Hydrothermal method for synthesizing biomass fluorescence carbon dots by taking soybean meals as raw materials and application

A raw material water and thermal synthesis technology, applied in the direction of fluorescence/phosphorescence, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problems of no corresponding, and achieve low cost, simple operation, and easy promotion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Uniformly mix the remaining fresh okara and ultrapure water at a ratio of 1:4 (weight ratio) to make a precursor solution for future use;

[0037] (2) Heat the obtained precursor solution (60mL) in a 100mL stainless steel autoclave at 200°C with magnetic stirring at 200rpm for 3h;

[0038] (3) Naturally cool to room temperature, filter or centrifuge to remove insoluble matter, the supernatant is dialyzed through a 1000Da dialysis bag, and freeze-dried at -50°C to obtain carbon quantum dot powder (50 mg), with a quantum yield of 3.7%.

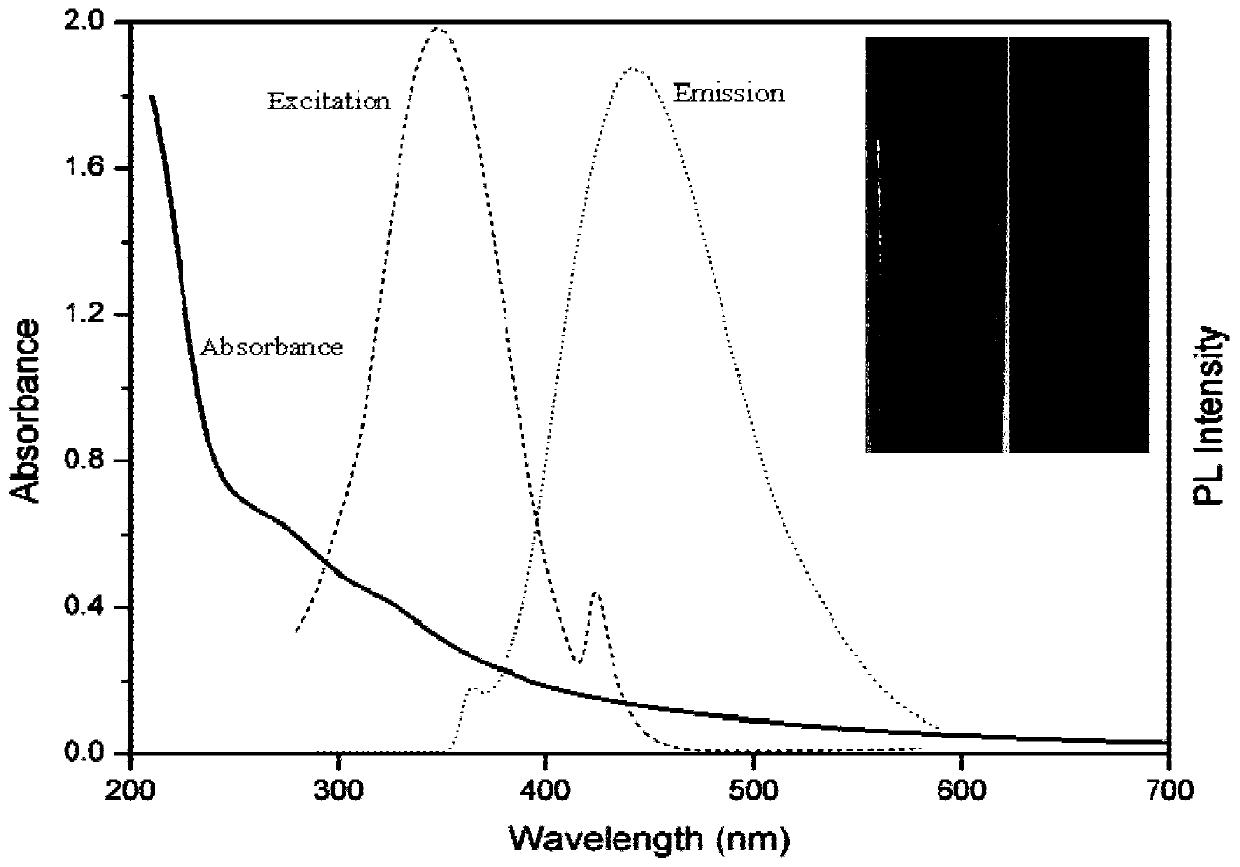

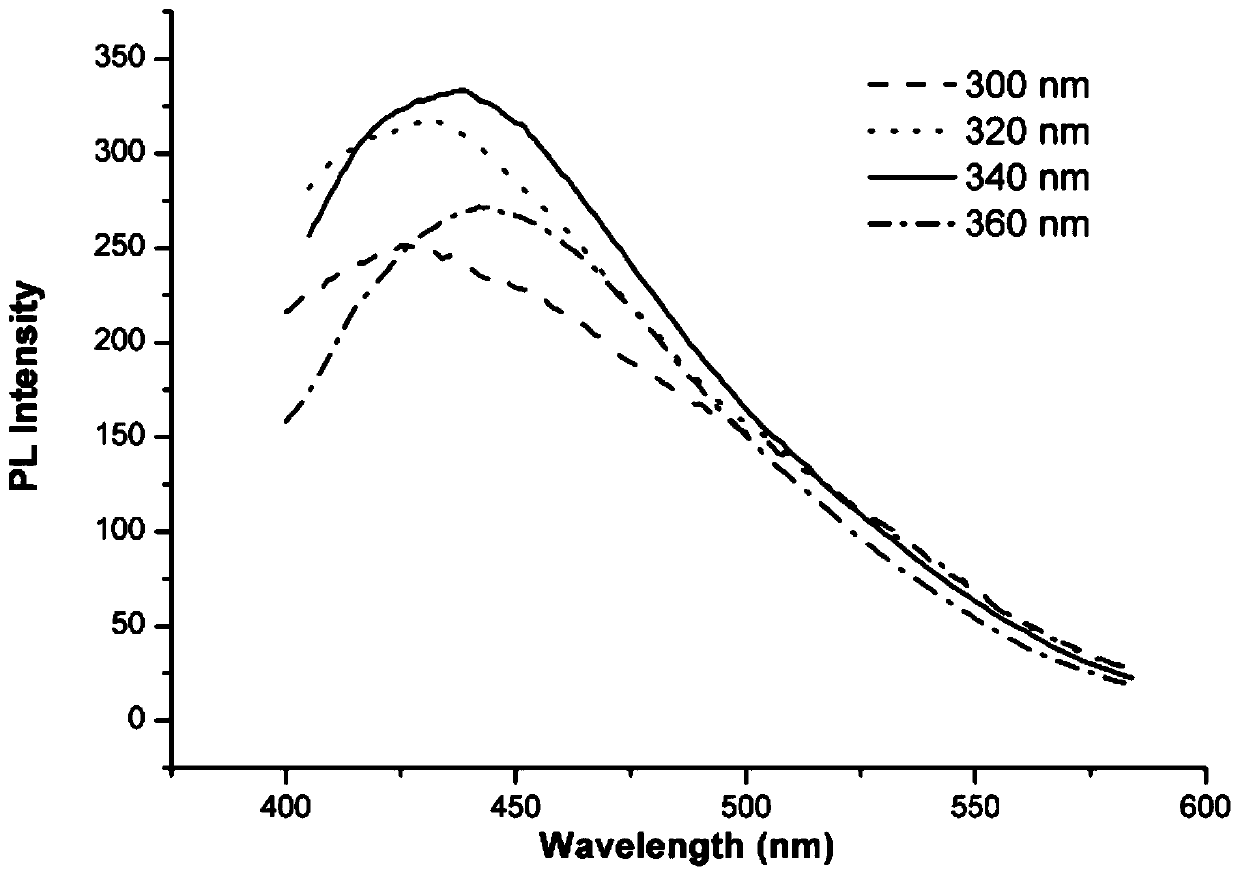

[0039]figure 1 It is the ultraviolet-visible absorption spectrum, (fluorescence) excitation spectrum and emission spectrum figure of the solution of the carbon quantum dot prepared under this experimental condition; From figure 1 It can be seen that the carbon quantum dot has significant absorption in the ultraviolet range of 210-400nm, the maximum excitation wavelength is 346nm, and the maximum emission wavelength is 440nm.

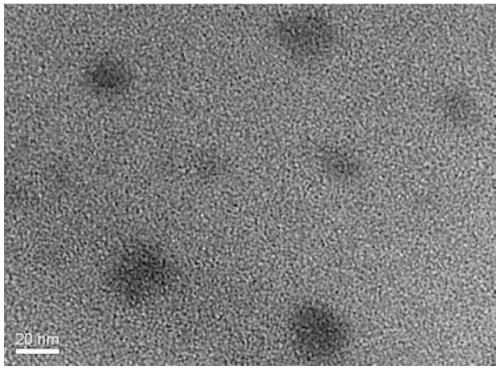

[0040]...

Embodiment 2

[0048] (1) Uniformly mix the remaining fresh okara and ultrapure water at a ratio of 1:2 to make a precursor solution for subsequent use;

[0049] (2) Heat the obtained precursor solution (60mL) in a 100mL stainless steel autoclave at 300°C with magnetic stirring at 200rpm for 3h;

[0050] (3) Naturally cool to room temperature, filter or centrifuge to remove insoluble matter, the supernatant is dialyzed through a 1000Da dialysis bag, and freeze-dried at -50°C to obtain carbon quantum dot powder (110mg), with a quantum yield of 4.7%.

Embodiment 3

[0052] (1) Uniformly mix the remaining fresh okara and ultrapure water at a ratio of 1:4 to make a precursor solution for future use;

[0053] (2) Heat the obtained precursor solution (60mL) in a 200mL polytetrafluoroethylene autoclave at 250°C for 5h;

[0054] (3) Naturally cool to room temperature, filter or centrifuge to remove insoluble matter, the supernatant is dialyzed through a 1000Da dialysis bag, and freeze-dried at -50°C to obtain 50 mg of carbon quantum dot powder with a quantum yield of 4.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum yield | aaaaa | aaaaa |

| quantum yield | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com