Growth factor sustained release microsphere, tissue engineering cartilage composite stent and preparation method

A growth factor and slow-release microsphere technology, applied in the field of medical materials, can solve the problems of difficulty in realizing self-repair and regeneration, aggravation, and low self-repair and regeneration ability of cartilage tissue, and achieve the effect of improving the effect of regeneration and repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The second aspect of the embodiments of the present invention provides a preparation method of growth factor sustained-release microspheres, through which the above-mentioned growth factor sustained-release microspheres can be prepared. The preparation method comprises the following steps:

[0057] S10, providing an aqueous rhTGF-β3 solution with a concentration of 1 μg / mL˜100 μg / mL.

[0058] In step S10, rhTGF-β3 may be dissolved in deionized water to prepare an aqueous solution of rhTGF-β3 with a concentration of 1 μg / mL-100 μg / mL as the internal water phase w 1 .

[0059] S20, providing a PLGA oil phase solution with a concentration of 20 mg / mL-25 mg / mL.

[0060] In step S20, PLGA may be dissolved in dichloromethane (DCM) to prepare a PLGA oil phase solution with a concentration of 20 mg / mL-25 mg / mL as the oil phase o. The oil phase o can have a higher encapsulation efficiency for rhTGF-β3.

[0061] In step S20, the molecular weight of PLGA is preferably 1×10 5 ...

Embodiment 1

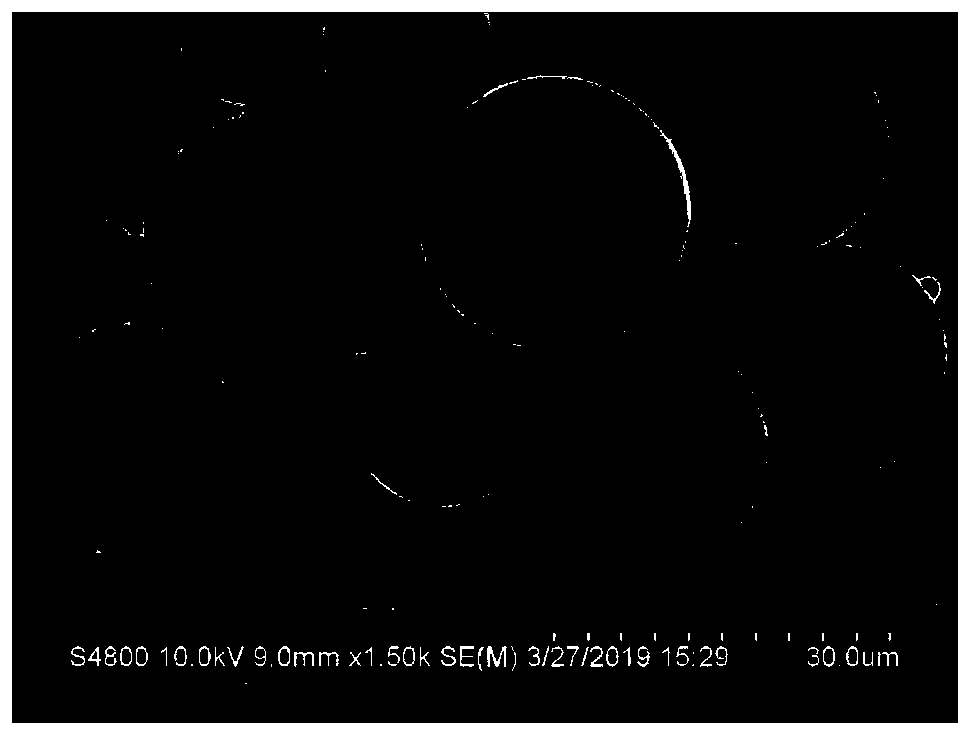

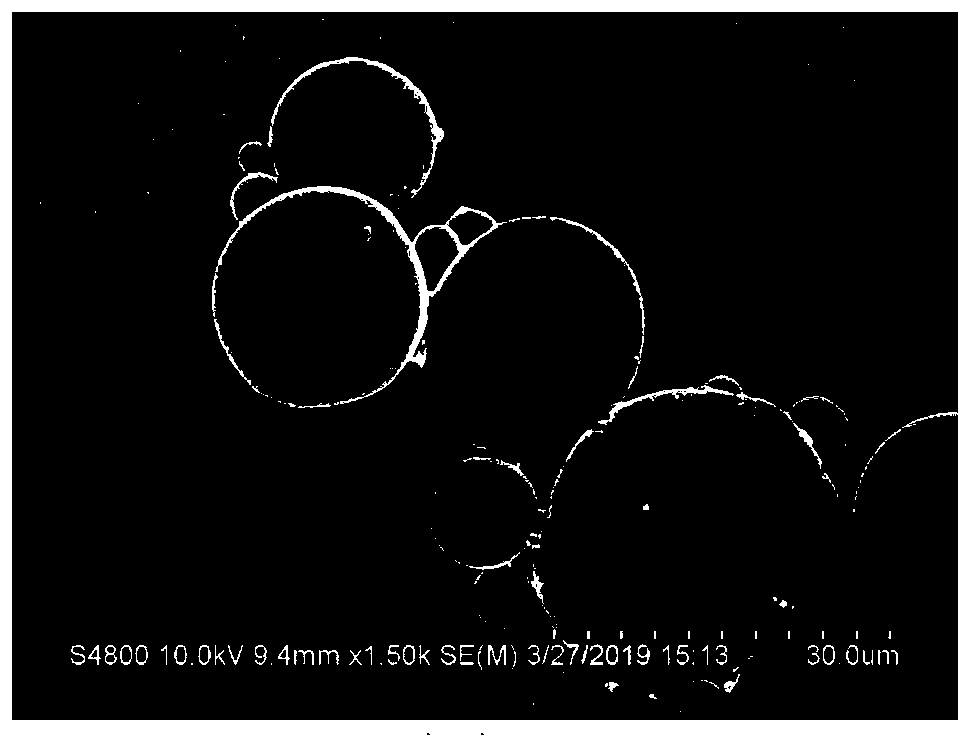

[0112] use w 1 / o / w 2 The growth factor sustained-release microspheres loaded with rhTGF-β3 in PLGA were prepared by emulsification-solvent evaporation method. The specific process was as follows: 2 μg of rhTGF-β3 was dissolved in 200 μL of deionized water to prepare an aqueous solution of rhTGF-β3 with a concentration of 10 μg / mL. Water phase w 1 . Dissolve polylactic-co-glycolic acid (PLGA) with a molecular weight of 102,000 Da in dichloromethane (DCM) to prepare a PLGA solution with a concentration of 25 mg / mL as the oil phase o. Polyvinyl alcohol (PVA) with a molecular weight of 67,000 Da was dissolved in deionized water to prepare a 1% PVA aqueous solution as the external water phase w 2 ; Dispense 200 μL of the inner aqueous phase w 1 Join in 2mL oily phase o, form primary emulsion (w 1 / o); then the primary emulsion (w 1 / o) Add 20mL external aqueous phase w 2 At room temperature (20°C-25°C), stir magnetically at 500rpm for 12 hours, volatilize and remove DCM to ...

Embodiment 2

[0114] The difference from Example 1 is that 5 μg of rhTGF-β3 was dissolved in 200 μL of deionized water to prepare a rhTGF-β3 aqueous solution with a concentration of 25 μg / mL as the internal water phase w 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com