Method for extracting chondroitin sulfate and collagen peptide from animal cartilage

A chondroitin sulfate and collagen peptide technology, which is applied in the production process and the extraction of collagen peptides by enzymatic hydrolysis, can solve the problems of suboptimal production methods and high production costs, and achieve the effects of white color, improved benefits, and increased economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

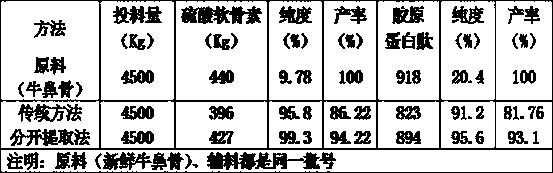

Embodiment 1

[0064] A preparation method utilizing animal cartilage to produce chondroitin sulfate and collagen peptides respectively, comprising the steps of:

[0065] (1) Cartilage treatment: Put 4500Kg of fresh bovine nasal bone into a 10000L reactor, add purified water to 9000L, and adjust the temperature of the feed liquid to 36.9°C.

[0066] (2) Use acetic acid to adjust the pH value of the feed solution to 4.5, extract at 36.9°C for 8 hours (use acetic acid to maintain the pH value of 4.5±0.2 during the extraction process), and after the extraction is completed, transfer the extract solution and filter it with a plate and frame Machine filter to get the extract, and the extract enters the next process. The remaining cartilage goes to another process.

[0067] Extraction treatment:

[0068] (2a) Concentrate the extract by ultrafiltration until the volume of the filtrate is 1 / 4 of the volume of the extract, then transfer the filtrate to an alcohol precipitation tank, start stirring ...

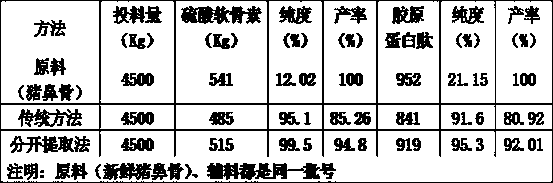

Embodiment 2

[0079] A preparation method for extracting chondroitin sulfate and collagen peptides from animal cartilage, comprising the steps of:

[0080] (1) Cartilage treatment: Put 4500Kg of fresh pig nose bones into a 10000L reactor, add purified water to 9000L.

[0081] (2) Adjust the temperature of the feed liquid to 36.8°C, adjust the pH value of the feed liquid to 4.4 with acetic acid, and extract for 8 hours (use acetic acid to maintain the pH value of 4.5±0.2 during the extraction process), after the extraction is completed, transfer the extract to a plate The extract is filtered by frame filter and enters the next process. The remaining cartilage goes to another process.

[0082] Extraction treatment:

[0083] (2a) Concentrate the extract by ultrafiltration with an ultrafiltration machine until the volume of the filtrate is 1 / 4 of the volume of the extract, stop the concentration, transfer the filtrate to the alcohol precipitation tank, start stirring and add ethanol (concentr...

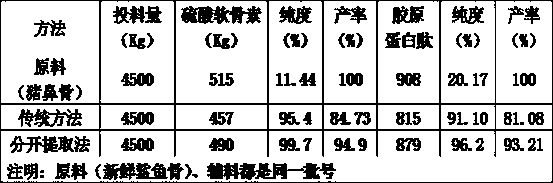

Embodiment 3

[0094] A preparation method for extracting chondroitin sulfate and collagen peptides from animal cartilage, comprising the steps of:

[0095] (1) Cartilage treatment: put 4500Kg of fresh shark bone into a 10000L reactor, add purified water to 9000L.

[0096] (2) Adjust the temperature of the feed liquid to 37.1°C, adjust the pH value of the feed liquid to 4.6 with acetic acid, and extract for 8 hours (keep the pH value of the feed liquid at 4.5±0.2 during the extraction process). Extract the liquid and filter it with a plate and frame filter to obtain the extract, and enter the next process. The remaining cartilage goes to another process.

[0097] Extraction treatment:

[0098] (2a) Concentrate the extract by ultrafiltration until the volume of the filtrate is 1 / 4 of the volume of the extract, transfer the filtrate to an alcohol precipitation tank, start stirring and add ethanol (concentration: 92.2%) to The concentration of ethanol in the alcohol precipitation system was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com