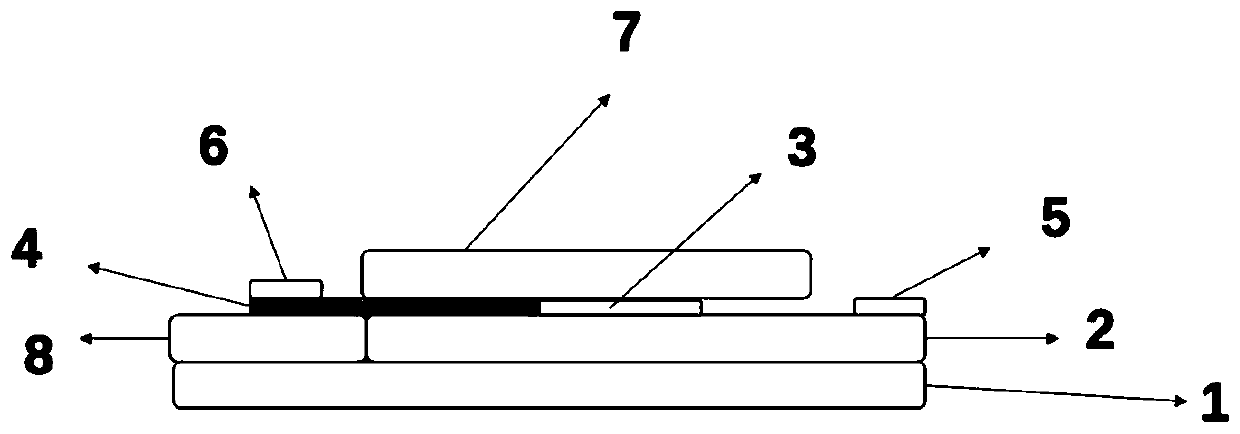

Single ZnO:Ga micron wire heterojunction base point light source device and preparation method thereof

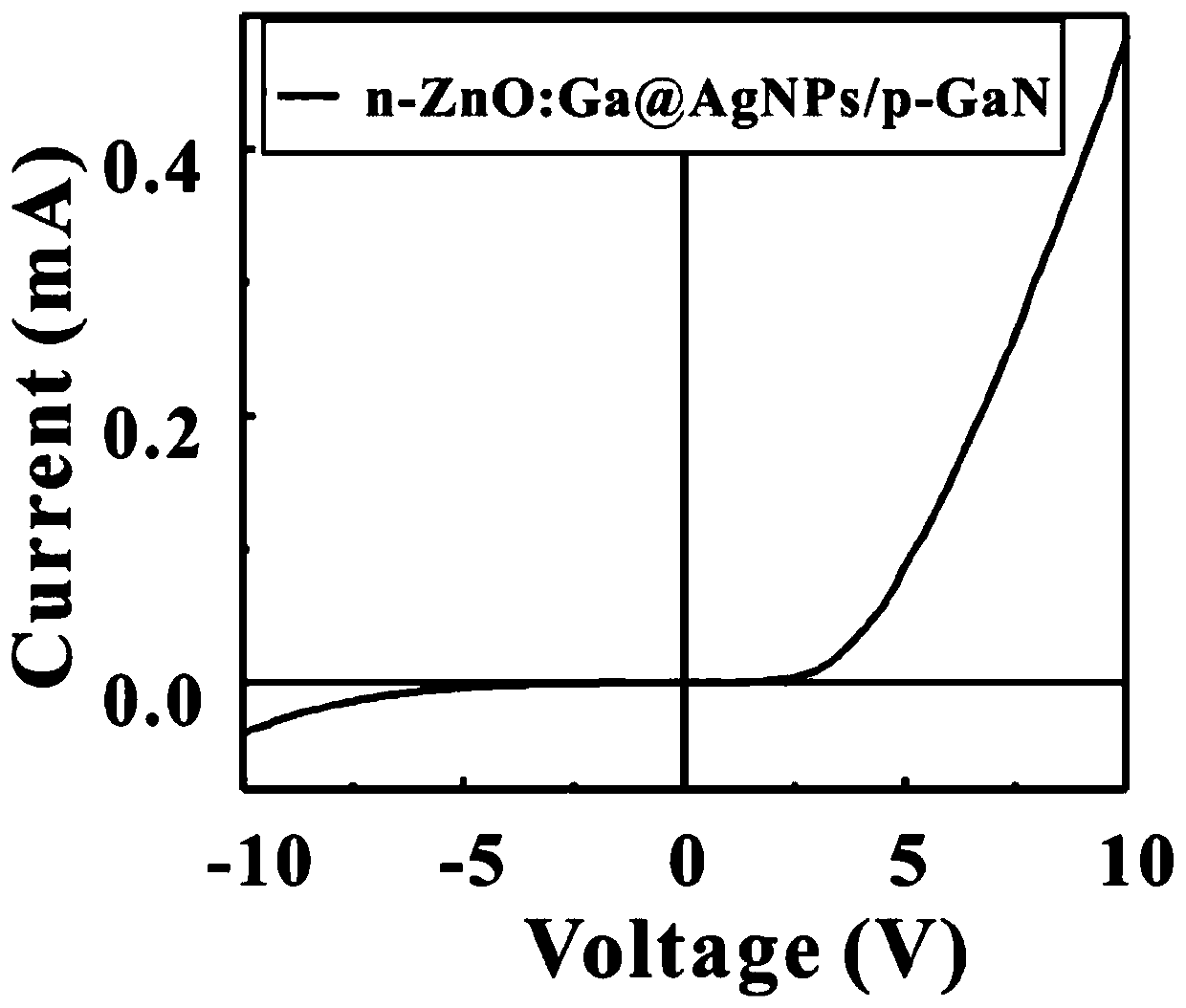

A micro-wire and heterojunction technology, applied in semiconductor devices, electrical components, nanotechnology, etc., can solve the problems of low luminous efficiency, difficult p-type doping, low effective carrier injection rate, etc., to suppress surface defects. , the effect of improving the local conductivity and increasing the effective injection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The first step: place the p-GaN substrate in a high-temperature tube furnace for annealing at 700-900°C for 1-2 hours, and then clean the p-GaN substrate with trichlorethylene, acetone, ethanol, and deionized water in sequence after annealing , dry with nitrogen, and finally use electron beam evaporation to evaporate two layers of electrodes on one end of p-GaN to form a 30nm thick Ni / Au electrode, and test the ohmic characteristics of the electrode.

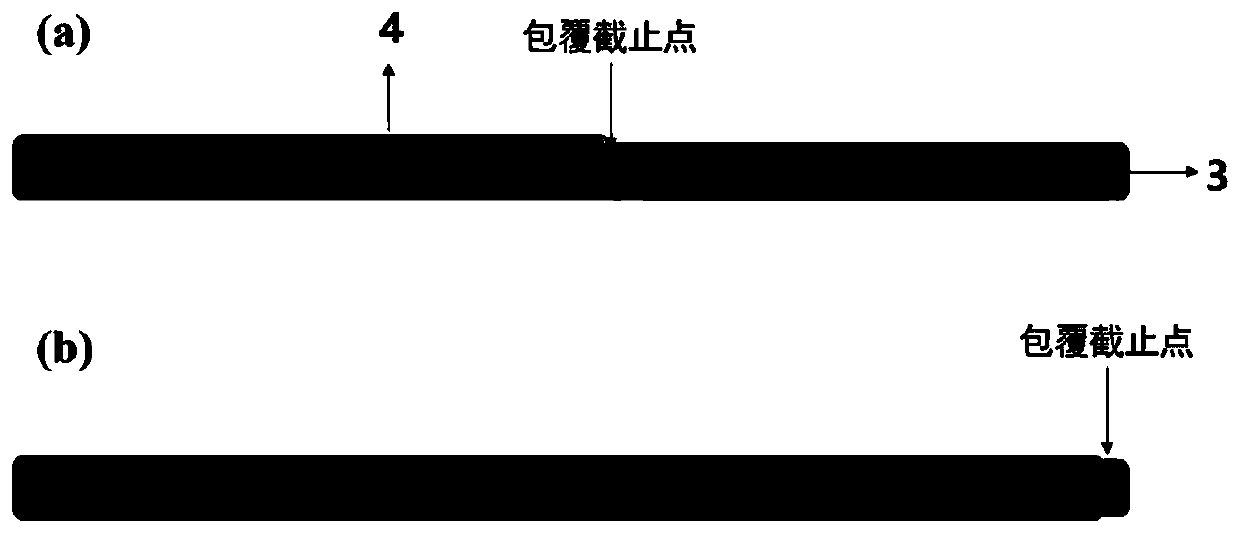

[0037] Step 2: Take a single quadrilateral ZnO:Ga micron wire with a length of 0.5cm to 1cm, and use a plasma sputtering device to sputter a layer of dense Ag nanoparticles with a thickness of 30nm on the surface of the ZnO:Ga micron wire. Among them, the mask plate used before sputtering is made of metal with different specifications, which is beneficial to shield sputtering in any area on the surface of the micron line; the sputtering target is an Ag target, the size is 50.8*1.0mm, the purity is 99.99%, and the working g...

Embodiment 2

[0041] The first step: place the p-GaN substrate in a high-temperature tube furnace for annealing at 700-900°C for 1-2 hours, and then clean the p-GaN substrate with trichlorethylene, acetone, ethanol, and deionized water in sequence after annealing , dry with nitrogen, and finally use electron beam evaporation to evaporate two layers of electrodes on one end of p-GaN to form a 30nm thick Ni / Au electrode, and test the ohmic characteristics of the electrode.

[0042] Step 2: Take a single quadrilateral ZnO:Ga micron wire with a length of 0.5cm to 1cm, and use a plasma sputtering device to sputter a layer of dense Ag nanoparticles with a thickness of 30nm on the surface of the ZnO:Ga micron wire. Among them, the mask plate used before sputtering is made of metal with different specifications, which is beneficial to shield sputtering in any area on the surface of the micron line; the sputtering target is an Ag target, the size is 50.8*1.0mm, the purity is 99.99%, and the working g...

Embodiment 3

[0046] The first step: place the p-GaN substrate in a high-temperature tube furnace for annealing at 700-900°C for 1-2 hours, and then clean the p-GaN substrate with trichlorethylene, acetone, ethanol, and deionized water in sequence after annealing , dry with nitrogen, and finally use electron beam evaporation to evaporate two layers of electrodes on one end of p-GaN to form a 30nm thick Ni / Au electrode, and test the ohmic characteristics of the electrode.

[0047] Step 2: Take a hexagonal ZnO:Ga single micron wire with a length of 0.8cm to 1.5cm, press the indium grain on one end, place the pressed indium grain end at the clamp of the self-made spin coater, and set the spin coating time to 20min , the pulling speed is 0.05mm / min, the concentration of the Ag nanowire solution used is about 0.03-0.2g / mL, the length of the Ag nanowire is 3-100um, and the width is 30-130nm, and then placed in a drying oven at 80°C for 10min.

[0048] Step 3: Transfer the micron wires obtained in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Electron mobility | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com