Nitrogen-doped porous carbon material, preparation method thereof, and application of material in supercapacitor

A nitrogen-doped porous carbon and nitrogen source technology, applied in the field of material science, can solve the problems of low capacity of activated carbon materials and difficulty in meeting actual needs, and achieve the effect of increasing the concentration of nitrogen doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

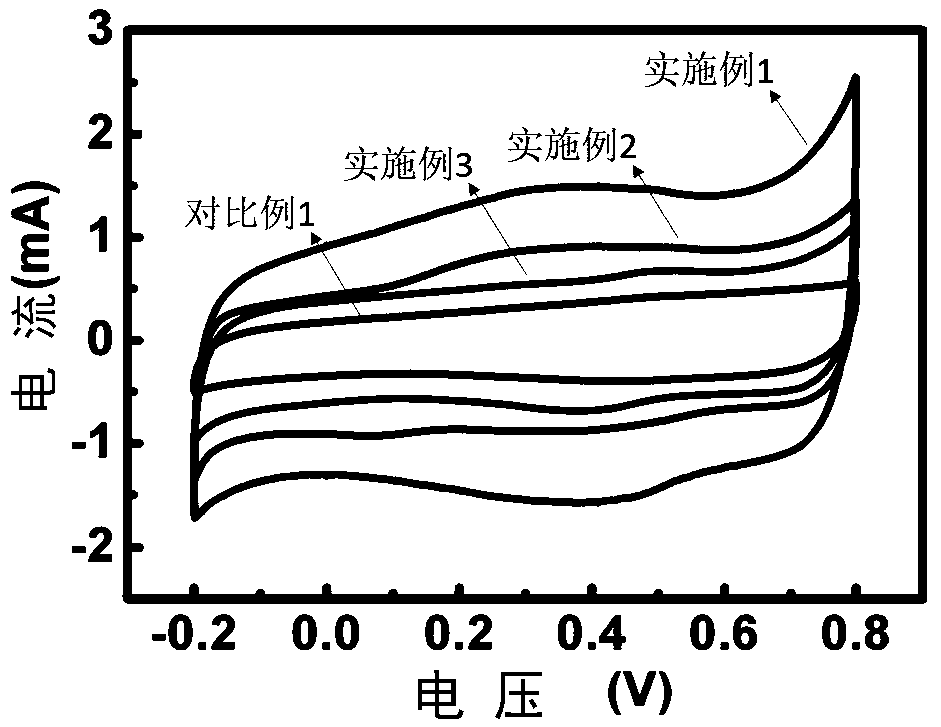

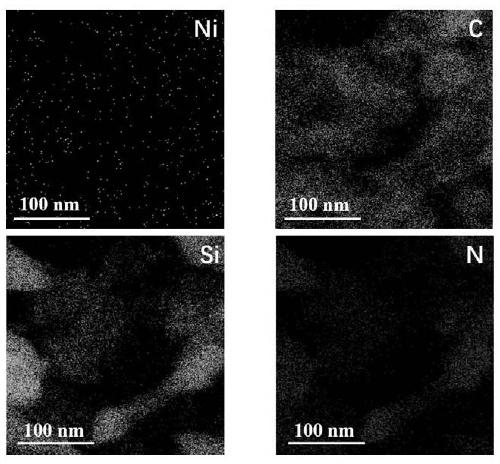

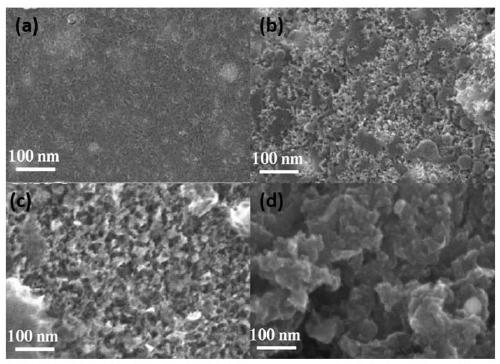

Embodiment 1

[0036] Measure 10mL absolute ethanol, add 1g Ni(NO 3 ) 2 6H 2 O, 2g P-123, 1g C 2 h 4 N 4 , 2g phenolic resin, 4ml tetraethyl orthosilicate and 0.4ml dilute hydrochloric acid (1mol / L). After the added raw materials are completely dissolved to form a clear solution, continue stirring for a period of time. Pour the prepared sol into a watch glass and let it stand for 2 days to slowly hydrolyze, and then put it in an oven at 50°C to make it gel for 2 days. Then grind to a homogeneous powder. The samples were heat-treated in a tube furnace at a temperature of 1000 °C. Heating from room temperature to 1000°C, the heating rate is 5°C / min, protective gas (argon, 300sccm, hydrogen, 50sccm) is required during the heating process, when the temperature in the furnace rises to 600°C, ammonia (NH 3 , 100 sccm), when the temperature reaches 1000 ° C, methane gas (flow rate of 5 sccm) is introduced, and the temperature is kept at 1000 ° C for 120 min. After the sample was cooled to...

Embodiment 2

[0039] Measure 10mL absolute ethanol, add 1g Ni(NO 3 ) 2 6H 2 O, 2g P-123, 1g C 2 h 4 N 4 , 2g phenolic resin, 2ml tetraethyl orthosilicate and 0.4ml dilute hydrochloric acid (1mol / L). After the added raw materials are completely dissolved to form a clear solution, continue stirring for a period of time. Pour the prepared sol into a watch glass and let it stand for 2 days to slowly hydrolyze, and then put it in an oven at 50°C to make it gel for 2 days. Then grind to a homogeneous powder. The samples were heat-treated in a tube furnace at a temperature of 1000 °C. Heating from room temperature to 1000°C, the heating rate is 5°C / min, protective gas (argon, 300sccm, hydrogen, 50sccm) is required during the heating process, when the temperature in the furnace rises to 600°C, ammonia (NH 3 , 100 sccm), when the temperature reaches 1000 ° C, methane gas (flow rate of 5 sccm) is introduced, and the temperature is kept at 1000 ° C for 120 min. After the sample was cooled to...

Embodiment 3

[0042] Measure 10mL absolute ethanol, add 1g Ni(NO 3 ) 2 6H 2 O, 2g P-123, 1g C 2 h 4 N 4 , 2g phenolic resin, 1ml tetraethyl orthosilicate and 0.4ml dilute hydrochloric acid (1mol / L). After the added raw materials are completely dissolved to form a clear solution, continue stirring for a period of time. Pour the prepared sol into a watch glass and let it stand for 2 days to slowly hydrolyze, and then put it in an oven at 50°C to make it gel for 2 days. Then grind to a homogeneous powder. The samples were heat-treated in a tube furnace at a temperature of 1000 °C. Heating from room temperature to 1000°C, the heating rate is 5°C / min, protective gas (argon, 300sccm, hydrogen, 50sccm) is required during the heating process, when the temperature in the furnace rises to 600°C, ammonia (NH 3 , 100 sccm), when the temperature reaches 1000 ° C, methane gas (flow rate of 5 sccm) is introduced, and the temperature is kept at 1000 ° C for 120 min. After the sample was cooled to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com