Preparation method of manganese cobalt oxide/porous carbon microsphere negative electrode material and product and application thereof

A negative electrode material, porous carbon technology, applied in negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of small diffusion coefficient, low conductivity, large volume change, etc. Chemical properties, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A manganese cobalt oxide / porous carbon microsphere negative electrode material is prepared according to the following steps:

[0026] (1) Dissolve 20 mmol of manganese chloride, 10 mmol of cobalt chloride and 20 mmol of sodium citrate in 100 mL of deionized water;

[0027] (2) Slowly add 100 mL of absolute ethanol to the above solution, and heat and magnetically stir in a water bath at 60 °C for 1.5 h to form a precipitate;

[0028] (3) The above precipitate was washed three times with deionized water and ethanol, and then freeze-dried at -80 °C for 24 h to obtain the manganese cobalt citrate precursor;

[0029] (4) The above precursor was calcined at 700 °C for 3 h under an inert argon atmosphere to obtain Mn 2 CoO 4 / Porous carbon microspheres.

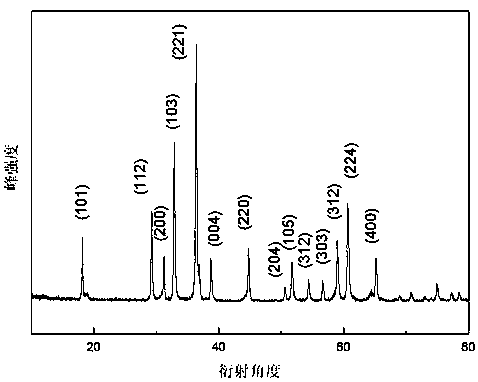

[0030] figure 1 is Mn 2 CoO 4 / XRD pattern of porous carbon microspheres. This material corresponds to JCPD#23-408. It has a square spinel structure. The spinel structure is conducive to the insertion and extraction of...

Embodiment 2

[0032] A manganese cobalt oxide / porous carbon microsphere negative electrode material is prepared according to the following steps:

[0033] (1) Dissolve 20 mmol manganese acetate, 10 mmol cobalt acetate and 20 mmol sodium citrate in 100 mL deionized water;

[0034] (2) Slowly add 100 mL of absolute ethanol to the above solution, and heat and magnetically stir in a water bath at 60 °C for 1.5 h to form a precipitate;

[0035] (3) The above precipitate was washed three times with deionized water and ethanol, and then freeze-dried at -80 °C for 24 h to obtain the manganese cobalt citrate precursor;

[0036] (4) The above precursor was calcined at 800 °C for 3 h under an inert argon atmosphere to obtain Mn 2 CoO 4 / Porous carbon microspheres.

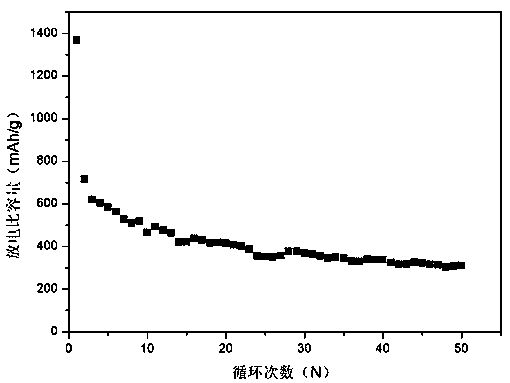

[0037] figure 2 is Mn 2 CoO 4 / Cycle diagram of porous carbon microspheres at a current density of 100 mA / g, the first discharge specific capacity is 1380 mAh / g, the second discharge specific capacity is 710 mAh / g, after 50 cycles,...

Embodiment 3

[0039] A manganese cobalt oxide / porous carbon microsphere negative electrode material is prepared according to the following steps:

[0040] (1) Dissolve 20 mmol manganese acetate, 10 mmol cobalt acetate and 20 mmol potassium citrate in 100 mL deionized water;

[0041] (2) Slowly add 100 mL of absolute ethanol to the above solution, and heat and magnetically stir in a water bath at 80 °C for 1 h to form a precipitate;

[0042] (3) The above precipitate was washed three times with deionized water and ethanol, and then freeze-dried at -80 °C for 48 h to obtain the precursor of manganese cobalt citrate;

[0043] (4) The above precursor was calcined at 600 °C for 5 h under an inert argon atmosphere to obtain Mn 2 CoO 4 / Porous carbon microspheres.

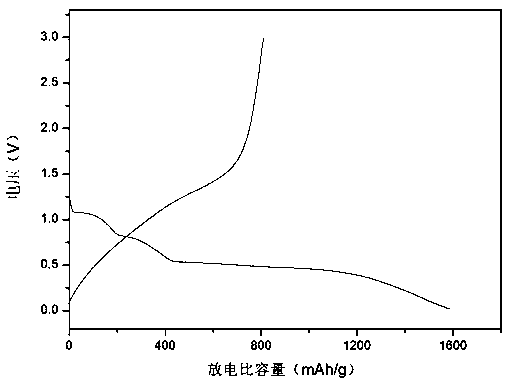

[0044] image 3 is Mn 2 CoO 4 / Porous carbon microspheres Mn under the condition of current density of 100 mA / g 2 CoO 4 / The first charge and discharge diagram of porous carbon microspheres, the first charge specific capacity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com