A kind of preparation method of high-power type lithium-ion battery conductive agent and lithium-ion battery

A lithium-ion battery and conductive agent technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as large ion diffusion resistance, weak fast charging performance, and hindering battery power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

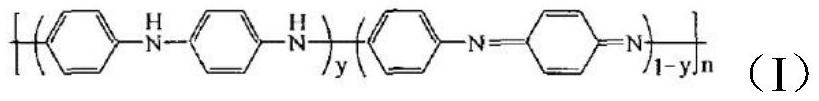

[0025] A preparation method of a high-power type lithium-ion battery conductive agent, comprising the following steps:

[0026] Step 1: Add the polymer monomer into the aqueous solution containing the templating agent, disperse evenly, stand at -30-50°C for 0.5-24h, add a polymer initiator to initiate the polymerization of the polymer monomer, and stand for 24h to obtain A conductive agent polymer suspension with a solid content of 5-55% by weight;

[0027] Step 2: After the conductive agent polymer suspension is centrifuged, the lower precipitate is ultrasonically washed with absolute ethanol, and then centrifuged again, and the washing and centrifuged steps are repeated several times until the upper layer after centrifugation is colorless and clear. After removing the supernatant, place the lower precipitate in a vacuum drying oven at 60-90°C for 12-48 hours in a vacuum environment and grind to obtain solid powder S;

[0028] Step 3: Place the solid powder S in N 2 Or high...

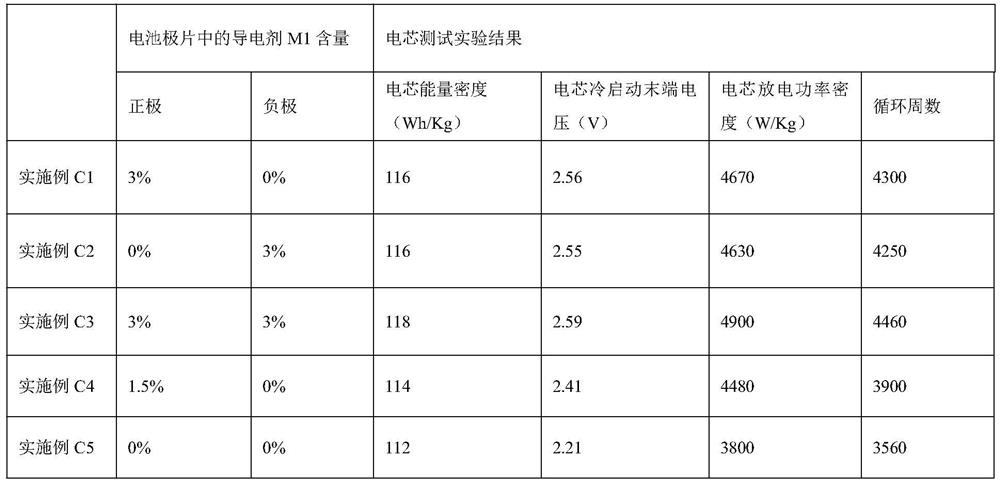

Embodiment 1

[0040] (1) Preparation of new high-power lithium-ion battery conductive agent M1

[0041] Add the aniline monomer into the aqueous solution of 0.4wt.% cetyltrimethylammonium chloride, disperse evenly and keep it at 25°C for 4 hours, then add ammonium persulfate equivalent to the aniline monomer into the solution to initiate Polymerize and stand for 24 hours to obtain a conductive agent polymer suspension with a solid content of 5-55wt%. After the conductive agent polymer suspension is centrifuged, the lower sediment is ultrasonically washed with absolute ethanol, and the ultrasonic frequency is 80- 150KHz, ultrasonic time is 30min, then centrifugal separation, repeat the washing and centrifugal separation steps several times, until the supernatant liquid after centrifugation is colorless and clear, after removing the supernatant liquid, put the lower precipitate in a vacuum drying oven at 85°C The environment was dried for 12h and ground to obtain a solid powder S; the solid p...

Embodiment 2

[0049] The difference between Example 2 and Example 1 lies in that the conductive agent D1 in the positive electrode sheet P1 contains 100 wt% of M1 instead of 100 wt% of conductive carbon black Super-P. In the negative electrode sheet N1, the conductive agent E1 contained 100wt% of conductive carbon black Super-P was changed to 100wt% of M1. The prepared battery is denoted as C2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com