Novel water-based ink binder self-crosslinking emulsion for flexographic printing and preparation method thereof

A technology of ink binder and self-crosslinking emulsion, applied in ink, application, household appliances, etc., can solve the problems of inability to meet high-speed flexo printing technology, poor ink printing transferability, etc., and achieve excellent resolubility and printing transferability. , The effect of improving water resistance and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

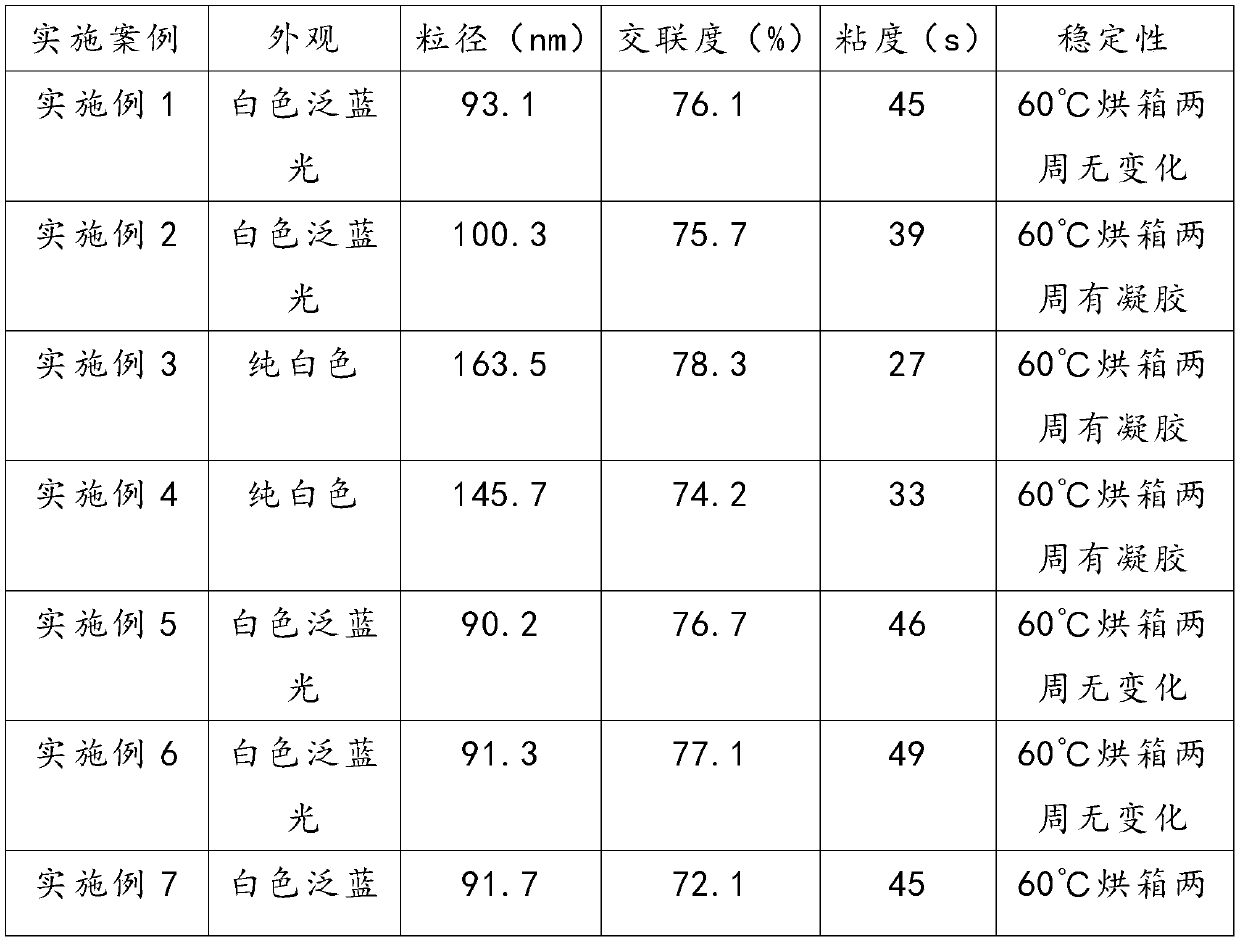

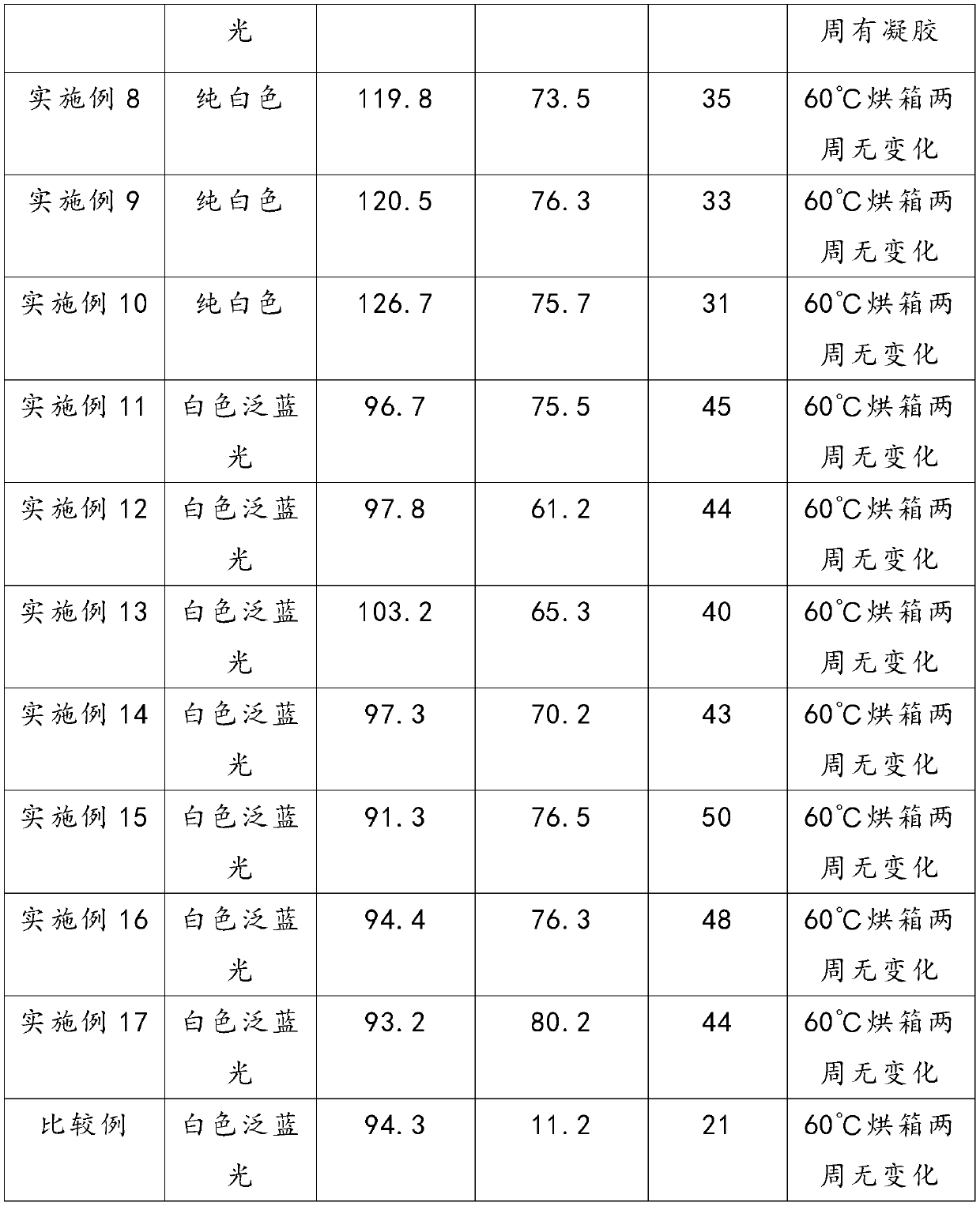

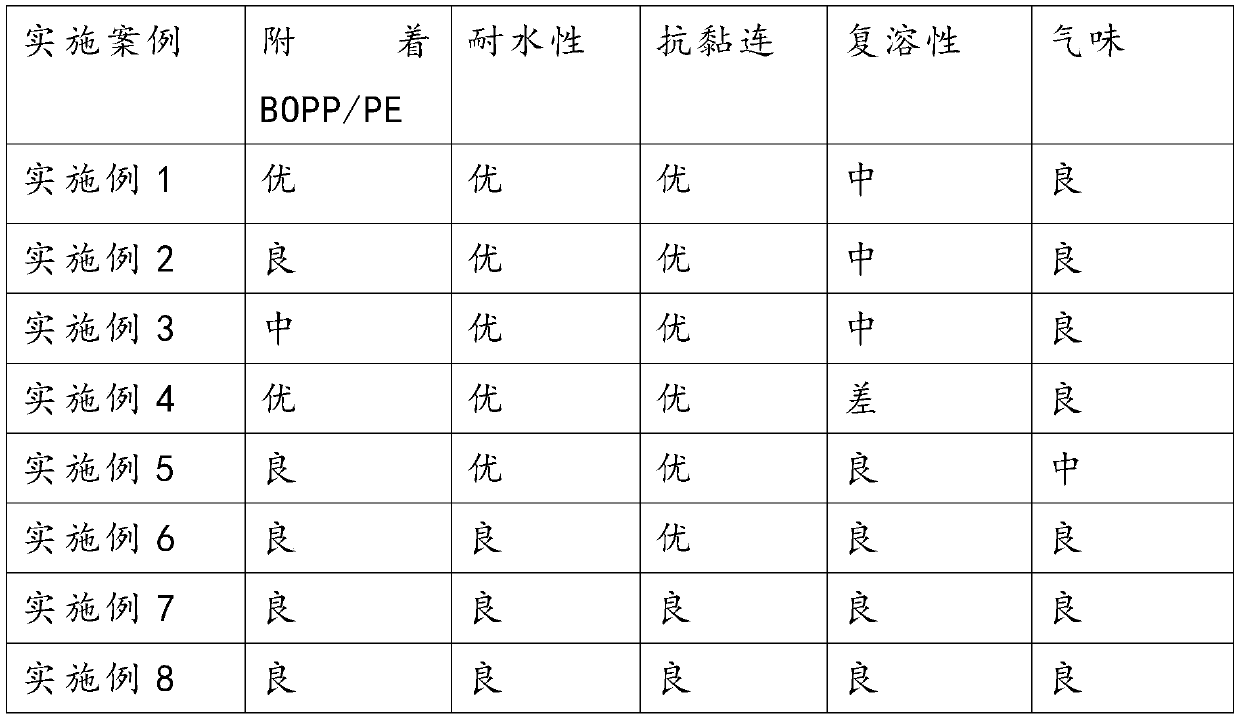

Examples

Embodiment 1

[0027] Dissolution of water-based resin: at a temperature of 80°C and a rotational speed of 300r / min, under a nitrogen atmosphere, add 140g of a water-based resin with a molecular weight of 7000, 656.3g of deionized water and 43.7g of ammonia water with a mass concentration of 25% in a 2L reactor. After stirring for 30-40 minutes, a pure and transparent water-based resin solution is obtained.

[0028] Preparation of monomer mixture: take 112.4g of styrene, 112.4g of methyl methacrylate, 87.6g of butyl acrylate, 87.6g of isooctyl acrylate, 8g of isobornyl acrylate, 8g of hydroxyethyl acrylate, and 12g of diacetone acrylamide and glycidyl methacrylate 2g, mixed evenly to obtain a yellow transparent solution.

[0029] The temperature is 86-88°C, the rotation speed is 300r / min, and under a nitrogen atmosphere, take 4wt% of the yellow transparent solution prepared above, add it to the dissolved water-based resin, and add 2g of sodium persulfate at the same time to obtain a blue see...

Embodiment 2

[0033] Dissolution of water-based resin: at a temperature of 80°C, a rotational speed of 300r / min, and a nitrogen atmosphere, 140g of a water-based resin with a molecular weight of 7000, 356.3g of deionized water, and 43.7g of ammonia water with a mass concentration of 25% were sequentially added to a 2L reactor. After stirring for 30-40 minutes, a pure and transparent water-based resin solution is obtained.

[0034] Preparation of monomer mixture: take 112.4g of styrene, 112.4g of methyl methacrylate, 87.6g of butyl acrylate, 87.6g of isooctyl acrylate, 8g of isobornyl acrylate, 8g of hydroxyethyl acrylate and 12g of diacetone acrylamide and glycidyl methacrylate 2g, mixed evenly to obtain a yellow transparent solution.

[0035] Preparation of pre-emulsion: Add 303.7 g of deionized water and 100 g of aqueous resin solution to the monomer mixture, and stir magnetically for 30 minutes to obtain a white pre-emulsion.

[0036] Add the remaining 440g of water-based resin solution...

Embodiment 3

[0039] Dissolution of water-based resin: at a temperature of 80°C, a rotational speed of 300r / min, and a nitrogen atmosphere, 140g of a water-based resin with a molecular weight of 7000, 356.3g of deionized water, and 43.7g of ammonia water with a mass concentration of 25% were sequentially added to a 2L reactor. After stirring for 30-40 minutes, a pure and transparent water-based resin solution is obtained.

[0040] Preparation of monomer mixture: take 112.4g of styrene, 112.4g of methyl methacrylate, 87.6g of butyl acrylate, 87.6g of isooctyl acrylate, 8g of isobornyl acrylate, 8g of hydroxyethyl acrylate and 12g of diacetone acrylamide and glycidyl methacrylate 2g, mixed evenly to obtain a yellow transparent solution

[0041] Preparation of fine emulsion: Add 303.7 g of deionized water, 100 g of aqueous resin solution, and 2 g of stearyl acrylate to the monomer mixture, and disperse for 10 minutes with a cell breaker to obtain a white fine emulsion.

[0042] Add the remain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com