Alkaline anion exchange membrane, preparation method thereof and preparation method of formate fuel cell

An anion exchange membrane and alkaline anion technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of poor chemical stability, dimensional stability, low ion conductivity, poor mechanical properties, etc., and achieve good chemical stability, Effect of high ionic conductivity and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

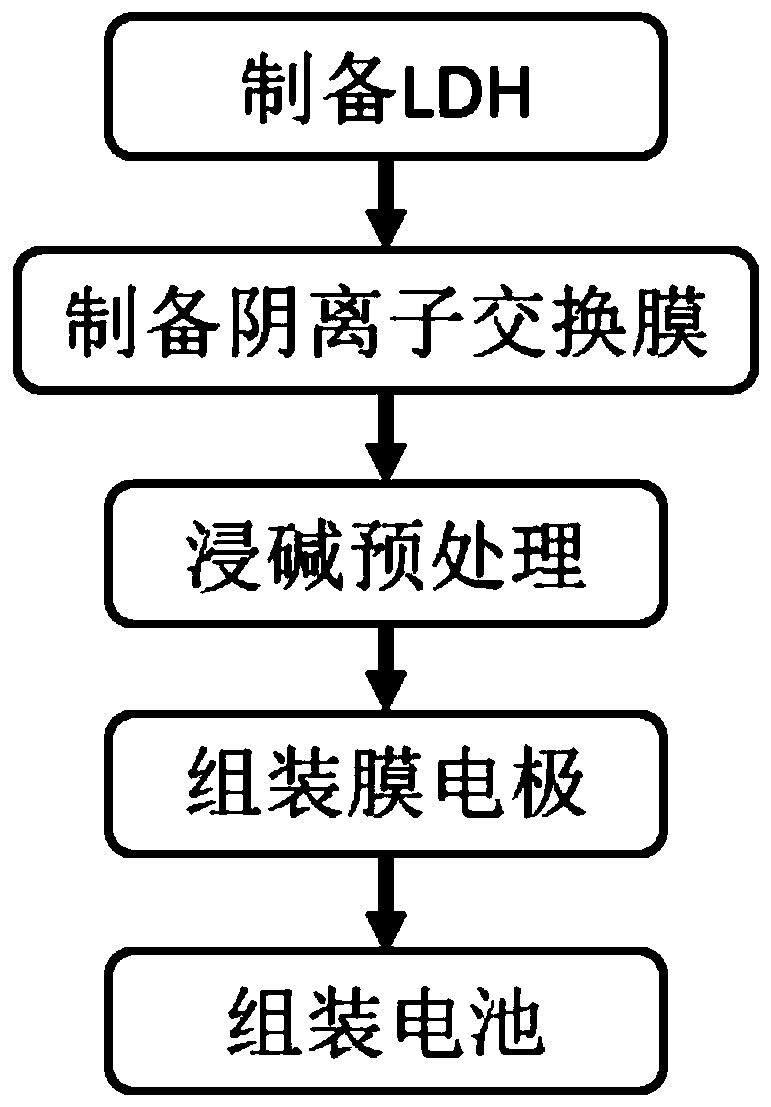

[0047] The process of preparing the basic anion exchange membrane of this example is:

[0048] 1) Preparation of magnesium-aluminum layered double hydroxide

[0049] Measure 4.6 mL of formamide and 15.4 mL of deionized water to prepare a formamide solution with a volume fraction of 23 vol%, add 17 mg of sodium nitrate to dissolve, and stir magnetically at 80°C until uniform.

[0050] Prepare 20mL of a mixed aqueous solution of 0.040M magnesium nitrate and 0.010M aluminum nitrate.

[0051] Add the mixed solution of magnesium nitrate and aluminum nitrate dropwise to the solution of formamide and sodium nitrate. The solution is magnetically stirred at 80°C. At the same time, 0.25M sodium hydroxide solution is added dropwise to adjust the pH of the system to 9-10.

[0052] The reaction time of the solution was 10 minutes.

[0053] The reacted product was centrifuged and washed three times with deionized water to obtain a transparent magnesium-aluminum double hydroxide colloid. ...

Embodiment 2

[0068] The process of preparing the basic anion exchange membrane of this example is:

[0069] 1) Preparation of magnesium-aluminum layered double hydroxide

[0070] Measure 4.6 mL of formamide and 15.4 mL of deionized water to prepare a formamide solution with a volume fraction of 23 vol%, add 15 mg of sodium nitrate to dissolve, and stir magnetically at 80 degrees Celsius to make it even.

[0071] Prepare 20 mL of a mixed aqueous solution of 0.040M magnesium nitrate and 0.010M aluminum nitrate.

[0072] Add the mixed solution of magnesium nitrate and aluminum nitrate dropwise to the solution of formamide and sodium nitrate. The solution is magnetically stirred at 85°C. At the same time, 0.25M sodium hydroxide solution is added dropwise to keep the pH of the system at 9-10.

[0073] The reaction time was 10 minutes.

[0074] The reacted product is centrifuged and washed 2-3 times with deionized water to obtain a transparent magnesium-aluminum double hydroxide colloid.

[0...

Embodiment 3

[0089] The process of preparing the basic anion exchange membrane of this example is:

[0090] 1) Preparation of magnesium-aluminum layered double hydroxide

[0091] Measure 4.6mL of formamide and 15.4mL of deionized water to prepare a formamide solution with a volume fraction of 23vol%, add 20mg of sodium nitrate to dissolve, and stir magnetically at 80°C until uniform.

[0092] Prepare 20mL of a mixed aqueous solution of 0.040M magnesium nitrate and 0.010M aluminum nitrate.

[0093] The mixed solution of magnesium nitrate and aluminum nitrate was added dropwise to the formamide and sodium nitrate solution, and the solution was magnetically stirred at 80°C. At the same time, 0.25M sodium hydroxide solution was added dropwise to keep the pH of the system at 10.

[0094] The reaction time was 10 minutes.

[0095] The reacted product is centrifuged and washed 2-3 times with deionized water to obtain a transparent magnesium-aluminum double hydroxide colloid.

[0096] The produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com