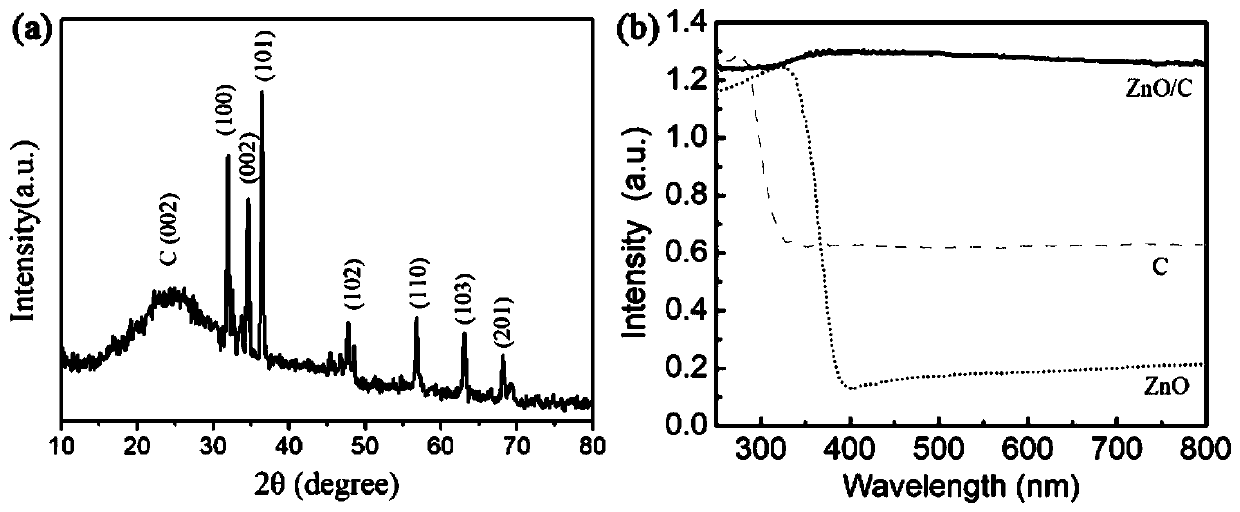

Zinc oxide/carbon composite photocatalyst and preparation method thereof

A photocatalyst and carbon composite technology, which is applied in the field of photocatalysis, can solve the problems of secondary pollution, difficulty in recycling and reusing granular photocatalysts, and achieve the effects of accelerating separation and transmission, improving photocatalytic efficiency, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the zinc oxide / carbon composite photocatalyst of the present embodiment comprises the following steps:

[0035] Add 3.0 grams of zinc acetate, 1.2 grams of polyvinylpyrrolidone, and 1.2 grams of starch into 10 grams of deionized water, stir magnetically for 3 hours to completely dissolve the zinc acetate, polyvinylpyrrolidone, and starch, and then put the solution in a refrigerator at -20°C Freeze for 5 hours to obtain a composite material of zinc acetate, polyvinylpyrrolidone, starch and ice; immediately put the frozen composite material into a freeze dryer, and freeze-dry in a vacuum at a temperature of -60°C and a pressure of 3 Pa After 48 hours, obtain a porous composite material composed of zinc acetate, polyvinylpyrrolidone and starch, i.e. an intermediate product;

[0036] The obtained porous composite material was transferred to a clean ceramic ark, then placed in a tube furnace, heated at a rate of 2 °C / min in an air atmosphere to 270 ...

Embodiment 2

[0040] The preparation method of the zinc oxide / carbon composite photocatalyst of the present embodiment comprises the following steps:

[0041] Add 4.0 grams of zinc acetate, 1.2 grams of polyvinylpyrrolidone and 0.24 grams of starch into 10 grams of deionized water, stir for 3 hours to completely dissolve the zinc acetate, polyvinylpyrrolidone and starch, and then put the solution in the refrigerator at -80 °C Freeze for 3 hours at lower temperature to obtain zinc acetate, polyvinylpyrrolidone, starch and ice composite material; immediately put the frozen composite material into a freeze dryer, and freeze-dry it for 54 hours at -60 ° C under 10 Pa to obtain zinc acetate, polyvinylpyrrolidone, and polyvinylpyrrolidone. Composite porous material composed of vinylpyrrolidone and starch.

[0042] The obtained porous material was transferred to a clean ceramic ark, then placed in a tube furnace, heated at a rate of 0.5 °C / min in an air atmosphere to 200 °C for 4 hours, and then h...

Embodiment 3

[0046] The preparation method of the zinc oxide / carbon composite photocatalyst of the present embodiment comprises the following steps:

[0047] Add 0.5 g of zinc acetate, 0.4 g of polyvinylpyrrolidone, and 2.0 g of starch into 10 g of deionized water, stir magnetically for 3 hours to completely dissolve the zinc acetate, polyvinylpyrrolidone, and starch, and then put the solution in liquid nitrogen-196 Freeze at ℃ for 2 hours to obtain zinc acetate, polyvinylpyrrolidone, starch and ice composite material; immediately put the frozen composite material into a freeze dryer, and freeze-dry at -60 ℃ for 36 hours under 10 Pa to obtain zinc acetate, Composite porous material composed of polyvinylpyrrolidone and starch;

[0048] The obtained composite porous material was transferred to a clean ceramic ark, then placed in a tube furnace, heated at a rate of 10 °C / min to 300 °C for 1 hour in an air atmosphere, and then heated at 10 °C in a nitrogen atmosphere. The temperature was rais...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com