and weigh them by weight: 3 parts of styrene-acrylic emulsion, 4 parts of acrylate emulsion, 5 parts of dodecylbenzenesulfonic acid, 6 parts of ethanolamine, 7 parts of sodium citrate, 8 parts of protease, 9 parts of methyl benzyl ammonium chloride, 10 parts of fatty alcohol polyoxyethylene ether, 13 parts of silicone defoamer, 20 parts of bentonite binder, 90 parts of deionized water;

[0070] S1, material preparation: first weigh the above-mentioned raw materials;

[0071] S2. Preliminary mixing: first add deionized water to the digital display constant temperature magnetic stirrer, then add styrene-acrylic emulsion, acrylate emulsion, dodecylbenzenesulfonic acid, ethanolamine, sodium citrate, and proteas...

Embodiment 3

[0080] The difference from Example 2 is the preparation of the antibacterial layer, and its specific preparation method is as follows:

[0081] Take the following raw materials and weigh them by weight: 4 parts of styrene-acrylic emulsion, 5 parts of acrylate emulsion, 6 parts of dodecylbenzenesulfonic acid, 7 parts of ethanolamine, 8 parts of sodium citrate, 9 parts of protease, 10 parts of methyl benzyl ammonium chloride, 12 parts of fatty alcohol polyoxyethylene ether, 14 parts of silicone defoamer, 24 parts of bentonite binder, 100 parts of deionized water;

[0082] S1, material preparation: first weigh the above-mentioned raw materials;

[0083] S2. Preliminary mixing: first add deionized water to the digital display constant temperature magnetic stirrer, then add styrene-acrylic emulsion, acrylate emulsion, dodecylbenzenesulfonic acid, ethanolamine, sodium citrate, and protease to the digital display constant temperature In the magnetic stirrer, stir and mix the materials...

Embodiment 4

[0092] The difference from Example 2 is the preparation of the antibacterial layer, and its specific preparation method is as follows:

[0093] Take the following raw materials and weigh them by weight: 5 parts of styrene-acrylic emulsion, 6 parts of acrylate emulsion, 7 parts of dodecylbenzenesulfonic acid, 8 parts of ethanolamine, 9 parts of sodium citrate, 10 parts of protease, 11 parts of methyl benzyl ammonium chloride, 13 parts of fatty alcohol polyoxyethylene ether, 15 parts of silicone defoamer, 26 parts of bentonite binder, 110 parts of deionized water;

[0094] S1, material preparation: first weigh the above-mentioned raw materials;

[0095] S2. Preliminary mixing: first add deionized water to the digital display constant temperature magnetic stirrer, then add styrene-acrylic emulsion, acrylate emulsion, dodecylbenzenesulfonic acid, ethanolamine, sodium citrate, and protease to the digital display constant temperature In the magnetic stirrer, stir and mix the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com