Preparation method of SnSb nano particle/three-dimensional nitrogen-doped nano porous carbon composite material and application of SnSb nano particle/three-dimensional nitrogen-doped nano porous carbon composite material

A nanoporous carbon and nanoparticle technology, applied in electrical components, battery electrodes, circuits, etc., to achieve excellent rate performance and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

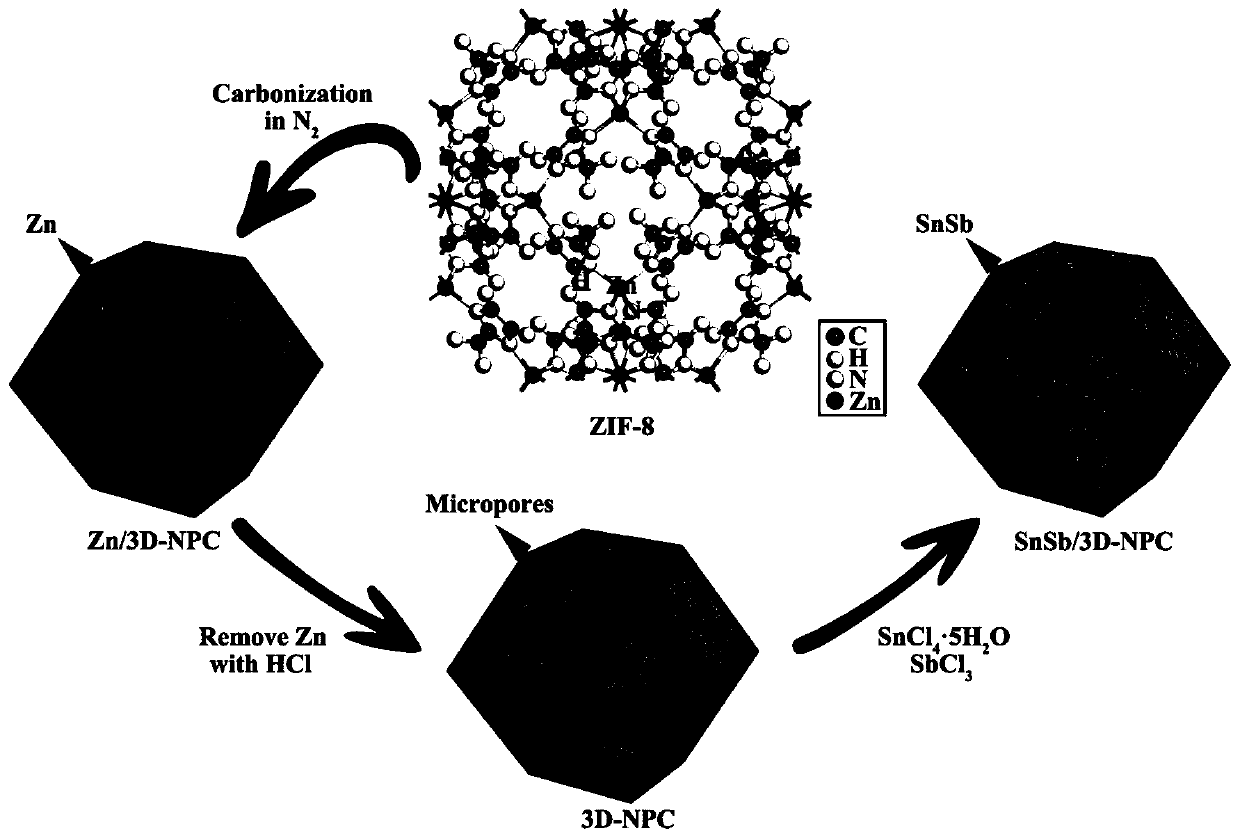

[0068] The preparation process and steps in this embodiment are as follows:

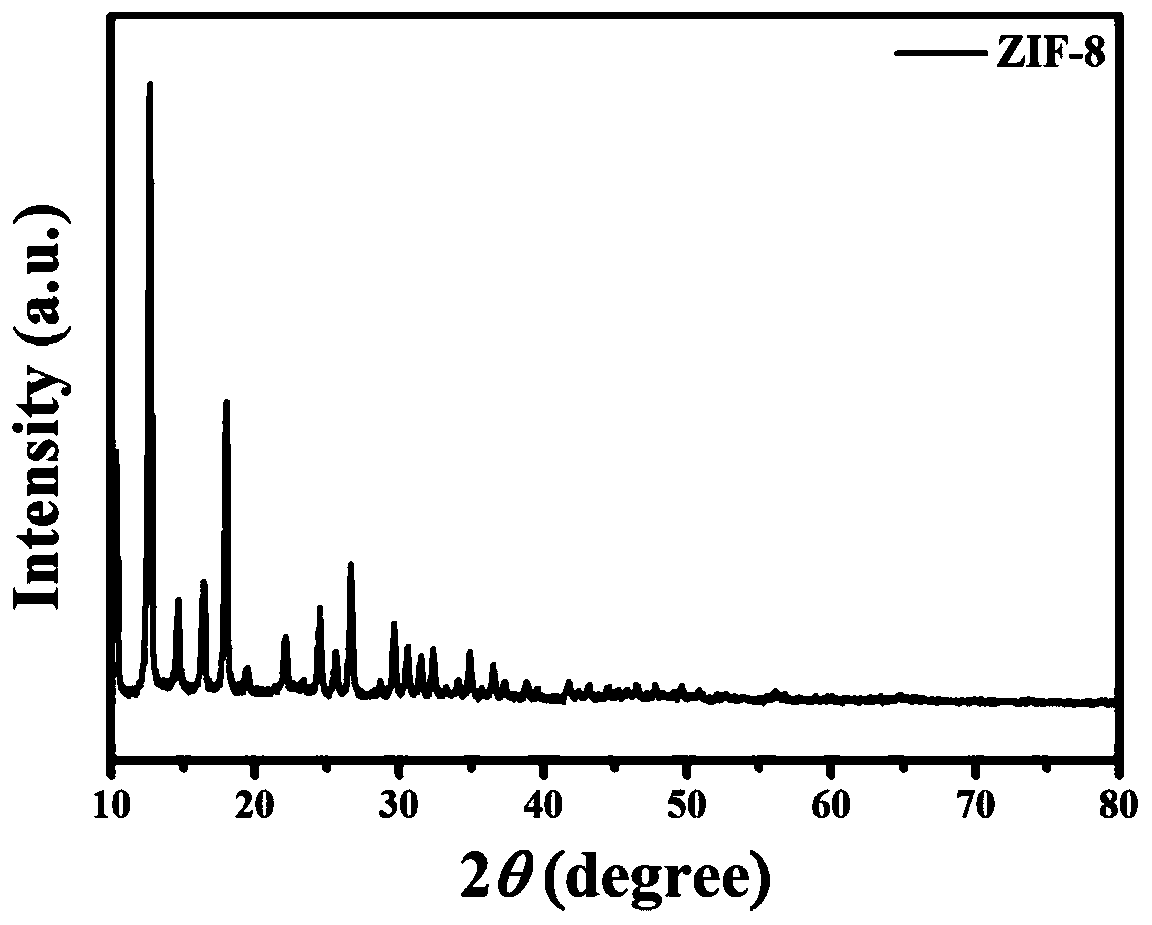

[0069] (1) Preparation of zeolite imidazole framework material (ZIF-8): 0.734g of zinc nitrate hexahydrate and 0.81g of dimethylimidazole were added to 50ml of methanol solution, stirred evenly, and after mixing the two solutions, After stirring for 24h, the product was centrifuged and dried for 10h to obtain ZIF-8.

[0070] (2) Preparation of 3D-NPC: In a tube furnace filled with argon, ZIF-8 was heated at 2°C min -1 Raise the temperature to 300°C for 2 hours, and then at 5°C for min -1 Raise the temperature to 900°C for 5 hours, then cool the product to room temperature, wash it with dilute hydrochloric acid and water for 4 times, and finally obtain 3D-NPC.

[0071] (3) Preparation of SnSb / 3D-NPC: Add 0.14g of tin tetrachloride pentahydrate, 0.091g of antimony trichloride and 0.04g of 3D-NPC into 40ml of methanol solution, stir well, and then add 0.2g of boron Sodium hydride in 2ml of methanol s...

Embodiment 2

[0098] (1) Preparation of zeolite imidazole framework material (ZIF-8): 0.734g of zinc nitrate hexahydrate and 0.81g of dimethylimidazole were added to 50ml of methanol solution, stirred evenly, and after mixing the two solutions, After stirring for 24h, the product was centrifuged and dried for 10h to obtain ZIF-8.

[0099] (2) Preparation of 3D-NPC: In a tube furnace filled with argon, ZIF-8 was heated at 2°C min -1 Raise the temperature to 300°C for 2 hours, and then at 5°C for min -1 Raise the temperature to 900°C for 5 hours, then cool the product to room temperature, wash it with dilute hydrochloric acid and water for 4 times, and finally obtain 3D-NPC.

[0100] (3) Preparation of SnSb / 3D-NPC: Add 0.07g of tin tetrachloride pentahydrate, 0.1368g of antimony trichloride and 0.04g of 3D-NPC into 40ml of methanol solution, stir well, and then add 0.2g of boron Sodium hydride in 2ml of methanol solution, stirred for 30min, and then the product was centrifuged and dried to ...

Embodiment 3

[0110] (1) Preparation of zeolite imidazole framework material (ZIF-8): 0.734g of zinc nitrate hexahydrate and 0.81g of dimethylimidazole were added to 50ml of methanol solution, stirred evenly, and after mixing the two solutions, After stirring for 24h, the product was centrifuged and dried for 10h to obtain ZIF-8.

[0111] (2) Preparation of 3D-NPC: In a tube furnace filled with argon, ZIF-8 was heated at 2°C min -1 Raise the temperature to 300°C for 2 hours, and then at 5°C for min -1 Raise the temperature to 900°C for 5 hours, then cool the product to room temperature, wash it with dilute hydrochloric acid and water for 4 times, and finally obtain 3D-NPC.

[0112] (3) Preparation of SnSb / 3D-NPC: Add 0.21g of tin tetrachloride pentahydrate, 0.046g of antimony trichloride and 0.04g of 3D-NPC into 40ml of methanol solution, stir well, and then add 0.2g of boron Sodium hydride in 2ml of methanol solution, stirred for 30min, and then the product was centrifuged and dried to o...

PUM

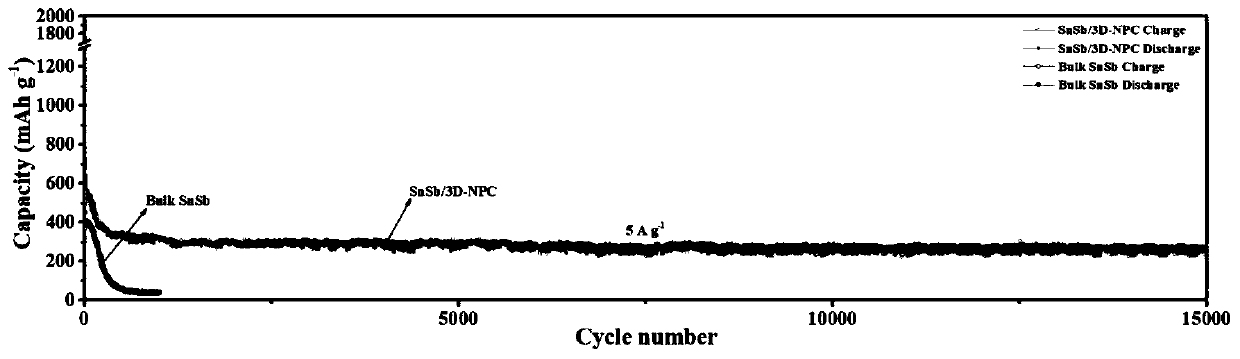

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Average discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap