Manufacturing method of graphene oxide super-thermal conductive aluminum-based copper clad laminate

A technology of aluminum-based copper-clad laminates and manufacturing methods, applied in chemical instruments and methods, epoxy resin glue, adhesive types, etc., can solve high manufacturing costs, difficult processing, heat resistance, thermal conductivity, voltage resistance and Poor flexibility and other problems, to achieve stable and reliable effect, simple and easy method, scientific and reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

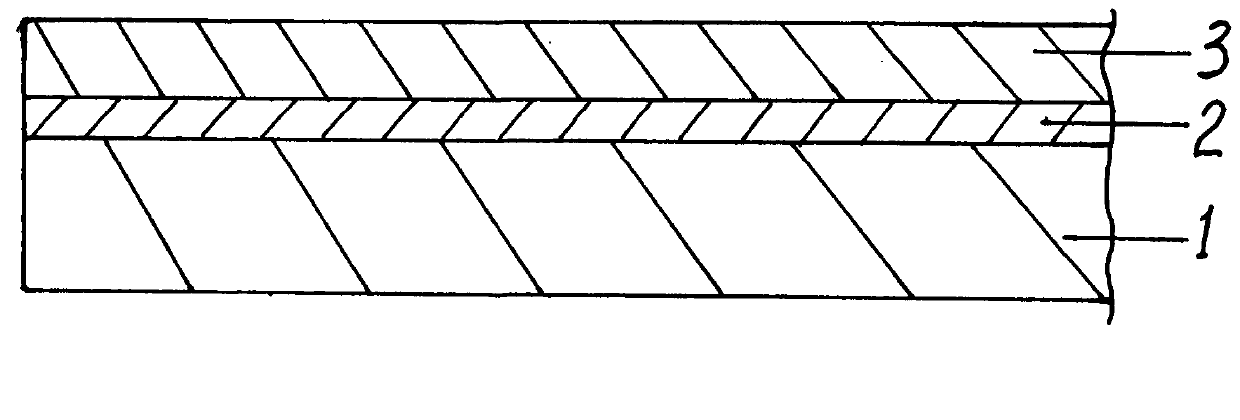

[0030] The following is a detailed description of the new product "graphene oxide superconducting heat-conducting aluminum-based copper-clad laminate" in the present invention in conjunction with the drawings of the description. As attached to the manual figure 1 Shown:

[0031] A graphene oxide superconducting heat-conducting aluminum-based copper-clad laminate is composed of an aluminum substrate 1, a non-conductive superconducting heat medium layer 2, and a copper foil layer 3;

[0032] In the graphene oxide superconducting heat-conducting aluminum-based copper-clad laminate, the aluminum substrate 1 , the non-conductive superconducting heat medium layer 2 , and the copper foil layer 3 are connected in a manner of sequentially placing heat-compression bonding.

[0033] In the flexible aluminum-based copper-clad laminate with high heat resistance, high thermal conductivity and high withstand voltage, the aluminum substrate 1 has a plate structure, the non-conductive superco...

specific Embodiment approach 2

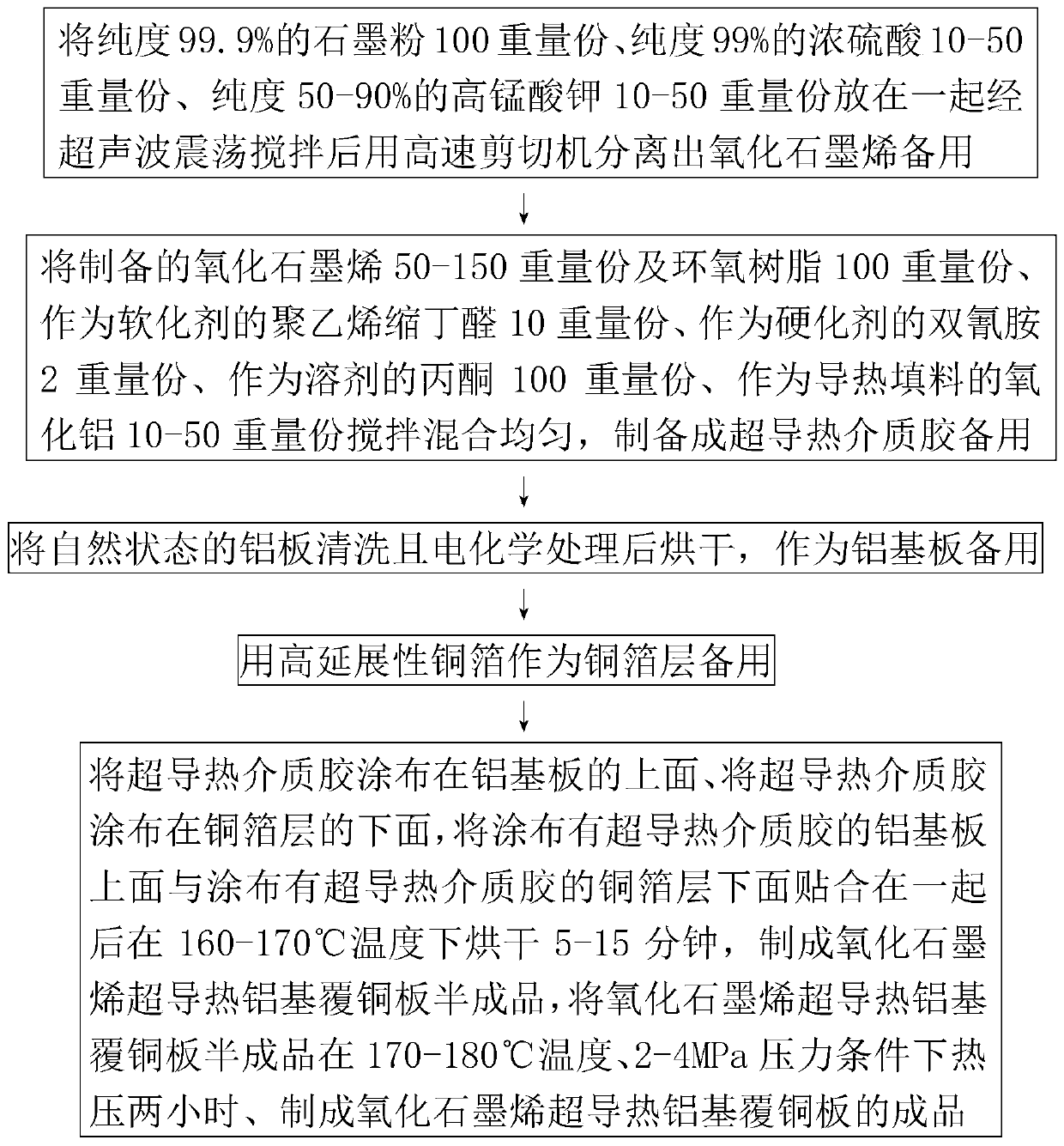

[0036] The "method for making graphene oxide superconducting heat-conducting aluminum-based copper-clad laminate" in the present invention will be described in detail below in conjunction with the accompanying drawings. As attached to the manual figure 2 Shown:

[0037] A kind of manufacture method of graphene oxide superconducting thermal aluminum-based copper-clad laminate:

[0038] 1. The preparation of graphene oxide: 100 parts by weight of graphite powder with a purity of 99.9%, 10-50 parts by weight of concentrated sulfuric acid with a purity of 99%, and 10-50 parts by weight of potassium permanganate with a purity of 50-90% are put together through After ultrasonic vibration and stirring, use a high-speed shear to separate graphene oxide for later use;

[0039] ②. Preparation of superconducting heat medium adhesive: 50-150 parts by weight of the graphene oxide prepared in ①, 100 parts by weight of epoxy resin, 10 parts by weight of polyvinyl butyral as a softener, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com