Acid etching silicon wafer waste acid liquid treatment method and system

A processing method and technology of silicon wafers, applied in the direction of calcium/strontium/barium halide, calcium/strontium/barium fluoride, etc., can solve the problems of resource waste and environmental pollution of fluorine ion and fluorosilicate ion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

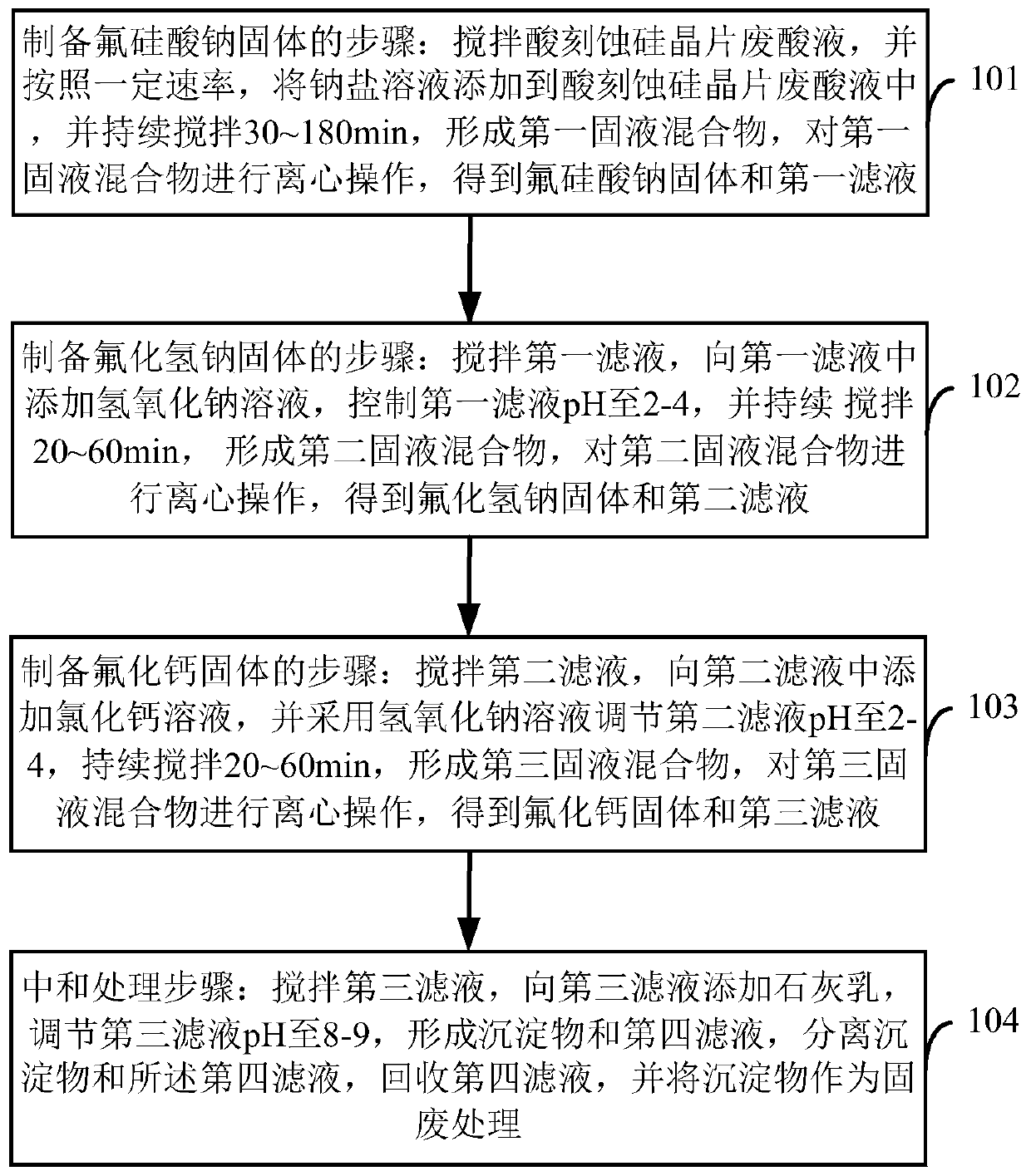

Method used

Image

Examples

Embodiment 1

[0096] Embodiment 1: For the annual production of 3GW crystalline silicon solar cell project, the amount of waste acid solution produced by acid etching silicon wafers is 50m 3 / d, the waste acid solution contains 5.88% fluosilicic acid, 11.1% hydrofluoric acid, 38% nitric acid and 1% hydrochloric acid. This implementation case includes the following steps:

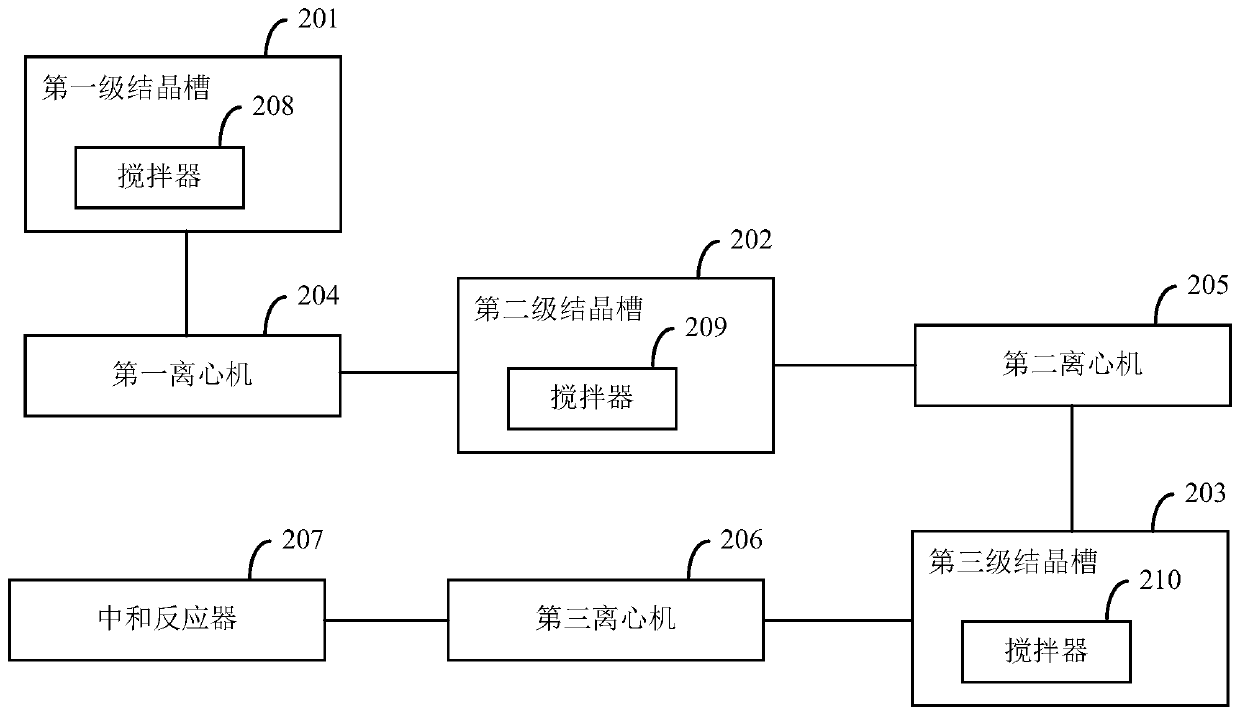

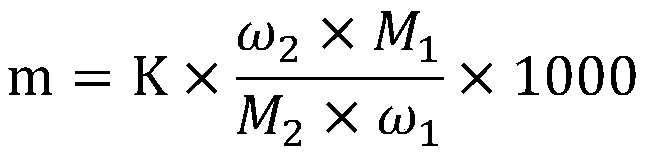

[0097] The steps for preparing sodium fluorosilicate solid: first put the waste acid solution of acid etching silicon wafer (hereinafter referred to as: waste acid solution) into the first-stage crystallization tank, start the stirrer, stir at 200rpm, and then mix 160kg / m 3 Pass the saturated sodium chloride solution into the crystallization tank at a constant speed, keep the reaction temperature at 25°C, and continue to stir for 30 minutes to react. After the reaction, pass the solid-liquid mixed solution into the centrifuge to separate the first filtrate and wet sodium fluorosilicate solid , and then wash and dry the w...

Embodiment 2

[0102] Example 2: Aiming at an annual production of 9GW crystalline silicon solar cell project, the amount of waste acid produced by acid etching silicon wafers is 120m 3 / d, the waste acid liquid contains 8.9% fluosilicic acid, 15.6% hydrofluoric acid, 42% nitric acid and 0.6% hydrochloric acid. This implementation case includes the following steps:

[0103] The steps for preparing sodium fluorosilicate solid: first put the waste acid solution into the first-stage crystallization tank, start the stirrer, stir at 180rpm, and then mix 154.6kg / m 3 Pass the saturated sodium nitrate solution into the crystallization tank at a uniform speed, keep the reaction temperature at 25°C, and continue to stir for 60 minutes to react. After the reaction is completed, pass the solid-liquid mixed solution into the centrifuge to separate the first filtrate and wet sodium fluorosilicate solid. Then the wet sodium fluorosilicate solid is washed and dried to obtain a sodium fluorosilicate dry pro...

Embodiment 3

[0108] Embodiment 3: For the annual production of 5GW crystalline silicon solar cell project, the amount of waste acid solution produced by acid etching silicon wafers is 50m 3 / d, the waste acid solution contains 10% fluosilicic acid, 13% hydrofluoric acid, 40% nitric acid and 0.7% hydrochloric acid. This implementation case includes the following steps:

[0109] The steps for preparing sodium fluorosilicate solid: first put the waste acid solution into the first-stage crystallization tank, start the stirrer, stir at 180rpm, and then add 290kg / m 3 Pass the saturated sodium chloride solution into the crystallization tank at a constant speed, keep the reaction temperature at 10°C, and continue to stir for 120 minutes to react. After the reaction, pass the solid-liquid mixed solution into the centrifuge to separate the first filtrate and wet sodium fluorosilicate solid , and then wash and dry the wet sodium fluorosilicate solid to obtain a sodium fluorosilicate dry product, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com