Ionic liquid gel electrolyte, preparation method thereof, and application thereof

A gel electrolyte and ionic liquid technology, which is applied in the manufacture of electrolyte batteries, composite electrolytes, non-aqueous electrolyte batteries, etc., can solve problems such as poor interface stability and poor mechanical properties of ionic liquid gel electrolytes, and achieve excellent mechanical properties , good thermal stability, and high room temperature ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The present invention also provides a preparation method of the above-mentioned ionic liquid gel electrolyte, comprising the following steps:

[0061] (1) Mix and stir the ionic liquid containing lithium salt, inorganic oxide precursor and formic acid in a mass ratio of 1:(0.010-0.030):(0.035-0.104) to obtain a first mixed system; in this step, the dioxide Inorganic network structure composed of silica is obtained by preparing silicon precursor by non-aqueous sol-gel method under catalytic action;

[0062] (2) mixing the molar ratio of 1:(0.005-0.020):(0.001-0.01) polymer monomer N,N-dimethylacrylamide, crosslinking agent and initiator to obtain a second mixed system;

[0063] (3) after the second mixed system is added to the first mixed system, a reaction precursor mixed solution is obtained; wherein, the mass ratio of the ionic liquid containing lithium salt and N,N-dimethylacrylamide is 1:( 0.05-0.2); transfer the reaction precursor mixed solution into a mold, or us...

Embodiment 1

[0079] Weigh 2 g of Li(G4)TFSI, add 150 μL of ethyl orthosilicate and 198 μL of formic acid, and continue stirring at room temperature for 1.5 h at a rotational speed of 700 rpm. Subsequently, 0.4 g of N,N-dimethylacrylamide, 2.5 mg of N,N'-methylenebis(acrylamide) and 0.6 mg of α-ketoglutaric acid were added thereto, and the mixture was continuously stirred for 10 min to make it uniform. Pour the above mixed solution into a polytetrafluoroethylene mold, and use an ultraviolet light source with a wavelength of 365 nm and a power of 6 W to initiate the polymerization reaction. 2 Organic-inorganic double network structure ionic liquid gel.

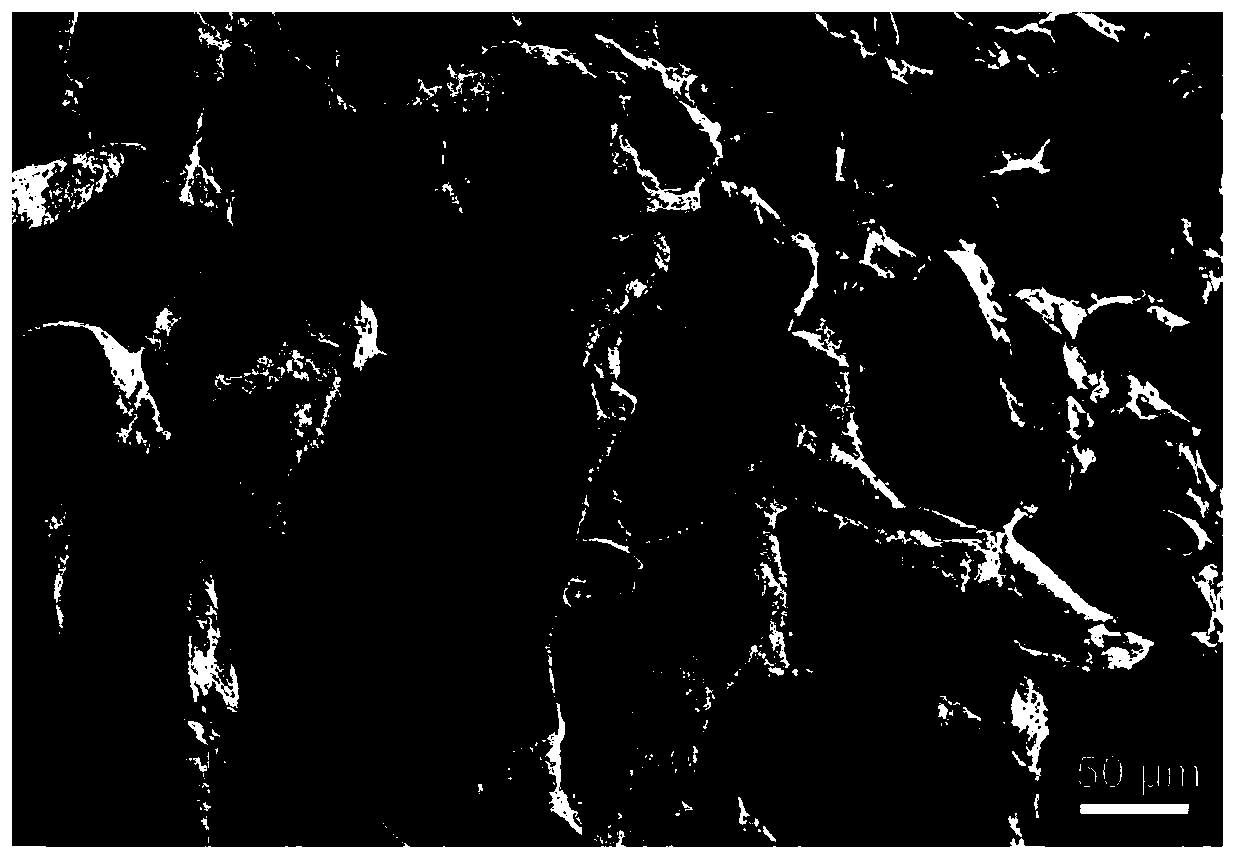

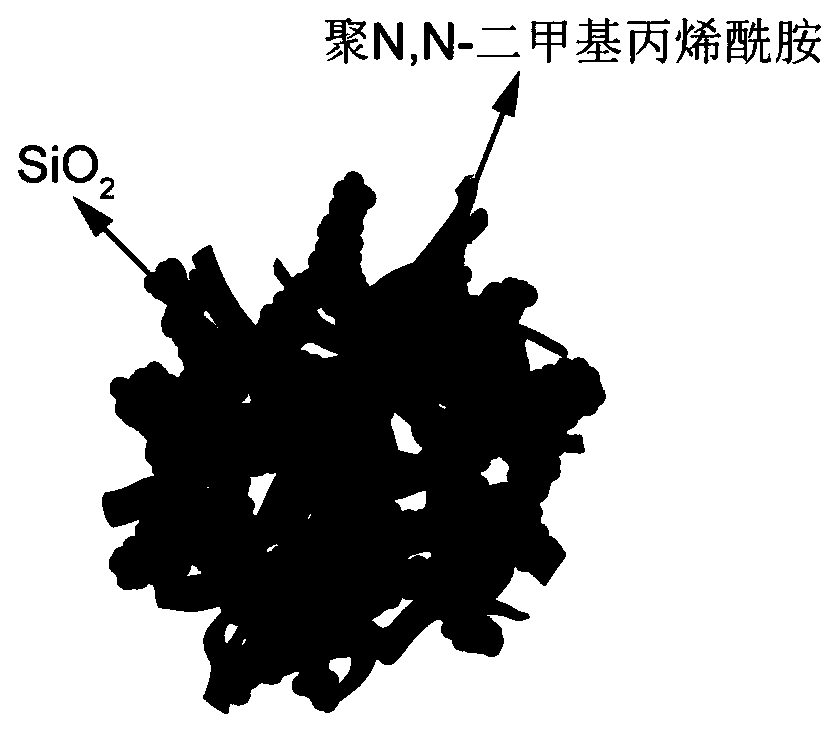

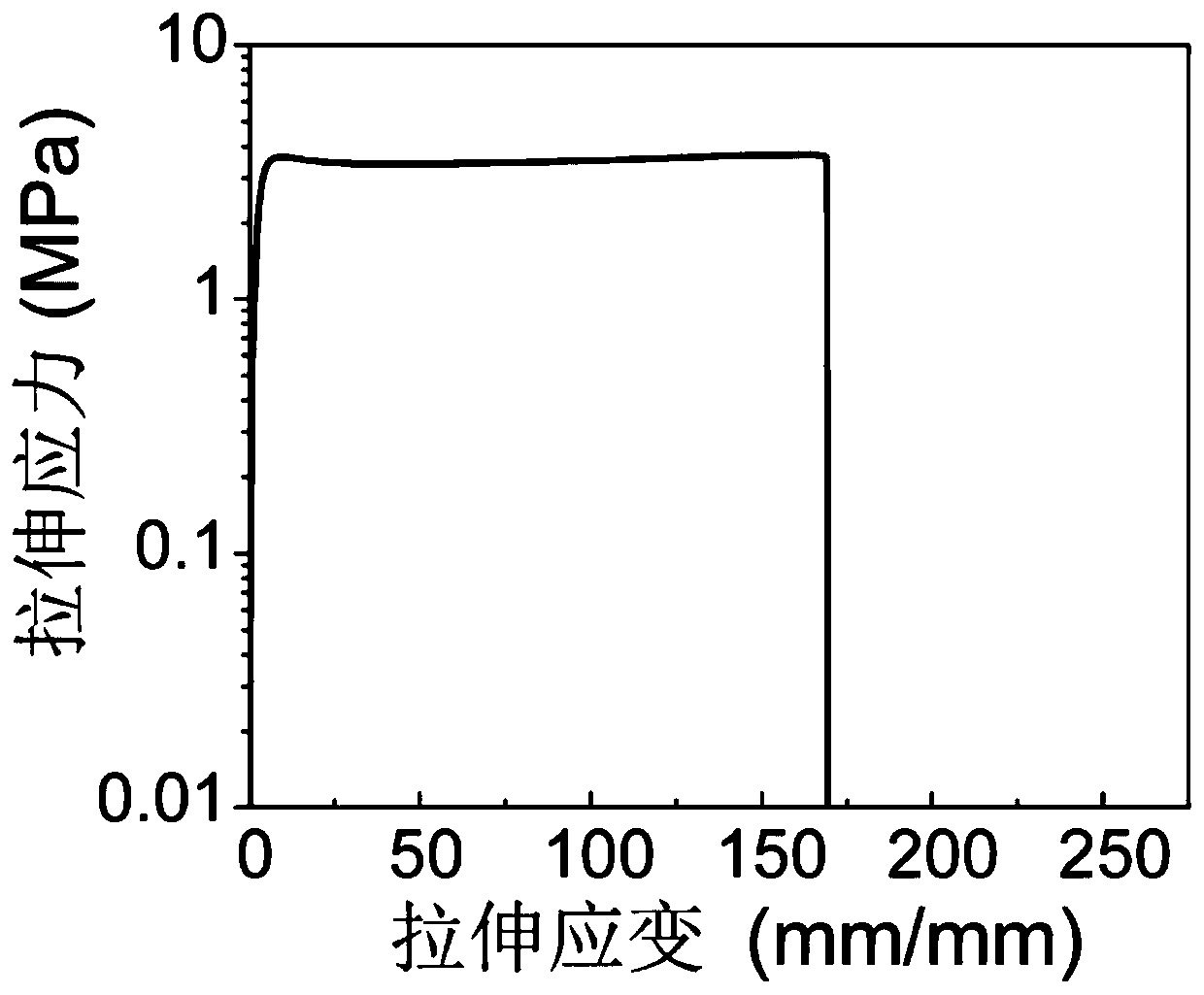

[0080] figure 1 It is shown that the electrolyte solid framework is distributed in a spatial three-dimensional network structure, and the two independent networks are each cross-linked and penetrate each other, figure 2 for this polyN,N-dimethylacrylamide / SiO 2 Schematic illustration of the organic-inorganic double network structure. i...

Embodiment 2

[0082] Weigh 2 g of Li(G4)TFSI, add 150 uL of ethyl orthosilicate and 198 uL of formic acid, and continue stirring at room temperature for 1.5 h at a rotational speed of 700 rpm. Subsequently, 0.4 g of N,N-dimethylacrylamide, 2.5 mg of N,N'-methylenebis(acrylamide) and 6.6 mg of azobisisobutyronitrile were added thereto, and stirring was continued for 10 min to make the mixture uniform. Coat a layer of the above mixed solution with a thickness of 100 μm on the polyethylene terephthalate substrate by a doctor blade coating method, and use a UV light source with a wavelength of 365 nm and a power of 300 W to initiate the polymerization reaction, and turn off the UV light source after 5 minutes. Obtained polyN,N-dimethylacrylamide / SiO with a thickness of 100 μm 2 Organic-inorganic double network structure ionic liquid gel membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com