Method for preparing superhydrophobic oil-water separation mesh membrane in one step

An off-grid, super-thin technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of copper mesh surface roughness, expensive fluorine-containing reagents, complex preparation process, etc., and achieve chemical resistance and mechanical Good performance, easy cleaning and storage, and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Ultrasonic clean the 400-mesh copper mesh with acetone, ethanol and deionized water for 15 minutes to remove surface oil, then put the copper mesh in 6mol / L HCl solution for 10 minutes, wash with deionized water, and dry spare;

[0022] (2) Add 0.57g of stearic acid to 100mL of absolute ethanol, put it into the copper mesh treated in step (1) after dissolving, and react at room temperature for 48h; take out the omentum, rinse the residual solution on the surface with absolute ethanol, and naturally Dry to obtain the super-hydrophobic oil-water separation omentum.

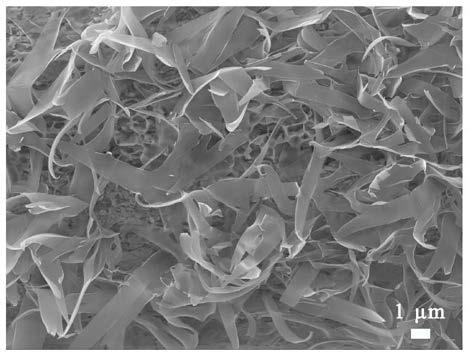

[0023] The surface topography scanning electron microscope photo of the superhydrophobic oil-water separation omentum prepared in the present embodiment is as follows figure 1 shown;

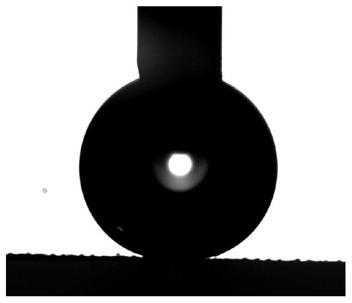

[0024] It is 159 ° (as figure 2 shown);

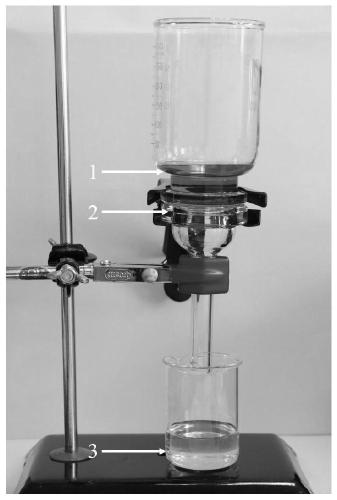

[0025] use image 3 The experimental device shown is used for separation experiments on the superhydrophobic oil-water separation membrane prepared in this example. The oil-w...

Embodiment 2

[0027] (1) Ultrasonic cleaning of foamed nickel with a 0.2 mm aperture for 15 minutes with acetone, ethanol and deionized water respectively to remove surface oil stains, then ultrasonic cleaning of foamed nickel in 4mol / L HCl solution for 15 minutes, followed by deionized water cleaning, drying spare;

[0028] (2) Add 0.69g of myristic acid to 60mL of absolute ethanol, put it into the nickel foam treated in step (1) after dissolving, and react at room temperature for 24h; take out the omentum, rinse the residual solution on the surface with absolute ethanol, and naturally Dry to obtain the super-hydrophobic oil-water separation omentum.

[0029] The contact angle of the superhydrophobic oil-water separation omentum prepared in this embodiment to 5 μL water droplets is greater than 150° in air;

[0030] use image 3 The experimental device shown is used for separation experiments on the superhydrophobic oil-water separation membrane prepared in this example. Fix the oil-wat...

Embodiment 3

[0032] (1) Ultrasonic cleaning of foam iron with a 0.1 mm pore diameter for 15 minutes with acetone, ethanol and deionized water respectively to remove surface oil stains, then ultrasonic cleaning of foam iron in 3mol / L HCl solution for 25 minutes, and deionized water cleaning, drying spare;

[0033] (2) Add 1.28g of palmitic acid into 50mL of absolute ethanol, put it into the iron foam treated in step (1) after dissolving, and react at room temperature for 12h; take out the omentum, rinse the residual solution on the surface with absolute ethanol, and naturally Dry to obtain the super-hydrophobic oil-water separation omentum.

[0034] The contact angle of the superhydrophobic oil-water separation omentum prepared in this embodiment to 5 μL water droplets is greater than 150° in air;

[0035] use image 3 The experimental device shown is used for separation experiments on the superhydrophobic oil-water separation membrane prepared in this example. Fix the oil-water separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com