A microwave synthesis method of uranium-zirconium carbonitride powder

A technology of uranium-zirconium carbonitride and microwave synthesis, applied in nitrogen compounds, chemical instruments and methods, nitrogen and non-metallic compounds, etc., can solve the problems of easy sintering and agglomeration of green body, difficulty in forming solid solution at low reaction temperature, and increased difficulty, etc. problem, to achieve the effect of high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

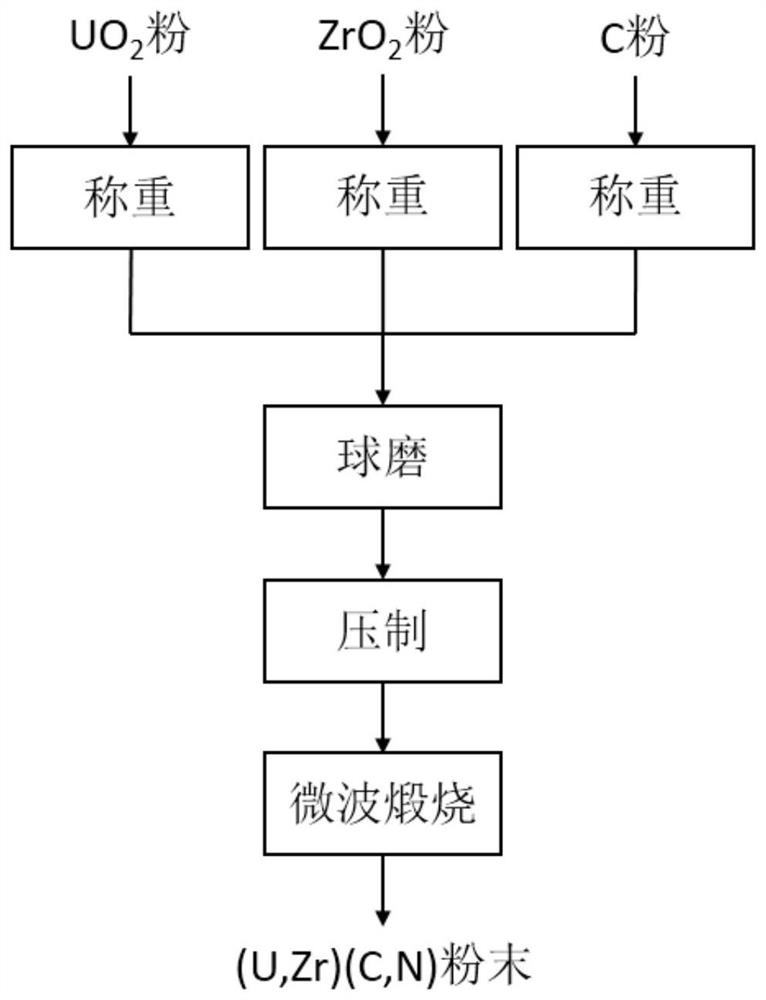

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Microwave synthesis of uranium-zirconium carbonitride powder (1)

[0028] Weigh UO 2 Powder 17.75g, ZrO 2 24.10g of powder and 8.15g of carbon powder were mixed and put into a high-energy ball mill for ball milling. The conditions were: the volume ratio of the ball to material was 3:1, the ball milling speed was 300 rpm, and the ball milling time was 16 hours.

[0029] Pour out the ball-milled material, separate the ball material and sieve to obtain a mixed powder, use a cemented carbide mold on a hydraulic press to press the mixed powder into a green body, the pressing pressure is 50MPa, and the holding time is 30s.

[0030] Put the pressed green body into a microwave high-temperature furnace and vacuumize to 10 -3 Pa, continuous feeding of high-purity N 2 , keeping N in the furnace 2 The pressure is 0.13MPa, microwave heating is turned on, the temperature is raised to 1600°C, and the temperature is kept for 1 hour to obtain (U,Zr)(C,N) powder, which ...

Embodiment 2

[0031] Embodiment 2: Microwave synthesis of uranium-zirconium carbonitride powder (two)

[0032] Weigh UO 2 Powder 29.57g, ZrO 2 13.38g of powder and 7.05g of carbon powder were mixed and put into a high-energy ball mill for ball milling. The conditions were: the volume ratio of the ball to material was 4:1, the ball milling speed was 400 rpm, and the ball milling time was 8 hours.

[0033] Pour out the ball-milled material, separate and sieve the ball material to obtain a mixed powder, use a cemented carbide mold on a hydraulic press to press the mixed powder into a green body, the pressing pressure is 80MPa, and the holding time is 20s.

[0034] Put the pressed green body into a microwave high-temperature furnace and vacuumize to 10 -3 Pa, continuous feeding of high-purity N 2 , keeping N in the furnace 2 The pressure is 0.12MPa, microwave heating is turned on, the temperature is raised to 1400°C, and the temperature is kept for 2 hours to obtain (U,Zr)(C,N) powder, whic...

Embodiment 3

[0035] Embodiment 3: Microwave synthesis of uranium-zirconium carbonitride powder (three)

[0036] Weigh UO 2 Powder 38.00g, ZrO 2 5.73g of powder and 6.27g of carbon powder were mixed and put into a high-energy ball mill for ball milling. The conditions were: the volume ratio of the ball to material was 5:1, the ball milling speed was 500 rpm, and the ball milling time was 4 hours.

[0037] Pour out the ball-milled material, separate the ball material and sieve to obtain a mixed powder, use a cemented carbide mold on a hydraulic press to press the mixed powder into a green body, the pressing pressure is 100MPa, and the holding time is 10s.

[0038] Put the pressed green body into a microwave high-temperature furnace and vacuumize to 10 -3 Pa, continuous feeding of high-purity N 2 , keeping N in the furnace 2 The pressure is 0.11MPa, microwave heating is turned on, the temperature is raised to 1300°C, and the temperature is kept for 4 hours to obtain (U,Zr)(C,N) powder, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com