Preparation method of patulin magnetic molecularly imprinted polymer

A technology of magnetic molecular imprinting and patulin, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of limited effective detection, cumbersome processing, poor selection ability, etc., and achieve high-efficiency separation and enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

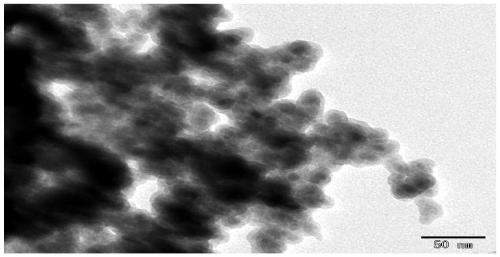

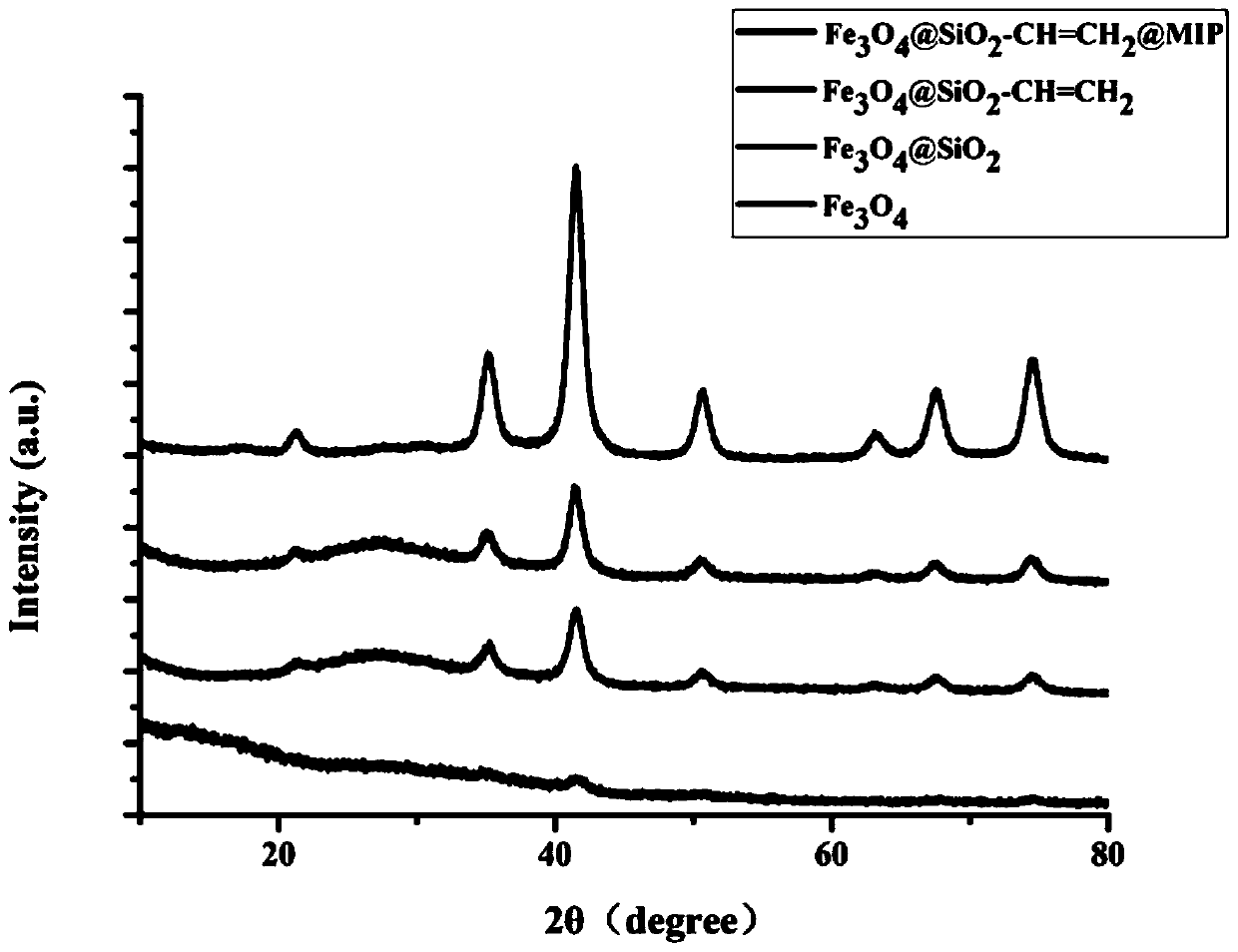

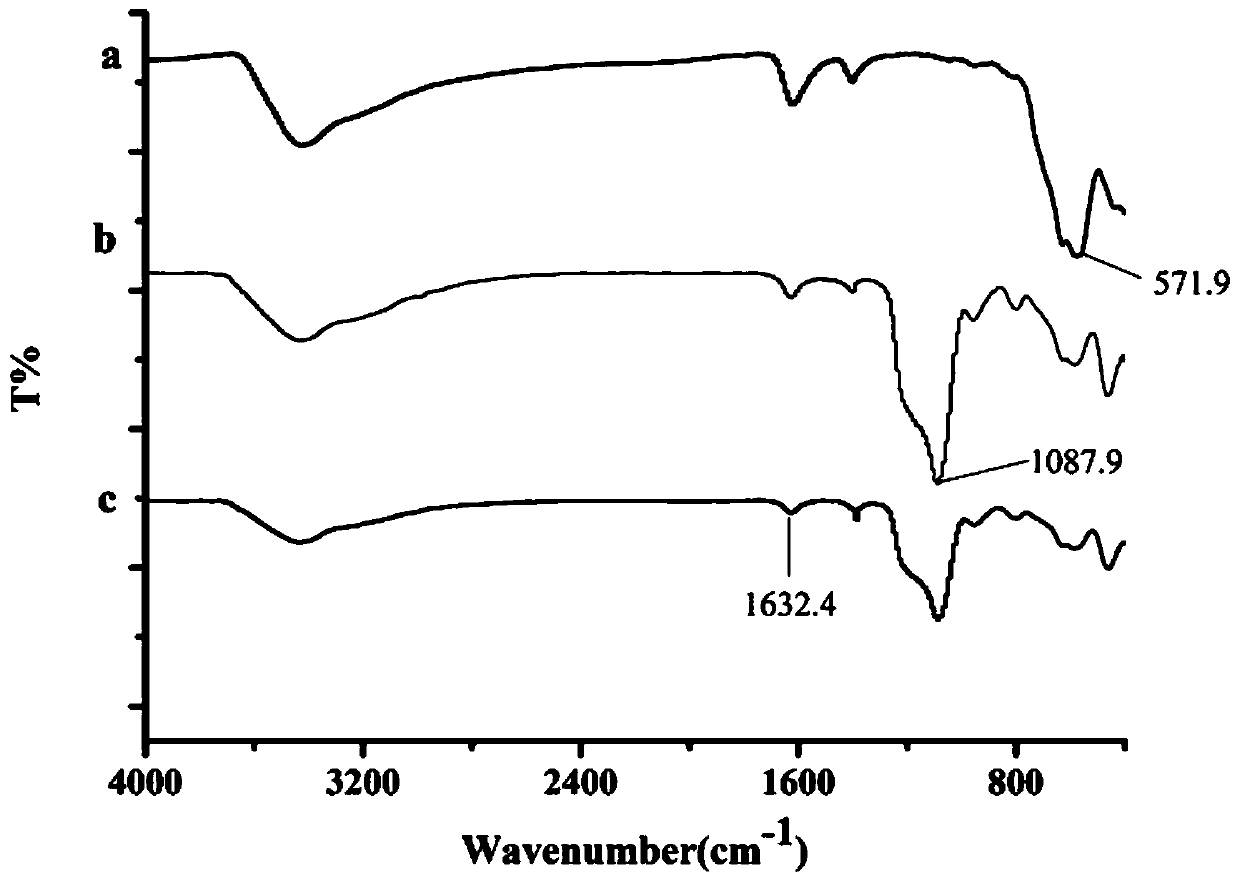

[0026] Preparation of Fe3O4 nanoparticles: Co-precipitation method was used to prepare Fe3O4 magnetic nanoparticles. Weigh 2.12g FeCl3·6H2O and 0.5g FeCl2·4H2O and ultrasonically disperse them in 5mL ultrapure water respectively. Transfer the above two solutions to a three-necked bottle, and add a certain amount of water to the bottle. Put it into an electric constant temperature water bath and stir the reaction. When the temperature rises to 70°C, add 6mL of 25% ammonia water, then raise the temperature to 80°C, stir for 10min, add 0.05g of sodium citrate, and stir for 10min. Cool to room temperature after the reaction is over, separate Fe3O4 with a magnet, wash with ethanol until it is neutral, and dissolve the obtained Fe3O4 solid in ethanol for preservation.

[0027] (2) Preparation of Fe3O4@SiO2 particles

[0028] Take the Fe3O4 magnetic nanoparticles prepared in the above steps into a 250mL three-necked flask, add 12mL of pure water and 48mL of ethanol, and disperse ul...

example 2

[0034](1) Preparation of Fe3O4 nanoparticles: Co-precipitation method was used to prepare Fe3O4 magnetic nanoparticles. Weigh 2.3g FeCl3·6H2O and 0.9g FeCl2·4H2O, respectively, and ultrasonically disperse them in 5mL ultrapure water. Transfer the above two solutions to a three-necked bottle, and add a certain amount of water to the bottle. Put it in an electric constant temperature water bath and stir for reaction. When the temperature rises to 70°C, add 10mL of 25% ammonia water, then raise the temperature to 80°C, stir for 40min, add 0.1g of sodium citrate, and stir for 20min. Cool to room temperature after the reaction is over, separate Fe3O4 with a magnet, wash with ethanol until it is neutral, and dissolve the obtained Fe3O4 solid in ethanol for preservation.

[0035] (2) Preparation of Fe3O4@SiO2 particles

[0036] Take the Fe3O4 magnetic nanoparticles prepared in the above steps into a 250mL three-necked flask, add 20mL pure water and 80mL ethanol, and disperse by ult...

example 3

[0042] (1) Preparation of Fe3O4 nanoparticles: Co-precipitation method was used to prepare Fe3O4 magnetic nanoparticles. Weigh 2.8g FeCl3·6H2O and 1.0g FeCl2·4H2O, respectively, and ultrasonically disperse them in 5mL ultrapure water. Transfer the above two solutions to a three-necked bottle, and add a certain amount of water to the bottle. Put it into an electric constant temperature water bath and stir for reaction. When the temperature rises to 70°C, add 15mL of 25% ammonia water, then raise the temperature to 80°C, stir for 40min, add 0.2g of sodium citrate, and stir for 20min. Cool to room temperature after the reaction is over, separate Fe3O4 with a magnet, wash with ethanol until it is neutral, and dissolve the obtained Fe3O4 solid in ethanol for preservation.

[0043] (2) Preparation of Fe3O4@SiO2 particles

[0044] Take the Fe3O4 magnetic nanoparticles prepared in the above steps into a 250mL three-neck flask, add 20mL pure water and 70mL ethanol, and ultrasonically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com