Termite-resistant concrete and preparation method thereof

A technology for concrete and chlorpyrifos is applied in the field of anti-termite concrete and its preparation, termite control, and can solve problems such as erosion and damage, and achieve the effects of improving the validity period, simple process and solving engineering problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

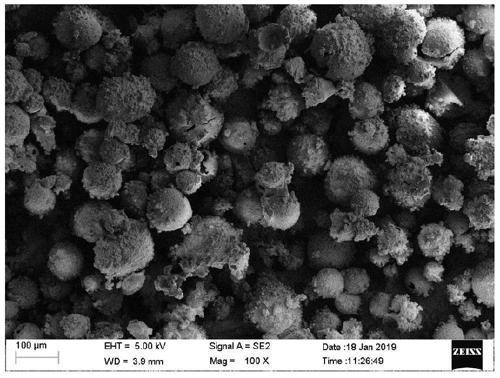

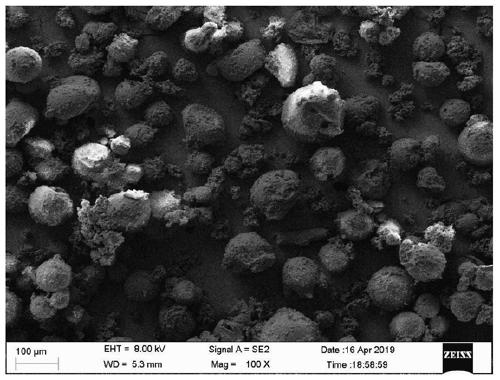

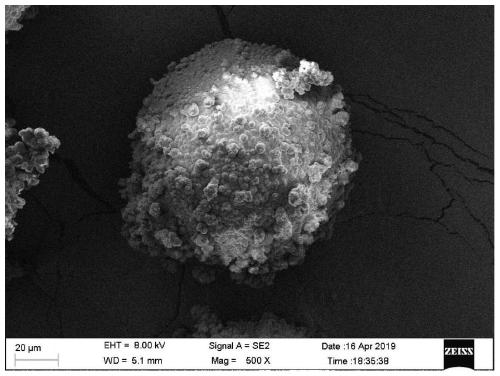

Image

Examples

preparation example Construction

[0036] The preparation method of chlorpyrifos microcapsules comprises steps:

[0037] The first step prepares urea-formaldehyde resin prepolymer;

[0038] In the second step, the former drug of chlorpyrifos is dissolved in xylene solution, and then an emulsifier is added to obtain a chlorpyrifos emulsion;

[0039] The third step is to mix the chlorpyrifos emulsion with the urea-formaldehyde resin prepolymer, slowly adjust the pH value of the mixture to 2.0-3.0, and carry out the acidification stage of the in-situ polymerization reaction;

[0040] In the fourth step, the curing agent is added into the mixed solution to carry out the curing stage of the in-situ polymerization reaction to obtain chlorpyrifos microcapsules with urea-formaldehyde resin as the wall material.

[0041] In the first step, urea and formaldehyde aqueous solution with a molar ratio of 1:1.75 are mixed to adjust the pH value to 8.0-9.0, specifically, triethanolamine is used to adjust the pH value. Raise ...

Embodiment 1

[0056] Preparation of Chlorpyrifos Microcapsules.

[0057] In the first step, 6g of urea and 14.1g of formaldehyde solution with a mass fraction of 37%, n(urea):n(formaldehyde)=1:1.75, are added to a 500ml Erlenmeyer flask, stirred to fully dissolve urea, and adjusted with triethanolamine The pH of the solution was 8.0-9.0, and then refluxed and stirred at a speed of 450 rpm in a constant temperature water bath at 70° C. for 1 hour to obtain a urea-formaldehyde resin prepolymer.

[0058] In the second step, the former drug of 18g chlorpyrifos is dissolved in 6g benzene, and 1.2g styrene-maleic anhydride copolymer and 0.3g polyvinyl alcohol emulsifier are weighed in addition, mixed with the previously prepared urea-formaldehyde resin prepolymer, Under constant temperature water bath at 40°C, stir at 800rpm for 30-40min to obtain a stable chlorpyrifos emulsion.

[0059] The third step is to dissolve 0.4g NaCl with a certain amount of distilled water, add it to the mixture of ch...

Embodiment 2

[0070] Embodiment 2 is roughly the same process as Embodiment 1, but the stirring speed is changed to 600rpm and 500rpm respectively in the emulsification stage and acidification stage in the preparation of chlorpyrifos microcapsules. And the amount of microcapsules in concrete increased from 86.08g to 172.16g. Specific steps are as follows:

[0071] Preparation of Chlorpyrifos Microcapsules.

[0072] In the first step, 6g of urea and 14.1g of formaldehyde solution with a mass fraction of 37%, n(urea):n(formaldehyde)=1:1.75, are added to a 500ml Erlenmeyer flask, stirred to fully dissolve urea, and adjusted with triethanolamine The pH of the solution was 8.0-9.0, and then refluxed and stirred at a speed of 450 rpm in a constant temperature water bath at 70° C. for 1 hour to obtain a urea-formaldehyde resin prepolymer.

[0073] In the second step, the former drug of 18g chlorpyrifos is dissolved in 6g benzene, and 1.2g styrene-maleic anhydride copolymer and 0.3g polyvinyl alc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com