A preparation method of porous carbon-carbon nanotube hollow fiber membrane that generates hydroxyl radicals under electrochemical strengthening

A technology of carbon nanotubes and porous carbon, which is applied in the field of preparation of porous carbon-carbon nanotube hollow fiber membranes, can solve the problems of inability to form a skeleton, unfavorable practical application, and low mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

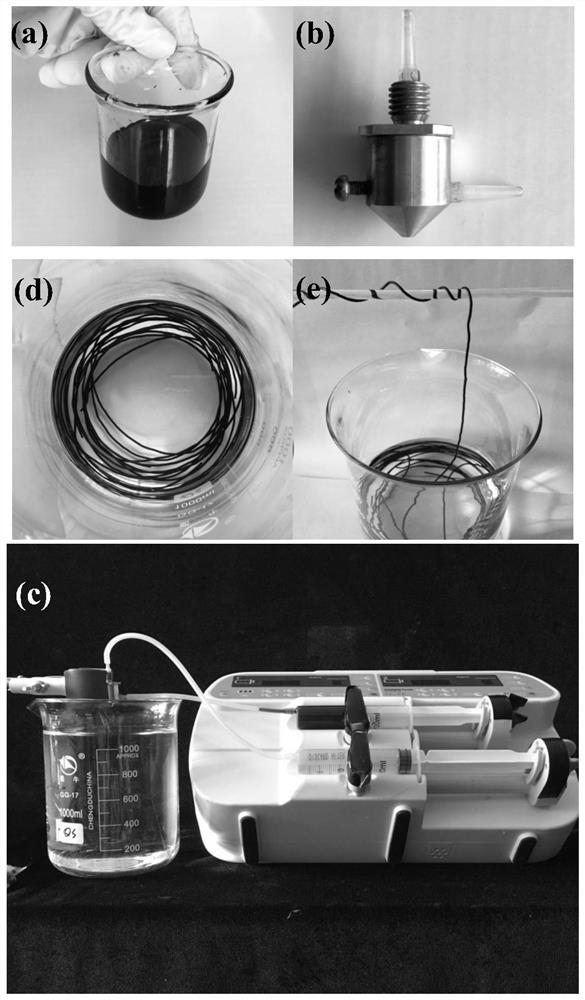

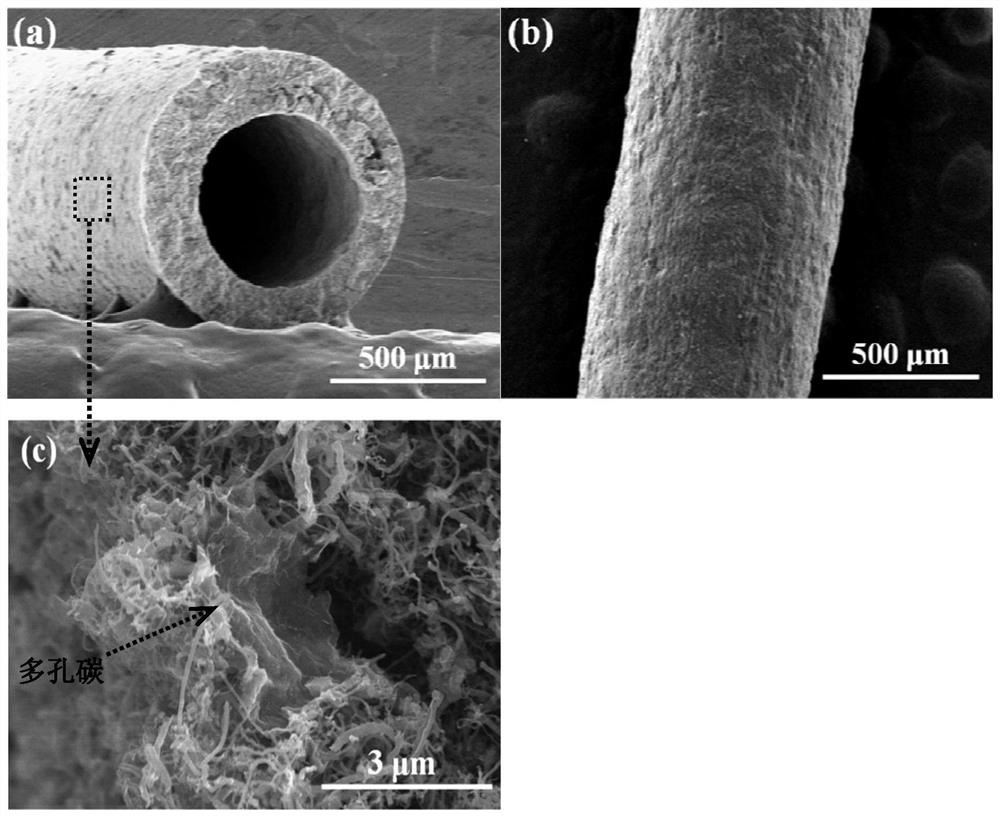

[0042] The preparation method of porous carbon-carbon nanotube hollow fiber membrane is as follows:

[0043]Step 1: Weigh 7.4350g of zinc nitrate hexahydrate and pour it into 500ml of methanol; weigh another 2.0520g of 2-methylimidazole and 3.2675g of triethylamine and dissolve them in new 500ml of methanol. Mix well. After the mixed solution was continued to be sonicated for 30 min, the mixed solution was left to stand for 4 hours to obtain 2-dimensional nanosheets. The desired Zif-8 was obtained by suction filtration and drying.

[0044] Step 2: Weigh a certain mass (2-4g) of Zif-8 in a tube furnace, program the temperature to 1000°C, and calcinate for 2 hours, the protective gas is H 2 and N 2 Mixed gas (volume ratio 1:1), after calcination and cooling to room temperature, the desired porous carbon can be obtained.

[0045] Step 3: Put 1 g of carbon nanotubes in a mixed acid solution of concentrated nitric acid and concentrated sulfuric acid (volume ratio 1:3), heat to ...

Embodiment 2

[0052] Using the patent application with publication number CN109384307A: A construction principle of a membrane bioreactor with electrochemically strengthened carbon nanotube hollow fiber membrane as the separation unit to build an experimental filtration device, replace the carbon nanotube hollow fiber membrane in the membrane bioreactor The porous carbon-carbon nanotube hollow fiber membrane prepared by the method of Example 1 is used as the anode, and the titanium mesh is used as the cathode, and the experimental filter device does not need to use activated sludge. Other parts and connections in the device refer to CN109384307A . Among them, the porous carbon-carbon nanotube hollow fiber membrane module in the experimental filtration device is a membrane module formed by connecting six porous carbon-carbon nanotube hollow fiber membranes in parallel, and the porous carbon-carbon nanotube hollow fiber membrane is used as the cathode. Negative electrode, and the effective ar...

Embodiment 3

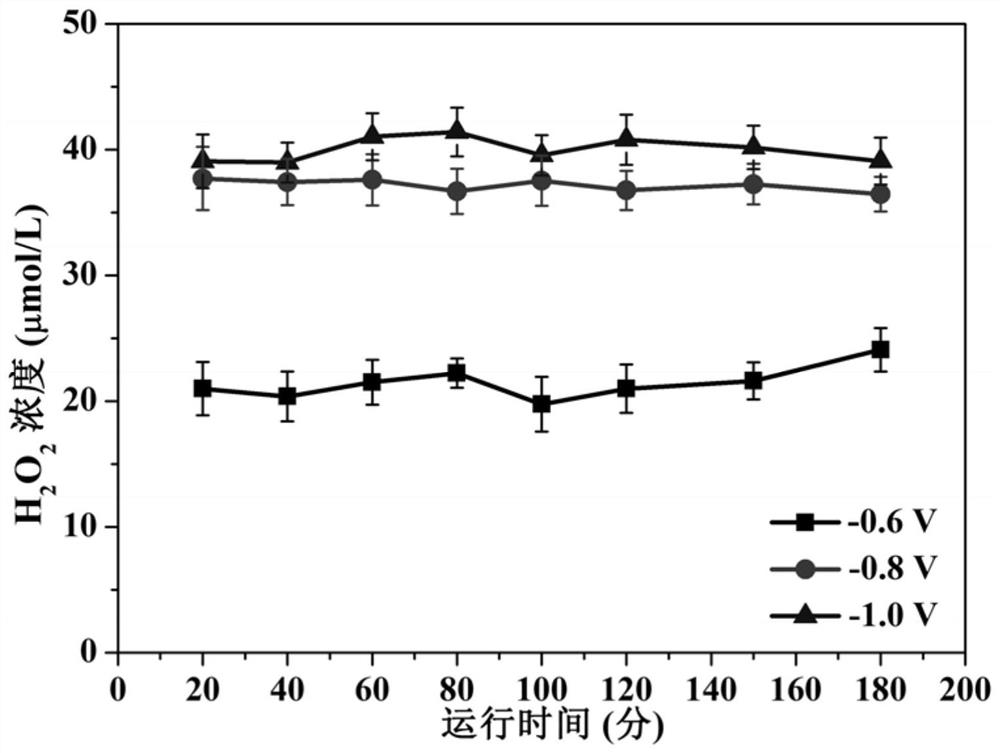

[0056] Utilize the filtration device of embodiment 2, test the generation of hydroxyl free radical under the effect of porous carbon-carbon nanotube hollow fiber membrane prepared in electrochemical strengthening embodiment 1:

[0057] Under the condition of sufficient dissolved oxygen exposure in the system, the effects of iron ions (0.2mM, from ferrous sulfate) and electrification on the production of hydroxyl radicals were investigated respectively. The result is as Figure 4 As shown, four peak signals with an intensity ratio of 1:2:2:1 appeared in the electrically assisted (-0.8V) porous carbon-carbon nanotube hollow fiber membrane, which is similar to a typical free radical spin adduct . Meanwhile, no typical peak signal appeared on the porous carbon-carbon nanotube hollow fiber membrane without electrical assistance, which indicated that OH was generated under electrical assistance. Furthermore, in the absence of Fe 2+ In the case of electrically assisted porous carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com